2021-12-14

How to choose an EDM manufacturer?

What is an EDM machine?

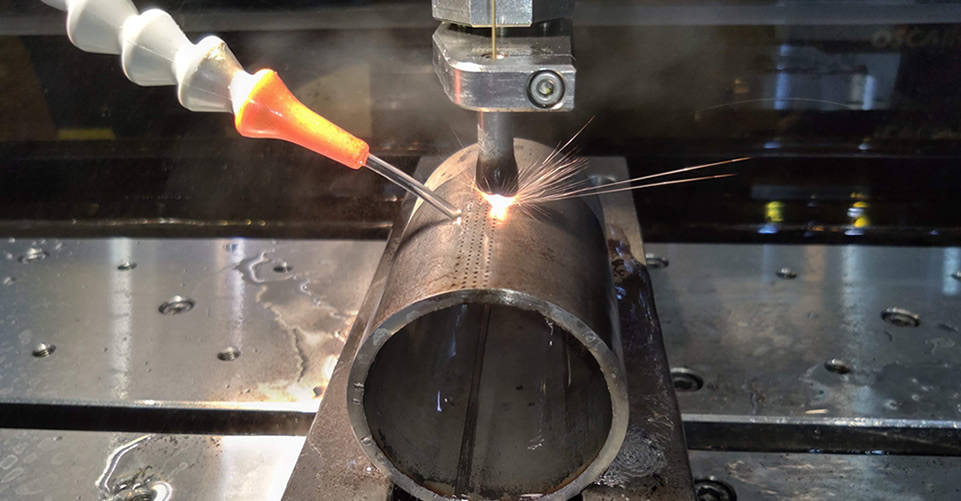

The method of choice is when great accuracy is required beyond the capability of other machining technologies, EDM, or electric discharge machining. It does not utilize force to remove and shape the material.

Wires that discharge electricity to cut through the workpiece material are used instead. Thermal energy is used in the EDM process to meet the machining needs. Its lack of mechanical force earns it the moniker of "non-conventional machining."

The materials used to make EDM electrodes must have the dual and slightly paradoxical traits of permitting rapid charge flow while resisting the eroding characteristics. In other words, while the electrical discharges must destroy the workpiece, the electrode should not. Several metallic alloys have particularly well-suited characteristics to specific EDM applications.

Sinker EDM machines of the CMAX S1470 type are advanced CNC. It has motion machining in 3D mode. Up to 2080 liters of oil may be stored in the tank. The machine's body is composed of cast iron and can withstand loads of 6000 kg. It may also be linked to a robot hand, allowing it to alter the electrodes.

How to choose an EDM manufacturer?

Of course, you have unique issues about your electrical discharge machining (EDM) provider that other businesses don't have to think about. When looking for an EDM manufacturer, keep the following suggestions in mind:

Is sinker or wire EDM used?

If you have a preference, you should always confirm the type of EDM system your potential EDM manufacturer utilizes. Sinker and wire EDMs are the most frequent, even though there are additional alternatives.

Sinkers function by immersing electrodes and the workpiece in a liquid. The electrical potential needed to create the sparks is then generated by connecting a power supply. To cut a bigger metal component and make a precise incision, wire EDMs will only utilize one string of thin metal wire.

Most industries looking for EDM won't care whether the approach is employed. However, if your EDM manufacturer does, you should always double-check that a possible provider employs that strategy.

How do they set up their machines?

You should consider how the tools given by the EDM manufacturer will fit into your workflow, regardless of the sort of gear you're looking for. Ascertain that staff can maneuver around the machinery and compatible with other equipment.

It's just as crucial to know your area as it is to know how long it will take to set up and carry the gadget. These aspects will be influenced by the way you set up your equipment. You should also ask if the supplier has fittings that allow stacked and worked on simultaneously.

Alternatively, you may seek an EDM manufacturer with equipment set up so that numerous EDM procedures can be performed simultaneously, even on the same piece.

It would also be beneficial to discover an EDM manufacturer that can assist you in picking a machine and providing basic instructions, just like any other machinery.

Customer feedback:

You should also think about what other EDM manufacturers use to offer solutions. Reading credible evaluations from respectable sources is one approach to achieve this.

Customer evaluations from people who have used the EDM manufacturer firsthand might give you a better sense of what to anticipate. A company's reputation and degree of experience speak louder than any advertisement in the business world.