Products

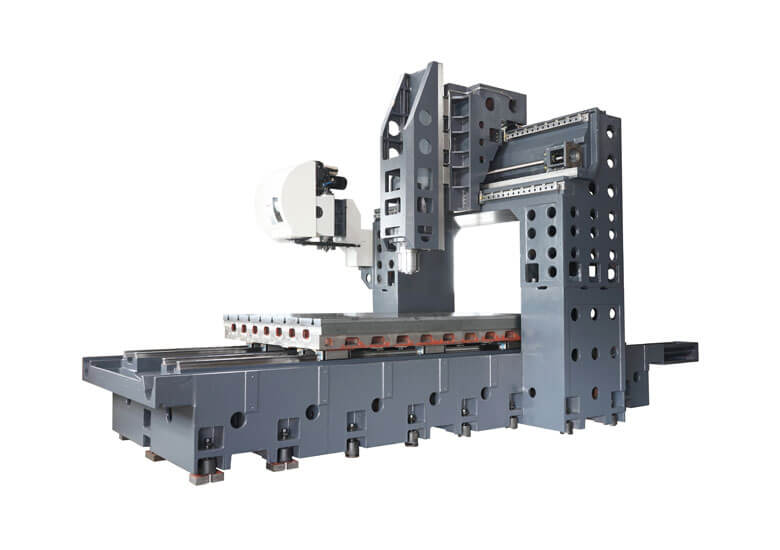

BBT40

X1450 / Y1650 / Z700

FEATURES

The pendant control box can be arbitrarily rotating swiveling. The user can set the spindle tool on machine side easily.

The major parts are manufactured from cast iron, strong structure and strong ability to with stand shock.

The entire machine structure has been analyzed and designed by SOLIDWORKS for superior rigidity and accuracy.

Three-Axes roller type linear quideway, improve the cutting load to ensure dynamic accuracy and long service life.

Linear way of Ladder type beam construction on Y axis. Extra wide span between two linear ways exhibits outstanding stability of cutting.

Six roller type slide blocks on Z axis, to ensure that the spindle accuracy and stable when machining cutting.

Robust Structure

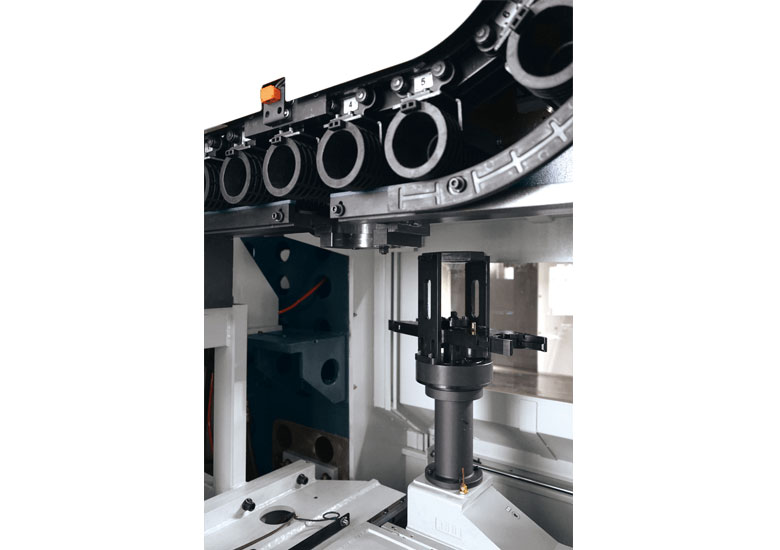

Change Tool Type ( OPT. BT50 / 32T )

Flat Type Chip Converyer

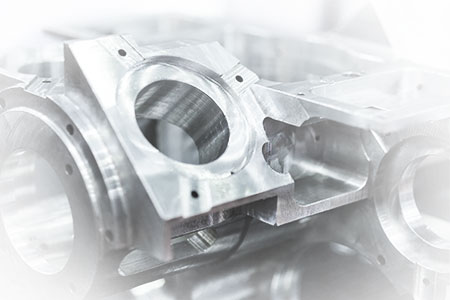

APPLICATION

SPECIFICATIONS

| Model | MT-5765 VD | MT-5765 VSD | ||

|---|---|---|---|---|

| Table | Size | mm | 1550 x 1450 | 1550 x 1450 |

| T-slot (width x no x distance) | mm x T | 20 x 8 x 180 | 20 x 8 x 180 | |

| Maximun table load | kgs | 3800 | 3800 | |

| Travel | X, Y, Z-axis | mm | 1450 x 1650 x 700 | 1450 x 1650 x 700 |

| Table top surface to spindle nose | mm | 134-834 | 134-834 | |

| Spindle center to column slide ways | mm | -- | -- | |

| X, Y, Z-Axis linear guideway type | mm | 45 x 4/ 45 x 2, 35 x 1/ 45 x 2 | 45 x 4/ 45 x 2, 35 x 1/ 45 x 2 | |

| X / Y / Z-Axis Ball screw | 63 / 45 / 40 | 63 / 45 / 40 | ||

| Spindle | Spindle holder | DIRECT | BUILT | |

| Taper | BBT40 | BBT40 | ||

| Diameter | mm | ∅70 / OPT. ∅90 | ∅65 | |

| Spindle speed | rpm | 15000 | 20000 | |

| Feed | Three axes | Roller type linear guideway | Roller type linear guideway | |

| Cutting feedrate X / Y / Z (G01) | m/min | 10 / 10 / 10 | 10 / 10 / 1 0 | |

| Rapid feedrate X / Y / Z (G0) | m/min | 20 / 20 / 20 | 20 / 20 / 20 | |

| ATC | Type | ARM | Umbrella | |

| Max. tool Dia | mm | ∅75 / ∅150 | ∅75 / ∅150 | |

| Max. tool length | mm | 300 | 300 | |

| Max. tool weight | kgs | 7 | 7 | |

| Tool type | CAT40 | CAT40 | ||

| Tool magazine capacity | T | 24 | 12 | |

| Motors | Spindle | kw | 15 | 23 |

| X / Y / Z-Axis | kw | 7.0 / 7.0 / 7.0 | 7.0 / 7.0 / 7.0 | |

| Coolant pump | kw | 0.75 | 0.75 | |

| ATC motor | w | 1650 | 1650 | |

| Air conditioner | w | 500 | 500 | |

| Spindle oil cooler | w | 600 | 600 | |

| Chip flush motor | w | 1290 | 1290 | |

| Other | Machine space ( L x W ) | mm | 4880 x 3772 | 4880 x 3772 |

| Coolant tank capacity | L | 500 | 500 | |

| Net weight | kgs | 15400 | 15400 | |

| Total power consumption | KVA | 50 | 50 | |

| Air source required | kg/cm2 | 7 up | 7 up | |

* All specification , dimension and design characteristics shown in this catalogue are subject to change without notice.

- STANDARD ACCESSORIES

- Full-closed splash guard

- Oil skimmer system

- Water gun and air gun

- Chips flush system

- Tools box

- LED work lamp

- Automatic lubrication system

- Heat exchanger for electric cabinet

- 3 color Alarm light

- Automatic tool length measuring device

- Spindle oil cooler system

- Spindle splash ring

- Screw type chip conveyer

- OPTIONAL ACCESSORIES

- BBT #40 Direct type spindle 12000 RPM

- BBT #50 Direct type spindle 6000-8000 RPM

- HSKA63 Built type spindle 24000 RPM

- Long type spindle

- Flat type chip conveyer

- Coolant through spindle

- 3-Axes optical scale

- CE norm

- Breakage detection system

- Oil mist collector

- Inverter ATC system

- X and Y Axis coolant through ball screws

- CNC 4th Axis rotary table

- CNC 4th & 5th Axis rotary table