|

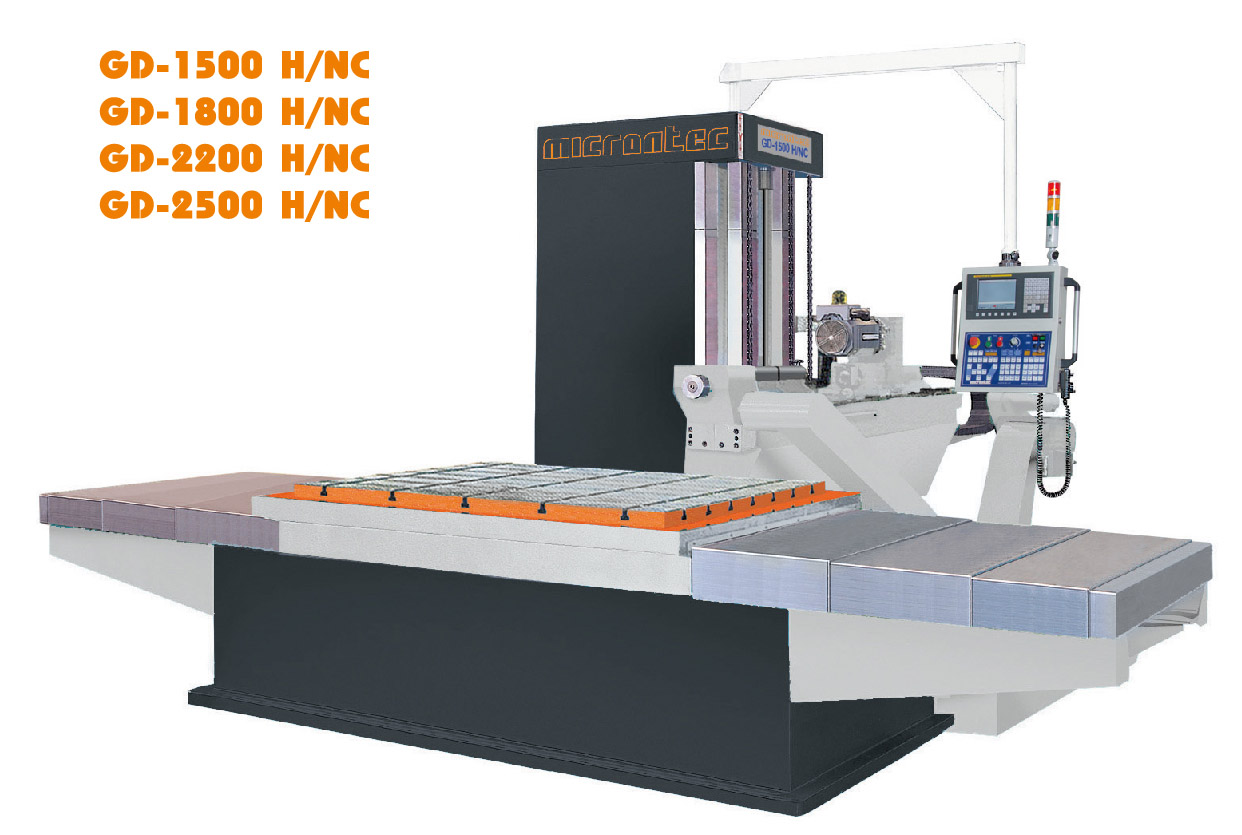

Model 機型

|

GD-2200H/NC

|

|

Working Range 加工範圍

|

|

Hole Dia. 鑽孔孔徑

|

Ø3~Ø32

|

|

Max. Depth 鑽孔最大深度

|

1450mm

|

|

worktable area 工作台面積

|

1200*2400mm

|

|

T-slots T型槽(寬*個*距)

|

22*08*300

|

|

Max. Loading capacity 工作台最大載重

|

15000kg

|

|

Travel 行程

|

|

Table (L/R) 工作台 左、右 (X asix X軸)

|

2200mm

|

|

Spindle Up/Down 主軸上下 (Y asix Y軸)

|

1200mm

|

|

Front/Rear Feeding 前後進刀 (Z axis Z軸)

|

1600mm

|

|

4th axis (A Axis) 輔助加工軸 (A axis 軸)

|

150 mm

|

|

Xaxis Ball screw for feeds X軸進給滾珠螺桿

|

Ø63 x P10 x C3

|

|

Y axis Ball screw for feeds Y軸進給滾珠螺桿

|

Ø50 x P10 x C3

|

|

Z axis Ball screw for feeds Z軸進給滾珠螺桿

|

Ø40 x P10 x C3

|

|

A axis Ball screw for feeds A軸進給滾珠螺桿

|

Ø40 x P10 x C3

|

|

Controller & Powers控制器&動力

|

|

Spindle Motor 主軸馬達

|

α6/5.5kw

|

AC Servo Spindle motor AC主軸系統5.5kw

|

|

Max. spindle speed主軸轉速

|

6000 rpm

|

|

X axis Motor X軸馬達

|

αc30/7.0

|

AC Servo AC伺服7.0kw

|

|

Y axis Motor Y軸馬達

|

αc22/3.0

|

AC Servo AC伺服3.5kw (with brake附煞車)

|

|

Z axis Motor Z軸馬達

|

αc12/1.8

|

AC Servo Spindle motor AC伺服2.0kw

|

|

A axis Motor A軸馬達

|

αc12/1.8

|

AC Servo AC伺服2.0kw

|

|

Controller System

控制器系統

|

發那科Fanuc

|

CNC 絕對系統

Absolute System

|

|

三菱Mitsubishi

|

|

其它Others Type

|

|

Controller System

控制器系統

|

Min. setting unit

最小設定單位

|

0.001 mm

|

|

Interface 介面

|

RS232

|

|

Drilling Feedrate Traverse 鑚孔進給速度

|

|

Drill Speed 鑽孔進給速度

|

1~ 200 mm / min

|

|

Special Drill Speed 特殊鑽孔進給速度

|

1~ 400 mm / min

|

|

Rapid Traverse 押送

|

|

Feeding Range 送料速度位移

|

1~5000mm/min

|

|

Rapid Traverse 快速押送位移

|

1~6000mm/min

|

|

Other Powers其他動力

|

|

High pressure motor 高壓切削油泵馬達

|

3.0 HP

|

|

High pressure pump capacity

高壓切削油泵

|

Pump output 流量輸出 19 Liter / min

|

|

Max. pressure 最大壓力 100kg/c㎡

|

|

Coolant tank 油箱容量 1200 Liter

|

|

Low pressure motor 低壓切削油泵馬達

|

7.5 HP

|

|

Low pressure pump capacity

低壓切削油泵

|

Pump output 流量輸出 61 Liter / min

|

|

Max. pressure 最大壓力 15~40kg/c㎡

|

|

Coolant tank 油箱容量 1200 Liter

|

|

Oil cooler cooling capacity 油冷卻機冷卻能力

|

7500~9000kcal/hr

|

|

Chip converyor motor 排屑機馬達

|

0.2kw

|

|

Cutting oil percolation motor 切削油過濾馬達

|

3/4HP

|

|

Machine Packing List 機械裝箱明細

|

|

Machine dimensions 機械尺寸

|

5500*6000*3450

|

|

Floor space 佔地面積

|

5500 x 6000 mm

|

|

Machine Net weight 機械淨重

|

20000kg

|

|

Accessories 附件

|

|

Standard accessories 標準附件

|

1.High pressure coolant pump

高壓切削油泵

|

|

2.Automatic lubricator 自動注油器

|

|

3.Chip conveyor 鐵屑輸送機

|

|

4.Tool box with tools 工具箱

|

|

Optional accessories 特別附件

|

1.Magnetic separator + Paper filter unit

鐵屑分離機+紙帶過濾機

|

|

2.Coolant cooler 切削油冷凍機

|

|

3.Gundrill grinder 槍鑽研磨機

|

|

4. 4th axis rotary table

回轉式工作台(4th軸)

|

|

5.Auxiliary Milling & Tapping Head

[BT-40]

第二副主軸-銑床及攻牙

|

|

6.All-enclosed splash guard

全罩式鈑金

|

|

7. CE Certificate CE認證

|