2021-12-14

All About the EDM Drilling Machine

EDM drilling machines are machine tools mainly use to drive fasteners or make small holes. An EDM drilling machine also comes in handy for the process of drilling. This is the processing technology that is usually used in manufacturing production.

How EDM Drilling Machines Work

An EDM drilling machine works similar to other processes that use EDM. However, the most notable difference is the fact that EDM drilling machines have been optimized to produce semi-accurate tiny holes in the ductile materials in high speeds despite the hardness of the material.

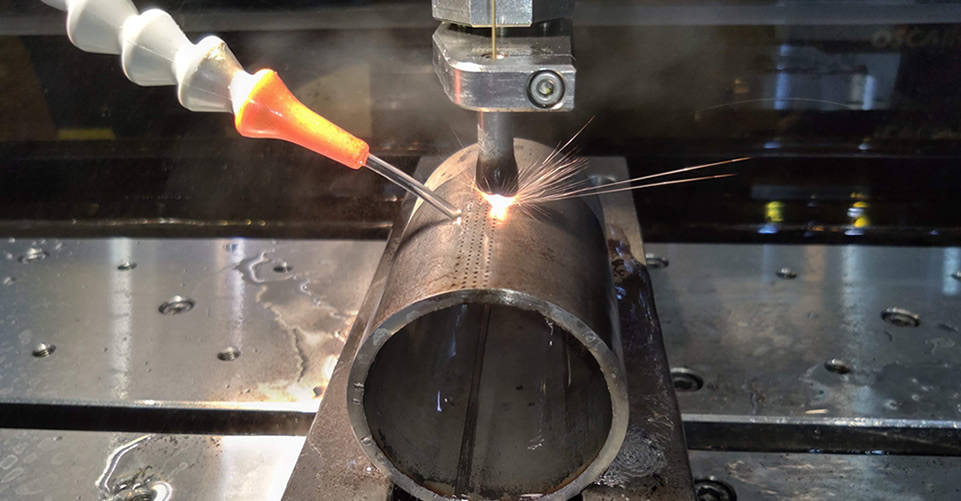

During the operation of an EDM drilling machine, the material will be removed from the specific work object through a series of current discharges that quickly recur between the two electrodes, with a dielectric fluid separating them, and subjected to the electric voltage.

The first electrode is called the tool electrode or just referred to as the electrode or tool, while the second one is known as the workpiece electrode, also simply called as work piece. The whole process of EDM is dependent on the absence of physical contact between the tool and the work piece.

In the process of EDM hole drilling, electrode particles are washed away from the cut by the dielectric, with the flushing liquid required to get delivered to the lowest portion of the hole that is being cut for this to be achieved. Here, there is a need to use a drilling electrode with a tube that allows easy and consistent passing of the fluid through the electrode.

EDM Drilling Machine Applications

There are different applications where EDM hole drilling comes in handy. For one, EDM drilling machines are used for drilling rows of tiny holes into the trailing and leading edges alike of the turbine blades that are utilized in jet engines.

The gas flows through these tiny rows of holes to allow the engines to use high temperatures. High temperature, single and hard crystals get deployed into the blades to allow conventional machining of the holes with high aspect ratio very hard, if possible.

The EDM drilling machines are also used to form microscopic orifices for the components of fuel systems, spinnerets for synthetic fibers such as rayon, as well as other applications. There are also standalone models featuring X and Y axes that can machine through or blind holes, or often called super drill.

An EDM drilling machine can drill bore holes with long copper tube electrode rotating in a chuck with consistent flow of deionized water that flows through the electrode as the flushing or dielectric agent. These have the capacity to drill through 100mm of hard steel in less than 10 seconds, with an average wear rate of 50% to 80%. This drilling operation also makes it possible to achieve holes as tiny as 0.3mm.

Even though it is easier to machine brass electrodes, these are usually not recommended for the wire cut operations because of the eroded brass particulars that can cause wire breakage.