Products

BT40

X810 / Y520 / Z520

FEATURES

Belt type spindle:10,000 RPM

Direct drive spindle:10,000 / 12,000 RPM

Arm type 24 tools ATC

Rapid feedrate:36 M/min

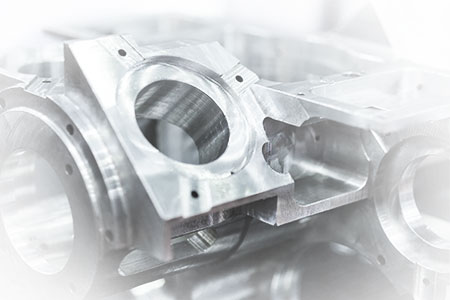

The base structure is reinforced by internal ribbing to ensure high rigidity and stability.

The machine processing fast, high precision, three axes rapid feedrate 36 m/min, it is safe time to achieve economic efficency.

Applicable Industries:3C industries, Communications industry, Molds, Automotive and motorcycle parts.

The ATC of supporting seat and column are one-piece. It is stability when tool change tool.

Workpiece

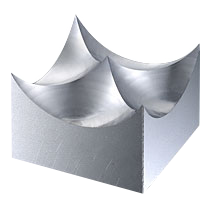

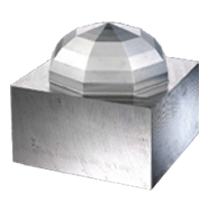

Spiral

Deep needle

Lampshade

APPLICATION

SPECIFICATIONS

| Model | MT-850 V | MT-850 VS | ||||

|---|---|---|---|---|---|---|

| Table | Size | mm | 900 x 500 | 900 x 500 | ||

| T-slot (width x no x distance) | mm x T | 18 x 5 x 90 | 18 x 5 x 90 | |||

| Maximun table load | kgs | 500 | 500 | |||

| Travel | X, Y, Z -axis | mm | 810 x 520 x 520 | 810 x 520 x 520 | ||

| Table top surface to spindle nose | mm | 90-610 | 90-610 | |||

| Distance between spindle center and column surface |

mm | 580 | 580 | |||

| X, Y, Z-Axis linear guideway type | mm | 35 / 35 / 35 | 35 / 35 / 35 | |||

| X / Y / Z-Axis Ball screw | 40 / 40 / 40 | 40 / 40 / 40 | ||||

| Spindle | Spindle holder | BELT | DIRECT | |||

| Taper | BT40 | BT40 | ||||

| Diameter | mm | ∅70 | ∅70 | |||

| Spindle speed | rpm | 10000 | 10000 | |||

| Feed | Three axes | Roller type linear guideway | Roller type linear guideway | |||

| Cutting feedrate X / Y/ Z (G01) | m/min | 10 / 10 / 10 | 10 / 10 / 10 | |||

| Rapid feedrate X / Y / Z (G0) | m/min | 36 / 36 / 36 | 36 / 36 / 36 | |||

| ATC | Type | ARM | ARM | |||

| Max. tool Dia | mm | ∅75 / ∅150 | ∅75 / ∅150 | |||

| Max. tool length | mm | 300 | 300 | |||

| Max. tool weight | kgs | 7 | 7 | |||

| Tool type | BT40 | BT40 | ||||

| Tool magazine capacity | T | 24 | 24 | |||

| Motors | Spindle (Cont. /30 min) | kw | 7.5 / 11 | 7.5 / 11 | ||

| X / Y / Z -Axis | kw | 2.0 / 2.0 / 3.0 (Mitsubishi) 3.0 / 3.0 / 4.0 (FANUC) |

2.0 / 2.0 / 3.0 (Mitsubishi) 3.0 / 3.0 / 4.0 (FANUC) |

|||

| Coolant pump | kw | 0.75 | 0.75 | |||

| ATC motor | w | 350 | 350 | |||

| Air conditioner | w | 500 | 500 | |||

| Spindle oil cooler | w | 600 | 600 | |||

| Chip flush motor | w | 2580 | 2580 | |||

| Other | Machine space ( L x W ) | mm | 2200 x 2050 | 2200 x 2050 | ||

| Splash guard | Full-closed splash guard | Full-closed splash guard | ||||

| Coolant tank capacity | L | 250 | 250 | |||

| Net weight | kgs | 5300 | 5300 | |||

| Total power consumption | kw | 20 | 20 | |||

* All specification , dimension and design characteristics shown in this catalogue are subject to change without notice.

- STANDARD ACCESSORIES

- Full-closed splash guard

- X, Y, Z-Axis telescoplc guideway cover

- Oil skimmer system

- Water gun and air gun

- Chips flush system

- Tools box

- LED work lamp

- Arm type 24 tools ATC

- Automatic lubrication system

- Heat exchanger for electric cabinet

- 3 color Alarm light

- MITSUBISHI controller M80

- Screw type chip conveyer

- Automatic tool length measuring device

- Spindle oil cooler system

- Spindle splash ring

- OPTIONAL ACCESSORIES

- FANUC system controller

- SIEMENS system controller

- Direct type spindle 12,000 / 15,000 RPM

- Built type spindle 20,000 / 24,000 RPM

- Coolant through spindle

- Air conditioner

- Transformer

- Voltage regulator

- Flat type chip conveyer

- CE norm

- 3-Axes optical scale

- Breakage detection system

- Oil mist collector

- Inverter ATC system

- X and Y Axis coolant through ball screws

- CNC 4th Axis rotary table

- CNC 4th & 5th Axis rotary table