2021-12-23

What is a belt skimmer all about?

Oil skimmers are widely used in the machine sector because they aid in the removal of grease and oil. There are several different kinds of oil skimmers on the market. Belt skimmers have a significant position among them. Continue reading to learn more about what a belt skimmer is and what it can do for you.

What is a belt skimmer?

Belt skimmers or belt-type skimmers are the most popular skimmers that people use out there in the industrial world. You will be able to use them along with machine tools in order to get rid of floating tramp oil out of coolant surfaces. It is important for you to be mindful about the purity and effectiveness of coolants. That’s why you need to think about using a belt skimmer.

All the machine tool manufacturers out there tend to include belt skimmers along with the machines that they produce. When you take a look at a machine tank, you will be able to discover tramp oil floating at all times. The indication of tramp oil within the coolant indicates that it is not so effective. This is why you should think about using the belt skimmer to make the coolant effective.

How does a belt skimmer work?

As you get hold of a belt skimmer, you should also figure out how it would work. An unending belt of synthetic material or corrosion-resistant steel, commonly polyurethane, is used in belt-type oil skimmers. This belt travels through a pulley system that maintains tension on the belt. This belt and pulley system is powered by a tiny, geared motor.

The floating oil adheres to the belt material, and when the oil skimmer motor turns on, the oily belt spins, causing the oil to rise. The belt then runs through oil-scraping wiper blades.

Important things to be mindful about as you use a belt skimmer

There are some important facts that you need to be mindful about as you use a belt skimmer. Let’s take a look at the most prominent factors out of them.

A widespread misperception is that you may save money by purchasing a smaller skimmer with a lower lit-per-hour skimming capability. Purchasing a little or mini-unit instead of getting an industrial-sized skimmer, on the other hand, might be useless. Oil skimmers should be chosen based on their surface area rather than the volume of oil cleaned. The safety of at least two should be considered when building an oil skimming system.

In a belt type oil skimmer, the metalworking or cooling fluid remains stationary as the skimmer rolls over its surface. The fact that the coolant remains stationary is the fundamental cause of its decomposition since it promotes bacterial development. As a result, by their very design, belt oil skimmers fall short of their goal.

Oil skimming will not be possible if the coolant tank does not enable the oil can rise and float. Users of belt oil skimmers should make sure that the position on the coolant tank allows adequate time for the oil to float. As a result, requires a low coolant tank is ineffective for a belt-type oil skimmer.

It is critical to place the belt skimmer in the proper area for any belt oil skimmer system to be as successful as feasible. The tail pulley should be buried two inches underneath the coolant surface, and the belt oil skimmers should be situated opposite the inflow.

A steady coolant surface is required for belt oil skimmer to function properly. The oil film will be broken by a turbulent coolant surface, and the oil would not rise and floating on the surface. As a result, while the machine is operating, belt oil skimmers are useless. The belt skimmer, on the other hand, cannot remove oil quickly enough when the coolant is stationary while the machine is not working due to its design.

Oil Mist Collectors

Economically efficient S series

Economically efficient S series

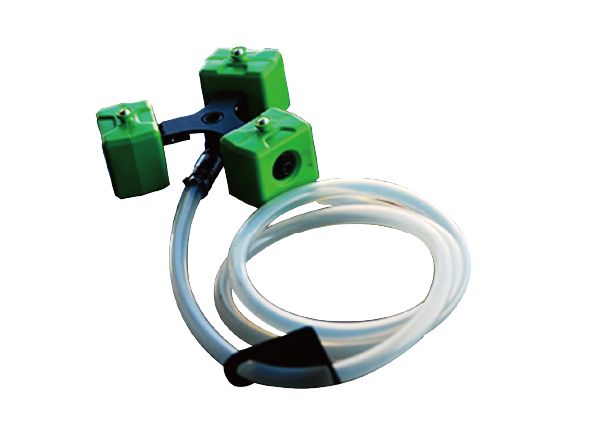

Smart Alert Flagship Series

Smart Alert Flagship Series Oil Skimmer Ultra 90

Oil Skimmer Ultra 90 Oil skimmer Ultra 360

Oil skimmer Ultra 360 Oil skimmer Ultra 1200

Oil skimmer Ultra 1200 FC Series

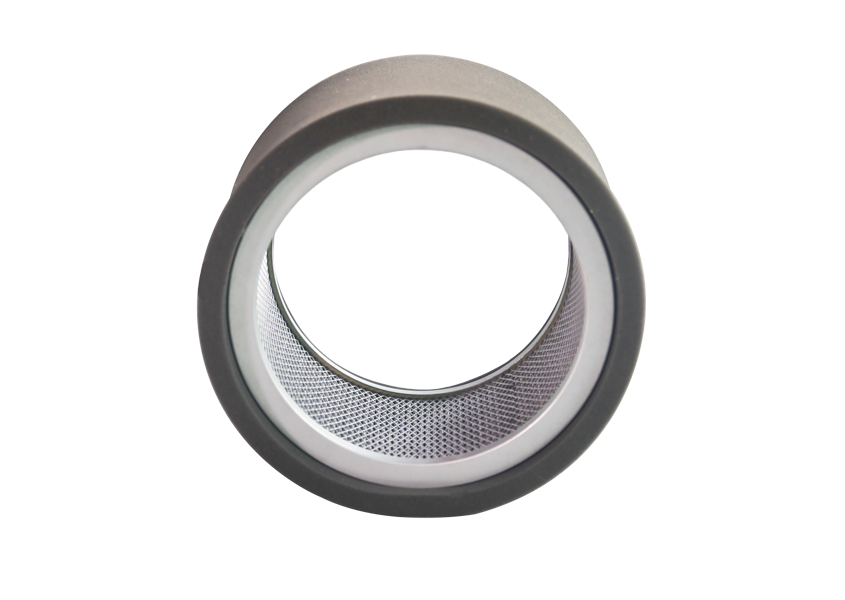

FC Series Precision filter FCG-105

Precision filter FCG-105 Precision filter FCG-105 AUTO

Precision filter FCG-105 AUTO S.T.P.M module

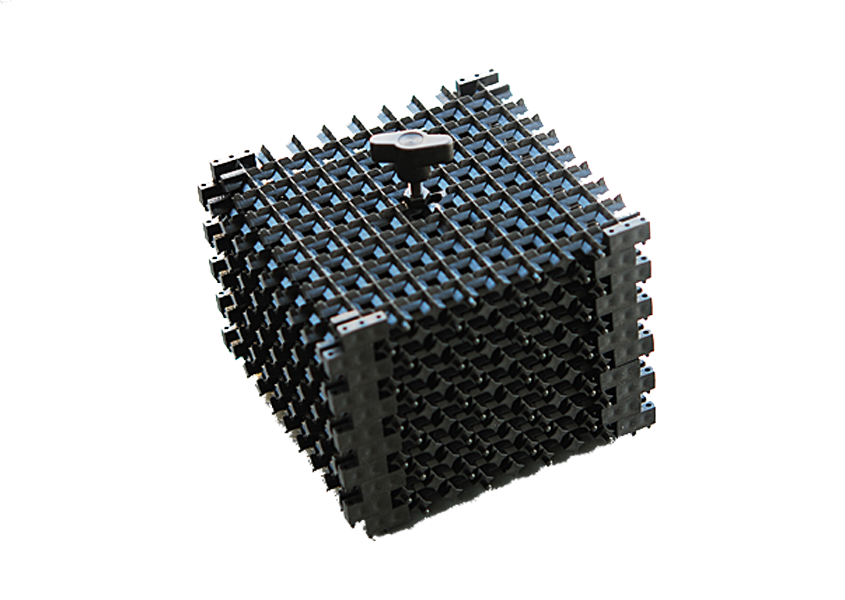

S.T.P.M module Floating Skimmer

Floating Skimmer Adjust Skimmer

Adjust Skimmer High efficiency filter tube

High efficiency filter tube Double open filter

Double open filter FCG series filter

FCG series filter