Products

Comply with TUV CE comformity, both safety and desired design with easy operation.

High Precision

Smart Corner Control, Stable Discharge processing, Super Finish Circuit (SFC) provide more accuracy.

Efficiency

DPM module, Precision mark control, Electrolysis Free(EF) generator system.

Cost effective

Intelligent access control, Reduce Wire Consumption, Economic concerned price.

Intelligent Networking

Remote monitor management, Controller connector, Portable device monitor.

Automation

High speed Auto Wire Threading, Robo-arm transfer of Workpiece, Probe Auto Measurement and Correction

Machine feature

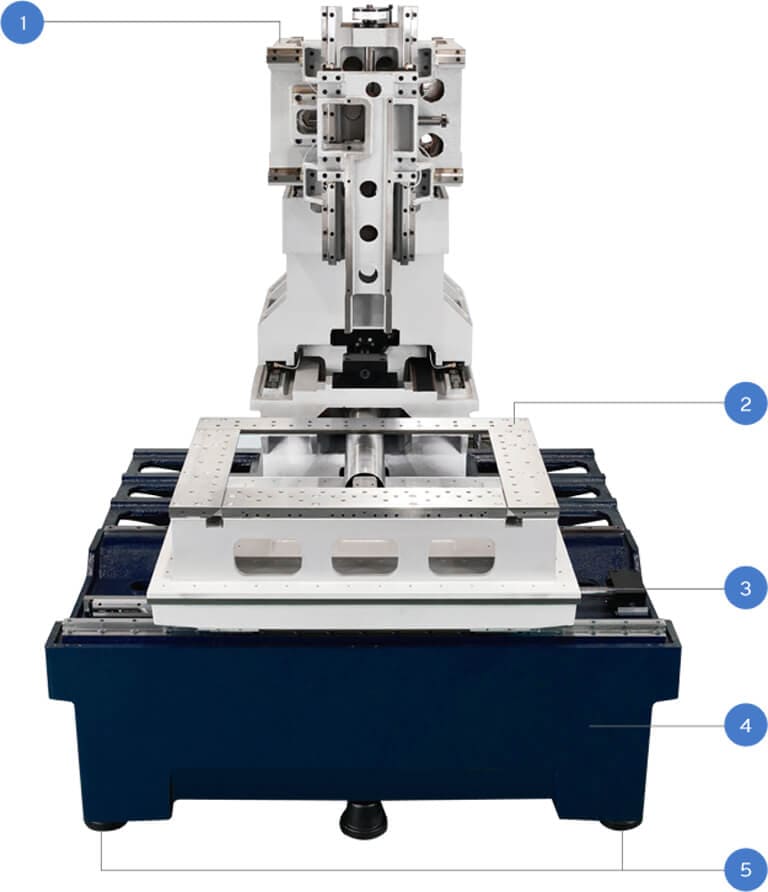

1. Rigid U, V truss design

2. Stainless steel worktable with hardness HRC 50°.

3. Machine Casting is designed based on the FEA analysis for increasing the rigidity.

4. Machine base with extra wide.

Specification

NP500L (Submerged Type)

Max. work piece size: 850 x 550 x 300 mm

Wire diameter: 0.15 - 0.3 mm

Max. work piece weight: 600 kg

Number of axes controlled: XY axis linear motor, UV Z axis AC servo motor

Table travel of X Y: 500 x 300 mm

Maximum taper angle: ±26°/ 100mm with wide diamond guide and nozzle

U & V axis travel: 120 x 120 mm

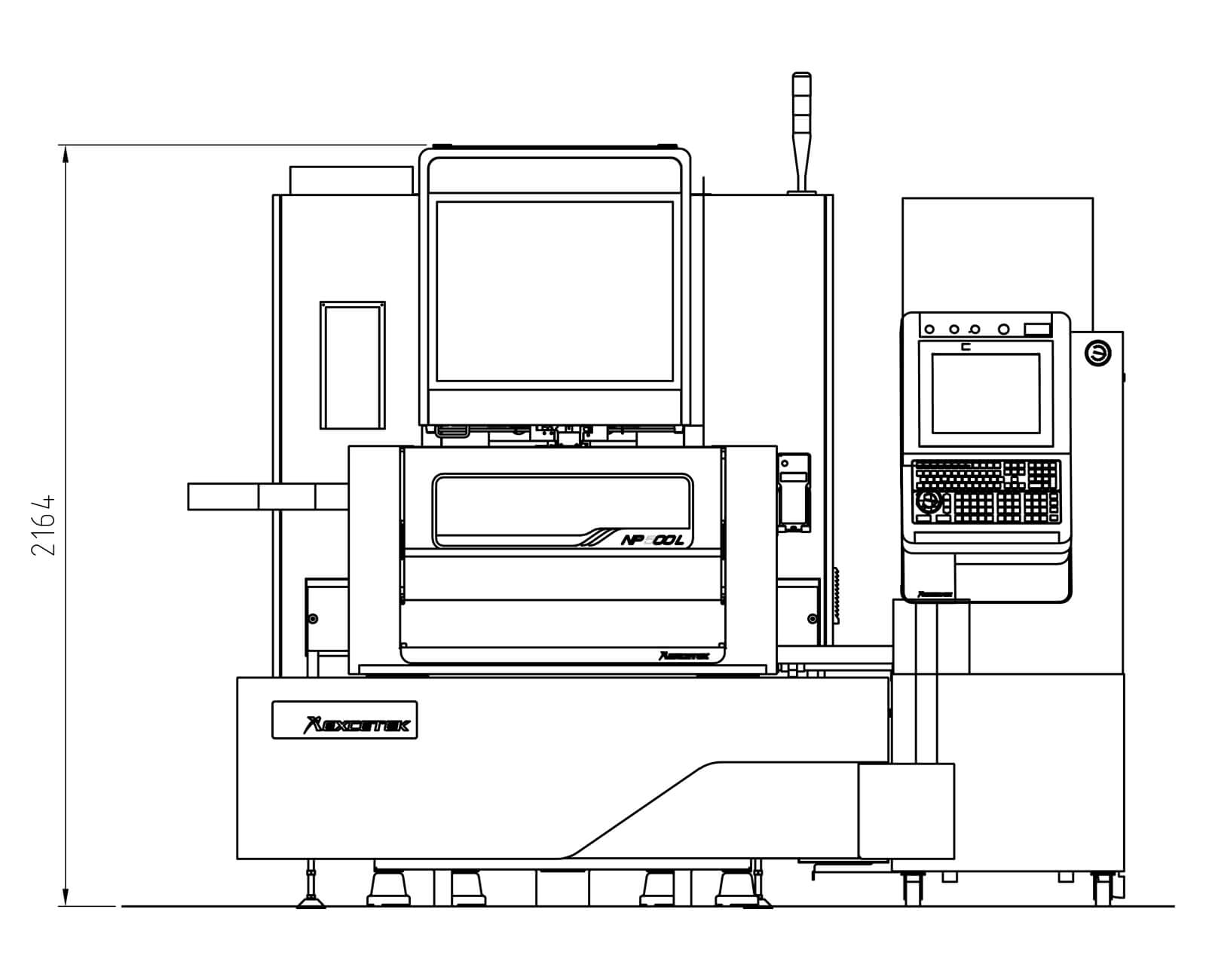

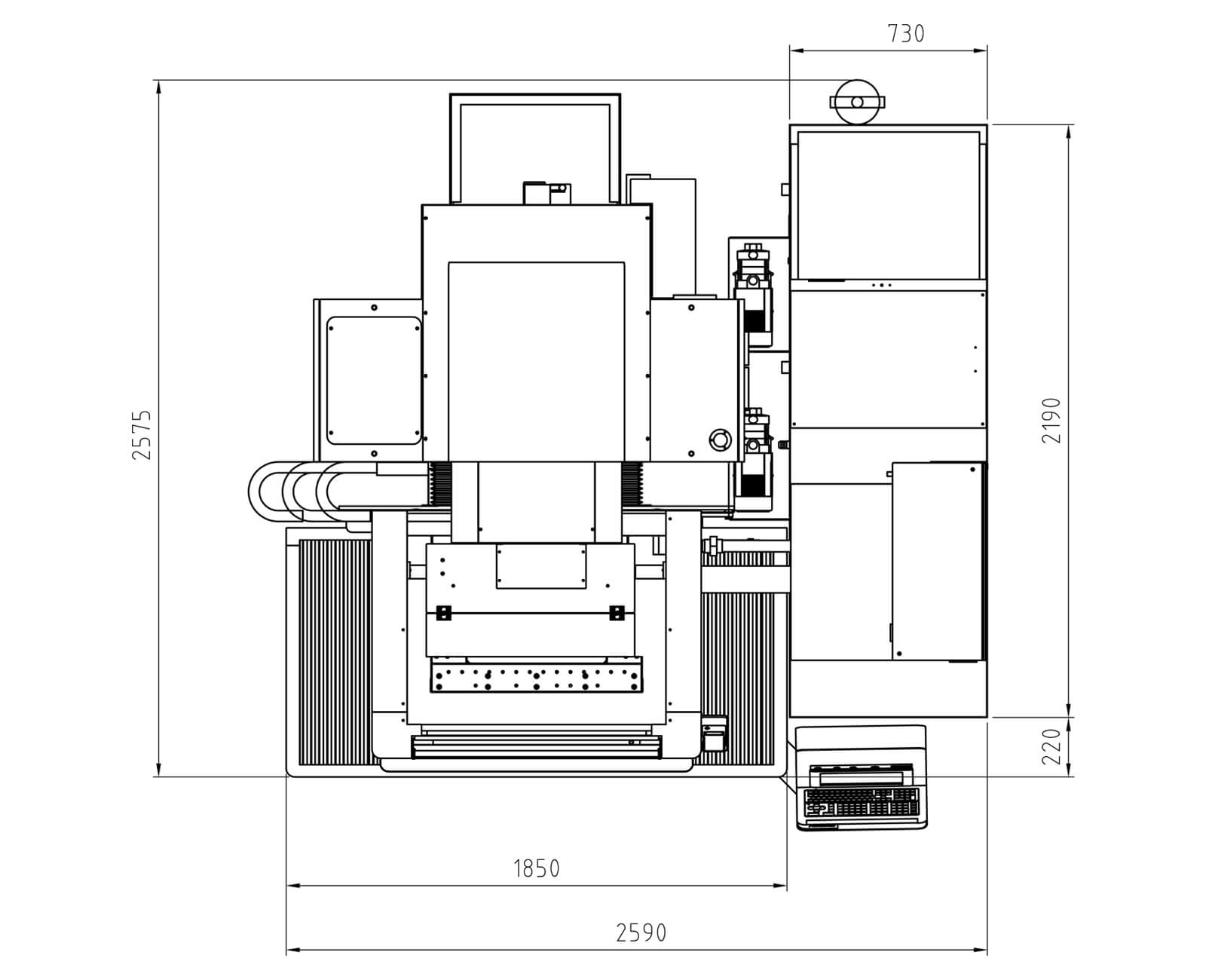

Machine dimensions: 2590 x 2575 x 2165 mm

Z axis travel: 310 mm

Machine weight: 3350 kg

Dielectric Tank

Tank capacity: 750 L

Deionzer: auto

Paper filter: 2 / pcs

Chiller unit: auto

Standard Accessories

- XY axis linear scale

- Brass wire x 1 spool

- AWT

- Clamping tool x 1 set

- Ion exchange resin x 10L

- Vertical alignment jig x 1 set

- Paper filter x 2 pcs

- Diamond guide x 2 pcs

- Upper and lower flushing nozzle x 2 sets

- Energizing plates x 2 pcs

Options

- Clamping Beam

- W-Axis

- AVR 15KVA

- Jumbo Feeder L-50A

- Transformer 15KVA

- Short Message Service (SMS)

- Signal Tower

- Remote Monitor System

- Auto measurement system

- Super Finish Circuit