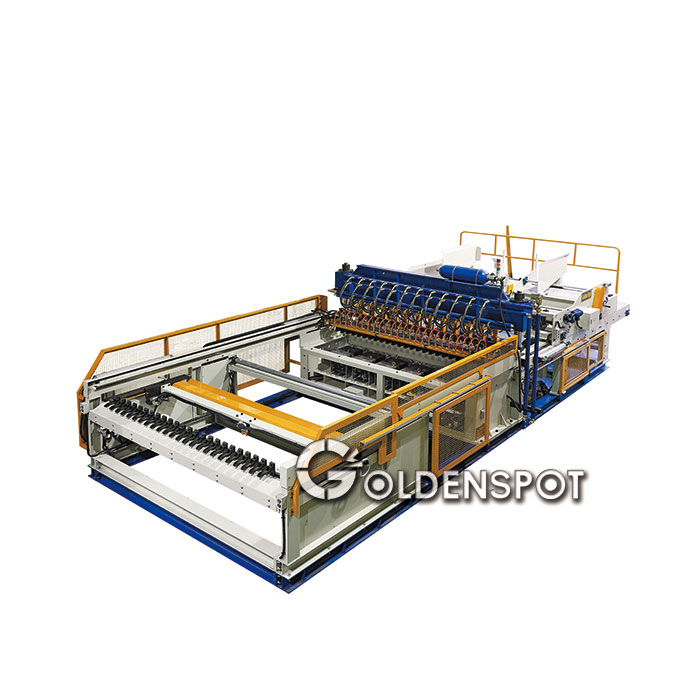

Products

• Single Spot.

• Feeding line wire to the spot welding position by manual.

• Press the workpiece by cylinder then fed by motor running.

• Reached to the spot welding system.

• Cross wire was fed by carriage with sole hopper.

• Feeding to the position then in the process of welding.

• Workpiece was holded by holding system.

• Wire mesh completed.

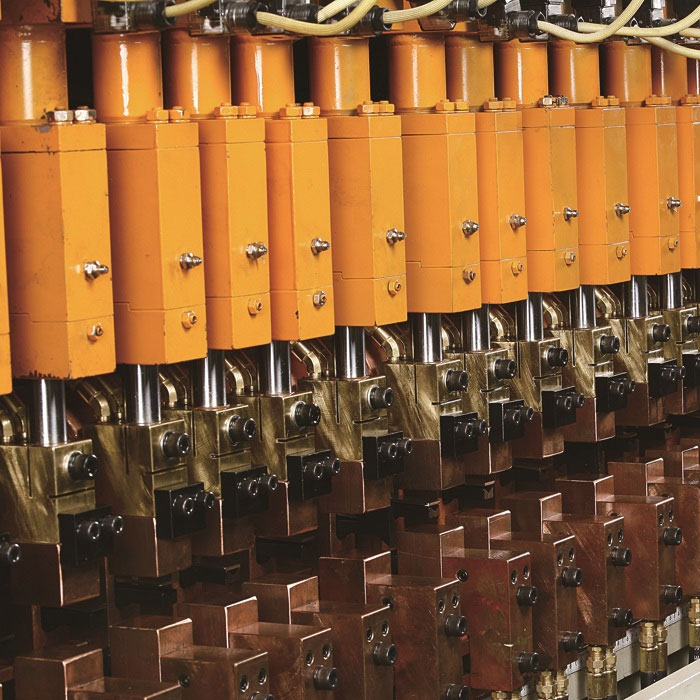

Spot Welding System

Adjusting the up compressed cylinder, electrodes, and fixture based on the wire pitch. Possible individually set welding time and current.

Single-point Welding

Cross Wire Feeding System

It is auto sole cross wire loading carriage. Carrying a bundle of wires into the carriage by traveler. Integrated with the welding system, it is with the function of auto wire ordering, outputting.

Output Installation

Equipped with servo motor and gripping pliers to adjust the required pitch, carry the welded mesh to next work station.

Controlling System

Equipped with man-machine interface windows based for the use of P.L.C, all the parameters and figures set on the screen. Easy for operators running and maintenance

Applications:

Shell structure, wall structure, reinforced concrete road, retaining wall, protection slope, floor, floor boards, successive wall, and so on.

Specification Table:

| Model | Line Wire Length mm | Cross Wire Length mm | Wire Diameter mm | Line Wire Pitch mm | Cross Wire Pitch mm |

|---|---|---|---|---|---|

| GSA-125S/2400 | 2000~6000 | 1000~2400 | 3~6 | ≧75 | ≧50 |

| GSA-200S/2400 | 2000~6000 | 1000~2400 | 6~12 | ≧75 | ≧50 |

| GSA-200S/3100 | 2000~6000 | 1000~3100 | 6~12 | ≧75 | ≧50 |

Related Products

- Wire Mesh Welding Machine (GSA-150L)

- Wire Mesh Welding Machine (GSA-200)

- Wire Mesh Welding Machine (GSA-125C)