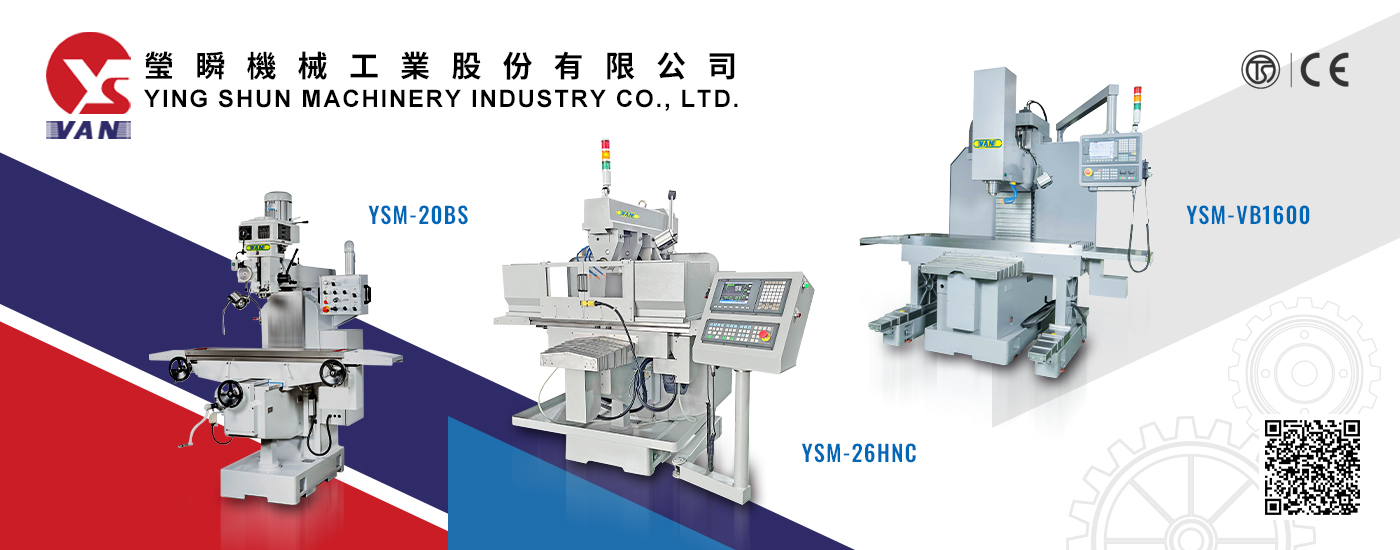

Electric Discharge MachineMachining CenterSpecial Purpose MachinePressing MachineMetal Forming Machine

Auto EngineAuto Engine SystemAuto Fueling SystemAuto Intake & Exhaust SystemAuto Lubrication SystemAuto Cooling SystemAuto AC SystemAuto ChassisAuto Transmission SystemAuto Steering SystemAuto Suspension SystemAuto Brake SystemAuto BodyAuto Body StampingAuto Wheel SystemAuto LampsAuto Exterior Trim

Auto Interior TrimAuto FastenerAuto Raw MaterialsAuto AccessoriesAuto ElectronicsAuto Electric & ElectronicWiper & WasherAuto CommunicationAuto Audio & VideoDriving Assistance SystemCar Navigation & GPSDrive RecorderAuto Safety & Security SystemAuto Electronics PartsConnector & Wire HarnessTire Pressure Monitoring SystemComplete Automobile/Commercial Car /Electric Vehicle

Sedan / RVCommercial Car & PartsElectric Powered Cars & PartsAuto Body BuildingTuning & RestylingSpecial Purpose Vehicles & PartsSpecial Purpose Vehicles & PartsMotorcycle/BicycleComplete MotorcycleMotorcycle EngineMotorcycle TransmissionMotorcycle Frame BodyMotorcycle BrakeMotorcycle SuspensionMotorcycle Electrical PartsMotorcycle WheelCustomized Bikes & Accessories

Motorcycle AccessoriesMotorcyclists` AccessoriesBicycle, Parts & AccessoriesMolds & Forming PartsMoldsPlastic & Rubber PartsMetal PartsRepair & MaintenanceRepair Tools & EquipmentMaintenance Equipment & ProductsMachinery & ServiceManufacturing EquipmentTesting EquipmentService