Products

JAP100 Air Diaphragm Chuck

Product Features

◢ Air cylinder intergrated,no rotary cylinder and draw bar required

◢ Repeatability within 5 um

◢ Center through hole design,allow to set air blow or stopper in axis way

◢ Highly-sealed chuck body,helps protect cutting chips,dust or coolant fluid from entering

◢ Front-mount design make installation easy

◢ O.D/I.D clamping applies by only switch the jaw pad

◢ Gentle and Precise clamping,best for fragile and thin-wall work piece

◢ Please use 5um filter in F.R.L units

Introduction

JATO JAP100 Diaphragm chuck is putting effort in industry over 2 decades. Proudly design in our own structure and proof the ability with patens over Taiwan, China, Japan, German, and USA.

Diaphragm chuck is specialize to deal with the work piece as thin wall and fragile like aluminum and ceramic. Good performance in control the clamping force to prevent the object deformation.

JAP100 is built in rotary cylinder, which is free to use the draw bar and rotary cylinder behind the spindle. Even makes it much easier to install on the non-through hole spin unit, like the 4/5 axis table or servo spindle. Manual chuck and special thin rotary cylinder won’t be options when you have a rotary

chuck. All you need is a flange adaptor and air feeding, imaging a simple installation without specialist worker and anyone with technical common sense, can get installation done easily when all components ready.

Applications

◢ Spindle Grinding of DC Micro Motors

◢ Precise Bush

◢ Lens of Electronic Equipment

◢ Lens Frame of Smartphone

◢ Precision Sleeve

◢ Ceramics Grinding

◢ Cardiovascular stent

◢ Laser Carving, Laser Cutting, Laser W ielding

◢ Case of Stylus

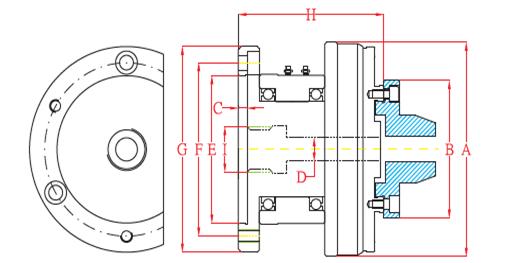

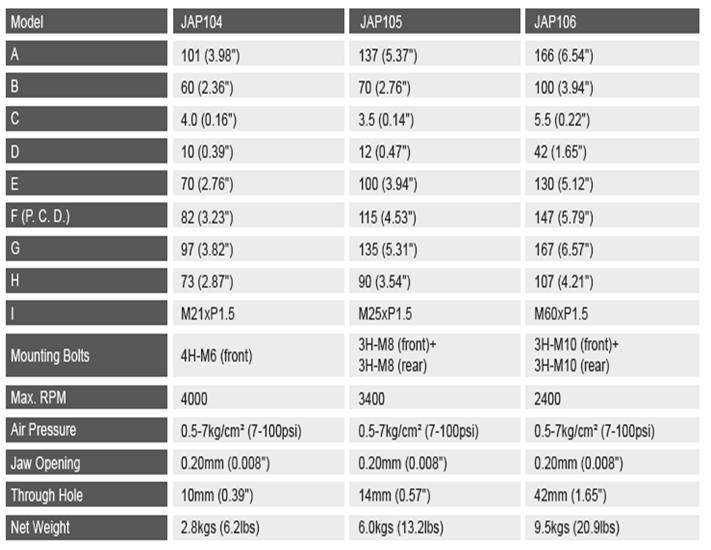

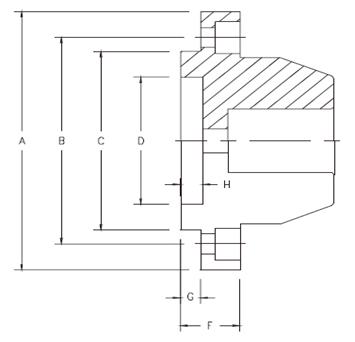

JAP100 Dimension and Specification