Products

Coatings applied in cutting tools have been proved to be very effective. There are several objectives that coatings must achieved.

The objectives are to:

Cut costs

Enhance productivity

Increase manufacturing reliability

To attain these objectives, the focus must be on tools which fulfill ever more stringent requirements. A key role is played by the coating which interacts with the base material and the tool geometry to achieve superior performance. Princo's coatings can sufficiently increase the service life of tools several times than non-coated tools, often with a concurrent improvement of cutting data. They offer reproducible process behavior at a high performance level.

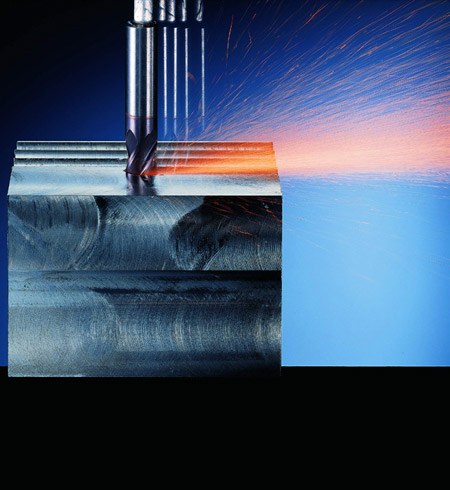

Tool

Tool

Solid carbide rougher, diam, 10mm, 25/64, 3 edges

Workpiece

Construction steel

1.2311 /40 CrMnMo 7

P20

Rm = 1050 N/mm2 33 HRc

Cutting parameters

n = 3180 rpm;

vc=100m/min, 328.1 sfm;

ft = 0.035 mm, 0.0014 ipt;

ae =3mm, 0.0117inch;

ap =16mm, 0.624inch;

coolant: 5% emulsion;

Source

Balzers

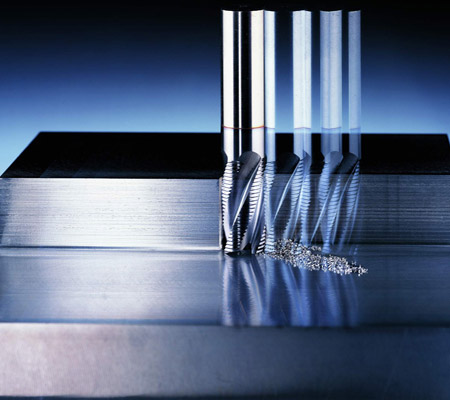

Tool

Solid carbide ball mill,

diam, 12mm (0.472")

4 edges

Workpiece

DIN 1.2311 (40 CrMnMo 7)

AISI P20

Cutting parameters

n=11000rpm;

vc=410m/min (1345 sfm)

f =8m/min (26.2 sfm)

doc=0.2 mm

no coolant

Source

Balzers