2022-07-04

Machine accessories

The most commonly used machine tool accessory of milling head, it is the important part of accessory for the machine tool to make sure the high performance of machining.

The following key points are how PARA MILL’s milling head apply to high performance machining of milling head:

l Cast

Adopt Meehanite cast iron for the major cast iron for the cast.

Meehanite cast iron after stress relief is effetely stabilized milling head and keeps machining precision in standard.

l Gears

Adopt SCM415 Alloy Steel, quenching and grinding to JIS 1st grade.

l Transmission shaft

Adopt SCM415 Alloy Steel, quenching and grinding to JIS 1st grade.

l Guide way

Adopt surface hardening, heat treatment, and grinding that ensure surface is precise and durable.

l Spindle

Heavy-duty cutting spindle with taper NT50/BT50

Brief, these key points made PARA MILL’s milling head lives more than 30 years, even milling head 30 years ago still remains on machining duty. Therefore, following the principles of “Diligence, Honesty, and Reliability,” we make an all-out effort to maintain our professional image and to provide top-notch double-sided milling machines, horizontal milling machines, and milling head units. Many years have passed since we began, and we have become highly reputed as reliable.

Optional equipment

- Pneumatic Tool Lock

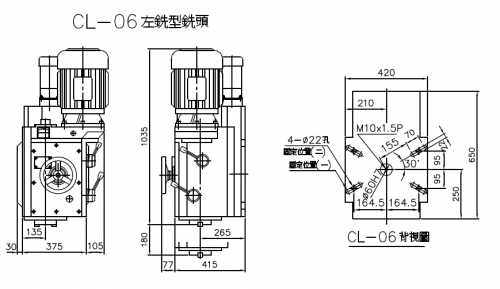

- CL-06, CL-09, With 3/ AC motor for feeding device

- Ball Screw

- Air Balancer

- Max. Cutter Dia. Can be up to 315 mm

SPECIFICATIONS

| Spindle Motor | 10 HP x 4P | |

| Spindle Taper | NT-50# | |

| Spindle End O.D. | ф128.57 | |

| Spindle Speed | 6 step | |

| Spindle Speed (RPM) | 50 HZ | 76.120.168.250.335.501 |

| 60 HZ | 93.145.203.303.406.608 | |

| Max. Cutter Dia. | 200 mm | |

| Work Travel | 300 mm | |

| AC Motor | 1/4 HP x 1/25 | |

| Rapid Speed | 360 mm/min | |

| Hand Wheel | 2 mm/rev | |

| Weight | 420 kg | |