Products

◆ Specification:Die Size 65 x 100 mm

◆ T-SOK Multi-Slide Die Casting Machines Your energy-efficient quiet and clean production solution for the future.

◆ Fully electric operation Eco-Friendly & Energy-Saving

◆ Less manual control USer-Friendly design

◆ Electric control combination equipment, lower maintenance cost Easy maintenance

◆ Clean technology Good working environment

◆ Similar closed-loop system design is usde to eliminate the "Hammer Effect" and minimize burrs High precision and stable quality

T-SOK Electric Multi-slide-Technology

- A conventional hot chamber die casting tool is usually made of two die halves: a fixed die half and an ejector die half. When the die casting machine clamps together, the two die halves are locked and held together by the machine’s hydraulic pressure. The surface where the ejector and fixed halves of the die meet and lock is referred to as the die parting line. Once the dies are clamped together, an injection process takes place in the fixed die half.

- The cavity is fed through a sprue and runner system. This cavity is filled with liquid metal each time a shot is made. It is common practice to add overflows to vent the tool to avoid trapping air during the injection process.

- Although this conventional die casting technology has become one of the dominant methods people make parts. It still has its drawbacks. The ratio of part weight to scrap weight is too high, the tooling is expensive, and its high energy consumption rate, are all examples of this conventional technology’s disadvantage.

- The T-SOK’s electric multi-slide hot chamber die casting helps solve these problems. Instead of using two die halves, T-SOK electric multi slide die casting machines consists of two to six slides all moving independently, and each with its own die blocks. When the die casting machine closes, the die blocks from a complete cavity to inject the material.

- Instead of feeding the cavity through a sprue and runner system, it is directly injected through the parting line, thus eliminating the need of the sprue. Evolutionary multi slide design, mold design diversity, wide selection of mold parting directions (two to six directions), the core can be removed from any angle and direction. High mold precision, suitable for high precision and high complexity parts production, up to 40 shots per minute, and easy die change over in 20 minutes.

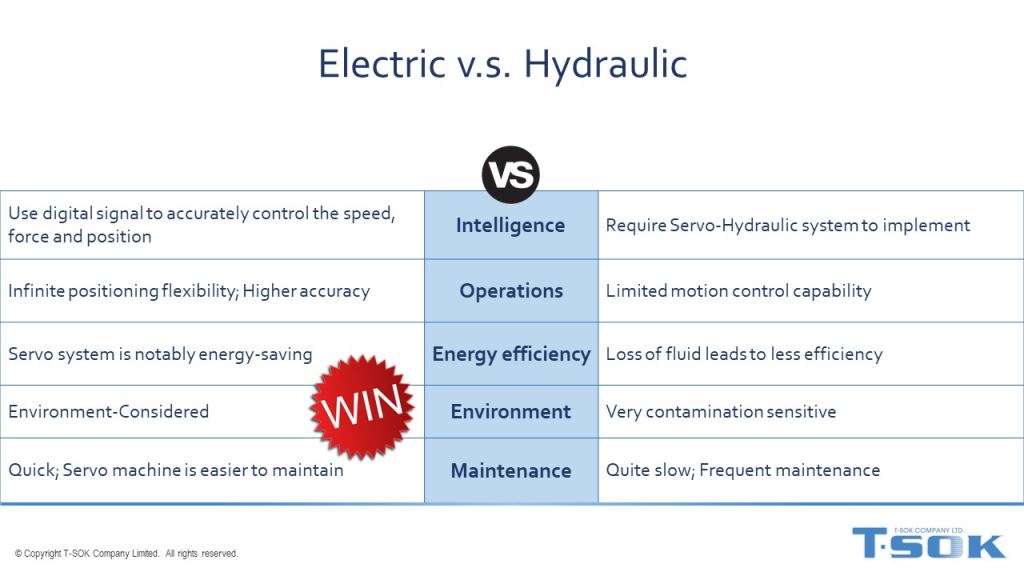

Electric & Hydraulic

- Eco-Friendly & Energy-Saving

The electric energy is directly converted into kinetic energy. Energy consumption reduces 50-70%. There’s no necessary hydraulic oil cooling system.

- Good workplace environment

Reduce operating noise. No messy leaks. No fire risk and contamination issues.

- Easy maintenance and safety

Fewer components, less maintenance, and lower production waste. Servo motors run independently with every axis, much easier to troubleshoot and repair.

- User-Friendly design

Simplified installation and control. Less manual control. Easier to control by touch panel.

- Stable quality and density

Precise control of speed, force and position. Eliminate the “Hammer Effect” and minimize burrs. Good parts density.