Products

Smart & Easy

Plentiful cutting technologies、Friendly interface、Remote、Conventient feature.

High Speed reliable AWT

High speed reliable AWT、 Threading in the slot、Threading under water、 Reduce human resource cost when machining multi modles.

Enhance Machining Performance

DPM Module、Discharging Stabilizer、New strategy for corner control、Manual radius size machining、Reduce wire marks from approach cutting、New micron finish circuit.

Power Saving and Low Cost Operation

Intelligent power management、Compensation of wire consumption、Easy to maintain and reduce cost for service.

Machine feature

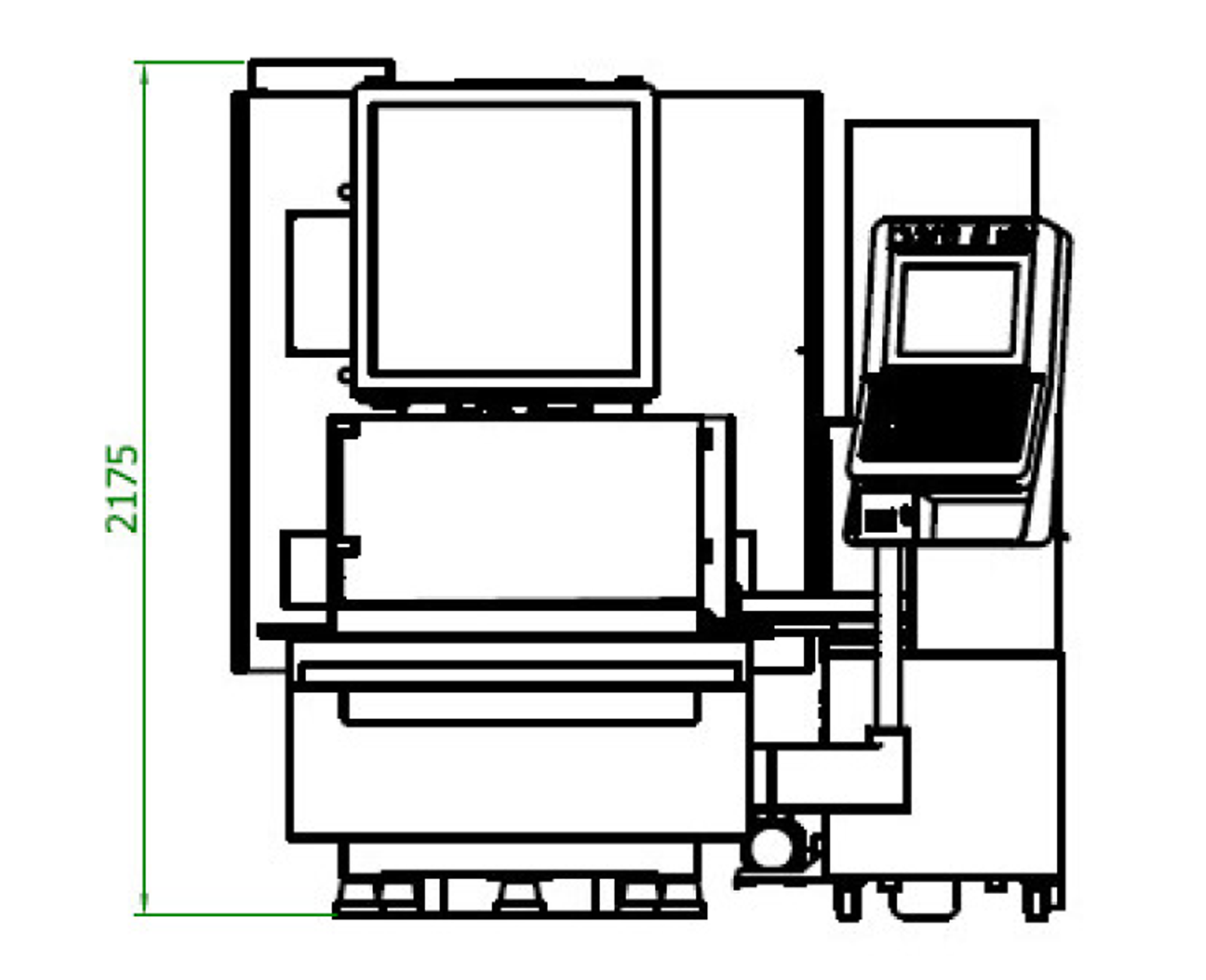

1. Rigid U, V truss design

2. Stainless steel work table with hardness HRC 50°.

3. High response AC servo motor for guaranteed accuracy

4. Extra wide machine base.

To ensure thremal balance, RIB location is designed by finite element analysis (FEA)assuring and optimized rigid structure.

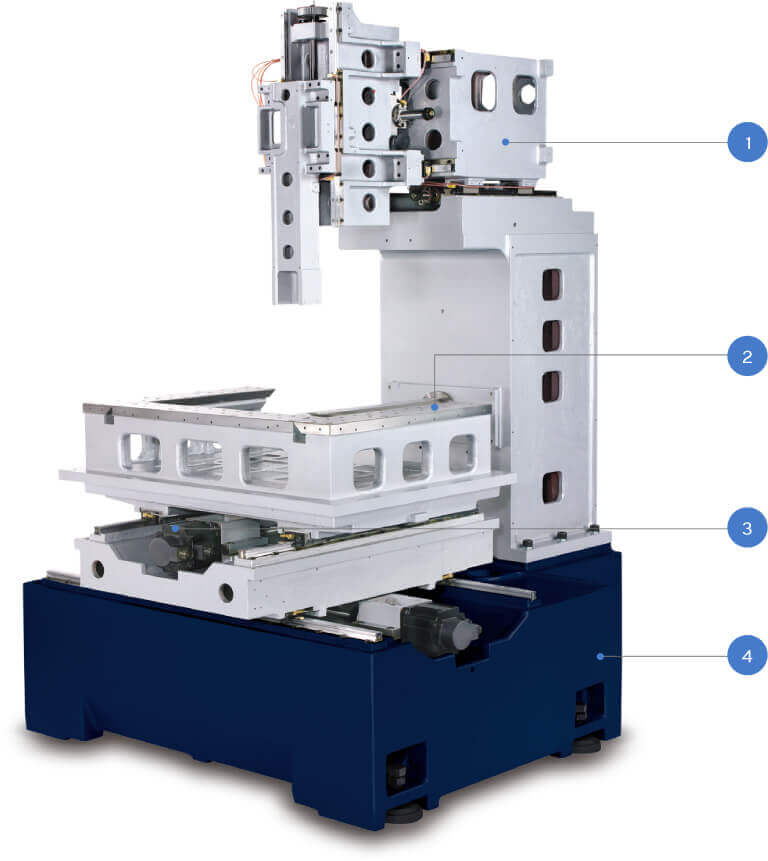

Water cooled lower arm prevents thermal expansion caused by heat buildup. Therefore the accuracy will be improved.

A rugged cast iron machine structure is the foundation of precision.

Specification

VG400

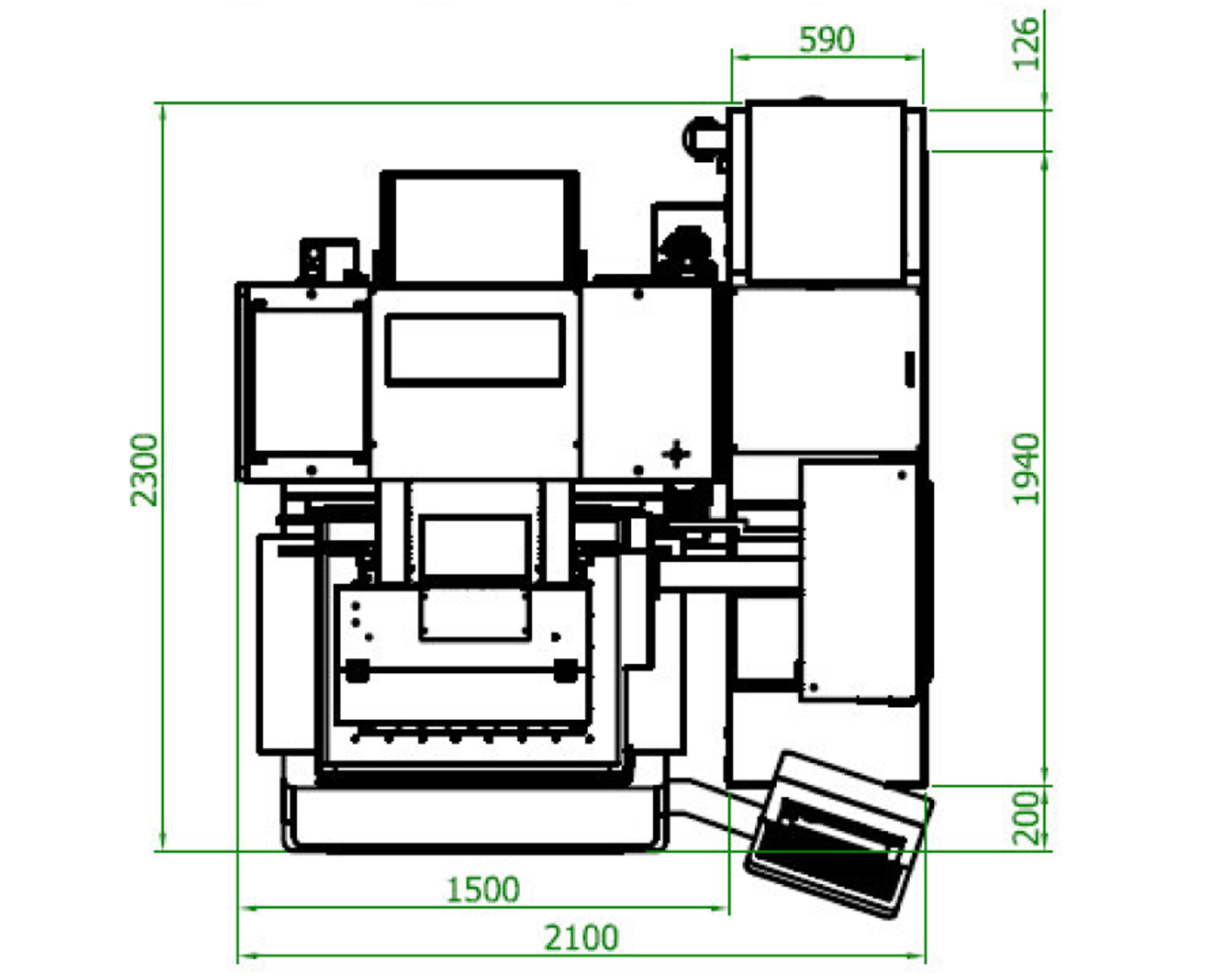

Machine size: 2100 x 2300 x 2200 mm

Travel of X/Y axes: 400 x 300 mm

Travel of U/V axes: 80 x 80 mm

Travel of Z axis: 220 mm

Number of axes controlled: 5 Axis AC servo motor

Maximum taper angle: ±22°/ 100mm with wide diamond guide and nozzle

Machine weight: 2700 kg

Standard Accessories

- Ion exchange resin x 10L

- Paper filter x 2 pcs

- Diamond guide x 2 pcs

- Upper and lower flushing nozzle x 2 sets

- Energizing plates x 2 pcs

- Brass wire x 1 spool

- Clamping tool x 1 set

- Vertical alignment jig x 1 set

Options

- XY axis linear scale

- W-Axis

- Clamping Beam

- Jumbo Feeder L-50A

- AWT

- Double Door

- AVR 15KVA

- Power Slide Door

- (Only V650G & V850G)

- Transformer 15KVA

- Signal Tower

- Short Message Service (SMS)

- Remote Monitor System

- Super Finish Circuit