2021-12-10

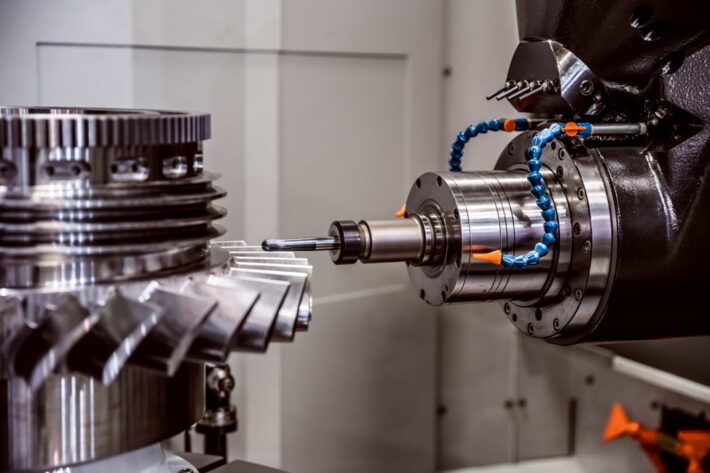

5 Tips for Improving your CNC Milling Machine Skills

Source: thomasnet.com

The CNC machinery is utilized in a number of different industries, and knowing how to use these devices is the key to a successful business and a lot of profits. If you are a beginner or if you think that there are things that you need to do to become better, you’ve come to the right place. In this article, we are going to give you some tips for improving your CNC milling machine skills. Keep on reading if you want to learn how to avoid making mistakes and how to improve the quality of your goods.

1. Knowing MDI is going to help you

Source: thomasnet.com

Manual Data Input is going to save you a lot of time, trouble, and resources in the long run, and you should take some time to learn and master this part of your CNC milling machine. You can see the MDI part in the control panel of your device, and knowing your way around it can help you out a lot.

When you understand it, and when you know a bit more than the basics of it you will be able to make unique adjustments and control where the cutter is going to go. Know that the learning process is not difficult at all, and if you focus on it, you can master it pretty easily.

2. The cutters you use are going to make a difference

We all know that we get what we’ve paid for, and when it comes to these devices, the same is 100 percent true. If you don’t want to bother with parts that are going to get easily damaged or broken, you need to invest in quality.

There are a lot of different types of cutters that you can find on the market, and their price and specifications are going to greatly vary. You need to invest in something of high quality and know that when you get items that are durable and reliable, you are going to avoid a lot of issues, stress, and poorly made components.

This does not mean that you have to purchase the most expensive product that you see on the market, but you should steer away from the cheapest goods that sound too good to be true. Spending less money on this means that you will have to spend far more in the long run.

3. Make sure you have all the right components

Source: worthyhardware.com

Now let’s talk about the components that you are going to need to ensure the success of your project. The first thing you are going to need is a vise, and this part needs to be of high quality so that it can last for years. Note that a low-quality vise is not going to hold your parts in the right position, they will shift while the machine is working, and that will lead to errors and damages.

You will also think about investing in the right type of parallels and you should not forget about the clamping kit. Even though these tools and components seem like they are not as important, in reality, if your parts are not properly fastened, and if they move around or fall off, you will have a lot of delays with your production process.

According to Yihkuan, you also need to think about the milling head and the exact type you need, so that you can ensure the quality of your project. There are a lot of different options available on the market, so take your time to learn the differences, and how the milling head is going to benefit you.

4. Put some time and effort into the programming

Source: ctemag.com

CDC programmers can make a lot of difference not only during the production process but also with time management and customer satisfaction. If you are interested to go one step beyond and if you want to improve your overall skills, then you need to put some time and effort into CNC programming.

There are several ways that you can do this, and the first one is enrolling in an online course, or you can just follow tutorials. This is the easiest and usually the cheapest method, even though you may not get all the knowledge that you could utilize. You could also choose a college course that will help you out, but you should know that this is going to take you a bit more time than you may want to invest. However, after this, you are going to get a degree that will help you both now and in the future. In addition to all these, you can also choose to get an apprenticeship where you can learn from people who already know everything about the process, and you can find yourself a mentor.

5. Be careful of the materials you use

Source: silvergateengineering.in

Our last tip for you is going to be regarding the materials you use. As you already know, different types of milling machines are good for different projects, and some of them can be extremely versatile and be able to cur through a number of different materials.

Nevertheless, you need to be smart, especially if you are a beginner. It is recommended that people who are first learning how to use these devices should steer away from stainless steel, and they should instead opt for things like brass and aluminum.

Harder metals are going to test your skills, and chances are, you will fail from making all the right things you want to. These metals are usually more difficult to work with, and even though it is not impossible, you still need to be confident and know what you are doing. Start with softer metals that are much more forgiving and that can produce beautiful goods with ease.

These are some of the things that can help you improve your skills and that will make your job easier. Know that everything takes time, so you need to be patient with yourself and learn from your mistakes. You cannot master this device in a week, so be ready to try and fail, and know that with time you are going to create much better pieces and have more successful projects.