Products

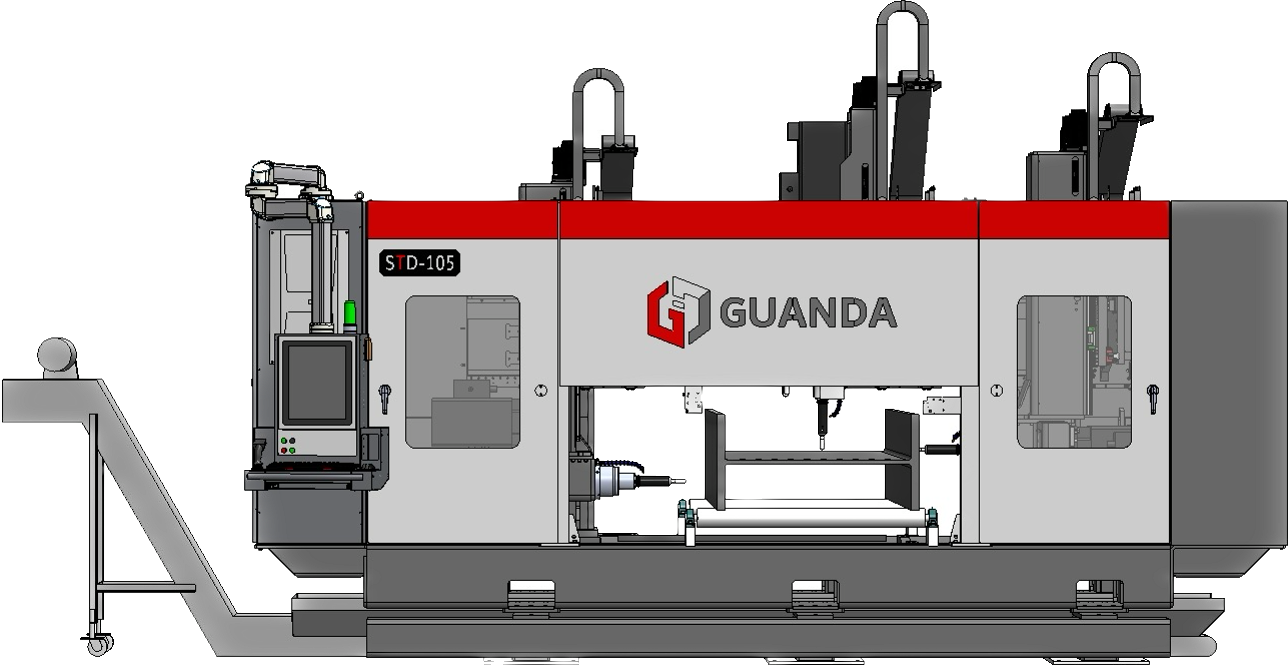

STD-105 10 Advantages

1

TEKLA cutting data can be imported directly to machine controller.

Not only TEKLA cutting data can be automatically transferred to CNC, but also included the relative data of cutting project.

2

Fully realize automatic components distribution.

Automatic 3D visualized components distribution

3

Fully Automatic machining operation

Automatically workpiece loading, feeding, drilling, tool changing, and exiting)

4

Applying with Tungsten drill bit

Feed-rate up to 9 mm/sec

5

MQL lubricant system

Effectively improve the lubrication effect and be friendly to the environment

6

Mobile App

Allowed remotely control and monitor during operation by moveable device.

7

19" multitouch screen available

The multi-touch screen supports various operations, and the multi-language interface makes the operation more friendly.

8

Exclusive patented technology

4 exclusive invention patents in the industry

9

User friendly operation interface

Operator education and training is simple and fast. Greatly reduces the cost of education and training.

10

MIT(Made in Taiwan), global high-quality service.

Guanda is the best partner in the structural steel processing industry.

Planning method for turning and processing steel building materials

patent

Drilling processing design method for steel building

Automatic Tool Changer at Left & Right Drill Spindles

Left and right drilling spindle can be flexibly equipped with automatic tool changer systems at both workpiece inlet or outlet positions. There are 4 tools per system at one position. Up to 8 tools system can be allowed to a drilling spindle. Tool change time is reduced effectively and processing efficiency is greatly improved. (ATC function can be performed by mobile APP.)

Automatic Tool Changer at Upper Drilling Spindle

An 5 tools ATC can be allowed to upper drilling spindle. Tool change time is reduced effectively and processing efficiency is greatly improved. (ATC function can be performed by mobile APP.)

Extra 300mm Auxiliary Travel on X-axis

Extra 300mm auxiliary X-axis travel on each drilling spindle, provide maximum flexibility of drilling position and improve the maximum efficiency of drilling.

Single CNC control unit

When adding various conveyor modular (such as shuttle conveyors, roller conveyors, and aligners), There is no need to add an additional CNC control unit.

MQL -Minimum Quantity Lubrication system

Oil mist through spindle offers low oil consumption, and high performance in drilling.

Hard alloy drill bit

Carbide tools achieve maximum spindle efficiency thanks to their high ability.