2021-12-16

Everything you need to know about CNC drilling

Productivity and precision are a priority for numerous industries out there. Due to the same reason, computer numerical control, or CNC, is quite popular among such industries. It is possible to use CNC for metal drilling work. When a company wants to drill a hole or any other shape with a specific length or diameter, CNC drilling will provide much-needed assistance. This will eventually help you to be equipped with a universal set of parts, which will ensure performance, safety, and reliability.

How does CNC drilling work?

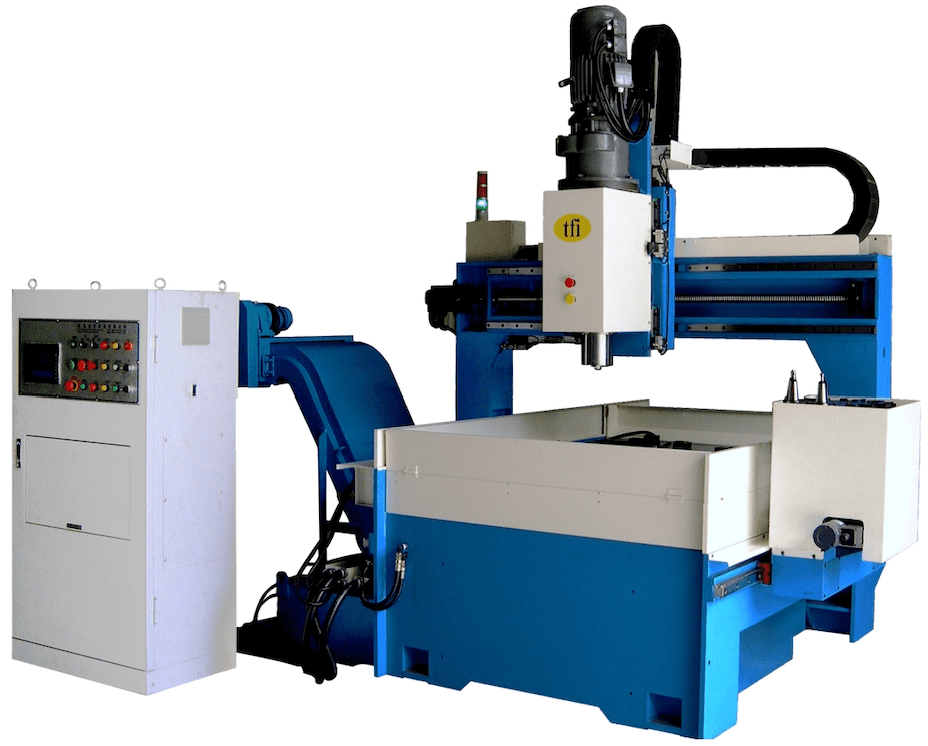

A CNC drilling machine is needed for CNC drilling work. There are many different types of CNC drilling machines available for purchase out there. They include radial CNC drilling machines, bench CNC drilling machines, and upright CNC drilling machines. It is up to you to take a look at your needs and go ahead with the most appropriate type of CNC drilling machine available. Then you can expect to receive all great benefits coming along with it.

There are multiple steps to use a high speed drilling machine and get work done. As the very first step, operator of the gantry drilling machine or CNC drilling machine would upload CAD (Computer Aided Design). Along with that, CAM (Computer Aided Manufacturing) file will also be added. Then the operator will go ahead and install an appropriate drill bit, which is securing the materials onto the top of the table. This is where the operator would begin the drilling process. It will be done via an interface or control panel. The spindle would then lower and holes with appropriate diameters will be created.

What are the benefits of using a CNC drilling machine?

A CNC drilling machine is capable of delivering multiple benefits. Here are some of the most prominent reasons on why people use CNC drilling machines for industrial applications.

- They offer a high level of accuracy

A CNC drilling machine is capable of delivering a high level of accuracy. You will not be able to secure such an excellent level of accuracy from anywhere else. Due to the same reason, CNC drilling machines are popular across multiple industries. By using a CNC drilling machine, it is possible to boost overall productivity. On the other hand, it is possible to optimize the production lines and reduce expenses in the long run as well.

- Ability to reproduce

Another great benefit that you can get out of a CNC drilling machine would be the ability to reproduce. This is one of the continuous challenges that a company will have to face when manufacturing products. At the time of manufacturing custom products, the ability to reproduce would play a major role. While using a CNC drilling machine, it is possible to secure an imperfection free and a consistent product line at the end of the day.

- Versatility

It is also important to be mindful about the versatility of CNC drilling machines. You will be able to use a CNC drilling machine to accept numerous bits. It is true that an operator will come across the need to use different types of drilling machines for different purposes. However, it will still be possible for them to equip a series of bits t o the drilling machine. Some of the drilling machines would offer a tool turret, which can deliver quick shuffling in between bits.

Keep these benefits in your mind and get the most out CNC drilling machines available out there. The amount you invest to buy a one will never be a waste of money.

Products

Plate Drilling Machine

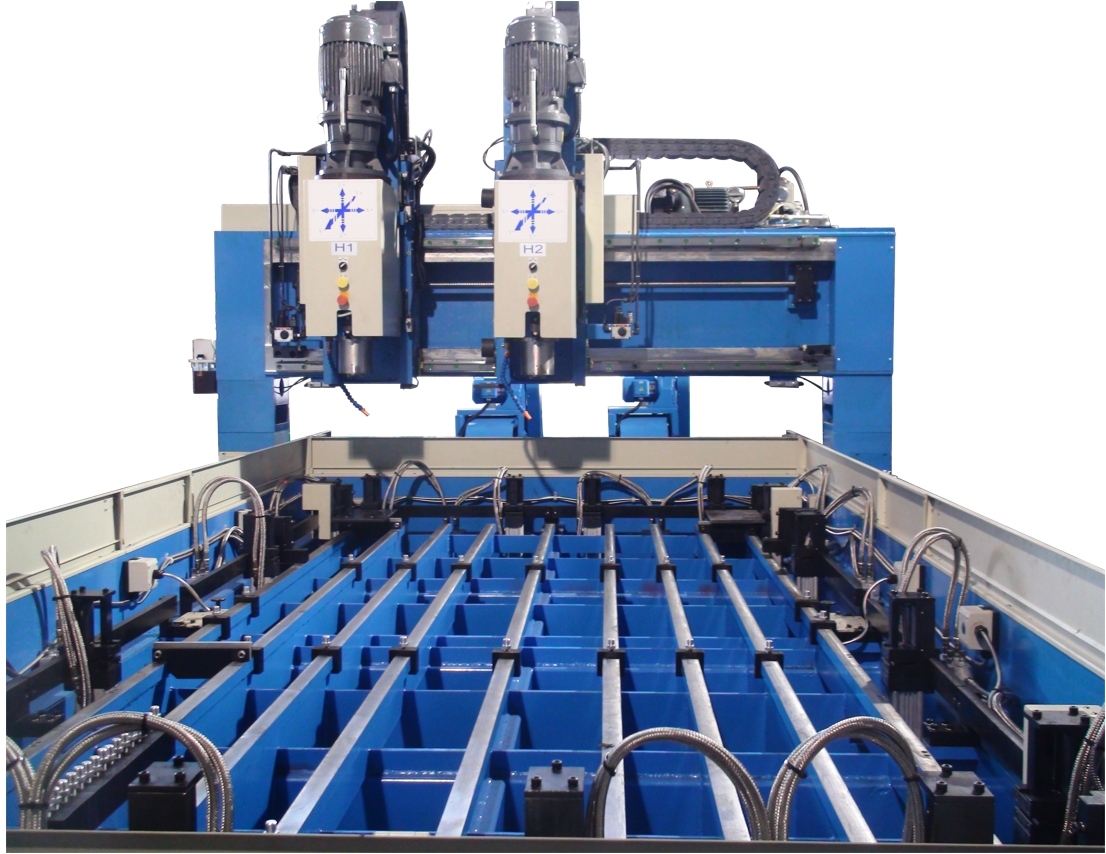

Rail Type Bridge Plate Drilling Machine

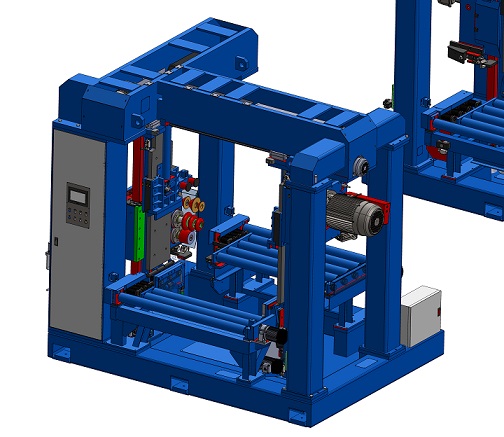

Beam Line Drilling Machine

Laser Marking Machine

- H-Beam Bevelling machine

Products - Plate Drilling Machine

- Rail Type Bridge Plate Drilling Machine

- Beam Line Drilling Machine

- Laser Marking Machine

- Beam line stamper

- H-Beam Scallop & Beveling machine

- Plate beveling machine

- Auto Arm Welder

- Pipe Notcher

- Drill Grinder

- Magnetic Core Drilling Machine

- Remolift

- Shear Wrench

- H-Beam Rotater