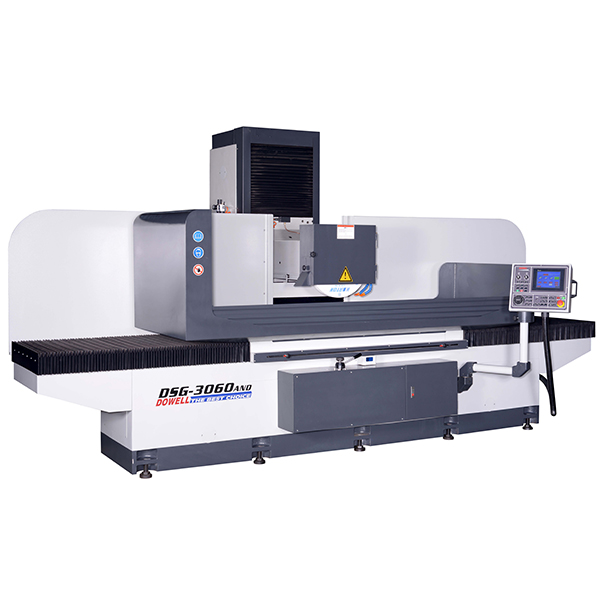

Products

Machine structure is manufactured from high quality Meehanite class FC cast iron

Spindle motor select high stability Siemens motor

X and Z axis guide way use double V design

The large spindle use CP6 precision angular contact ball bearing (Front 4 and Rear 2) ensure heavy grinding ability.

Y and Z axis use precision ball screw

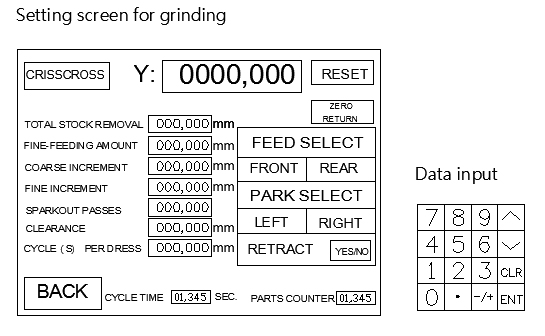

Y axis use AC servo motor and go with MPG reach high feeding accuracy

Cross stroke adjusting function get rid of inconvenience of traditional sensor and increase grinding efficiency. All guide way and ball screw use automatic lubrication system for forced cycle lubrication (with alarm for oil detective)

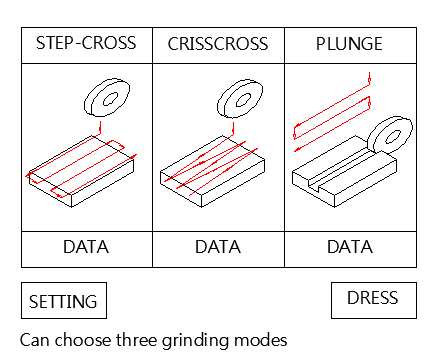

AND control: The operation modes are easy and simple for user to set up auto grinding.

AND:PLC automatic in 3 axes(x,y,z)

AND control

-

-

-

-

DESCRIPTION UNIT DSG-3060AND General Capacity Table size (lxw) mm 750x1500 Max.grinding length mm 1500 Max.grinding width mm 750 Standard mag. Chuck size mm 750x1500 Hydraulic traverse mm 1600 Hydraulic feed (table speed) approx. m/min 3~25 Cross Movement Manual travel mm 800 Auto cross feed mm 800 Hand feed per revolution mm/MPG 0.1mm/MPG Hand feed per graduation mm/MPG 0.001mm/MPG Continuous cross feed (approx.)50/60HZ mm/min 1000 Increment cross feed mm/min 1~20 Vertical Downfeed Rapid traverse (approx.) mm/min 1000 Hand feed per revolution mm/MPG 0.1mm/MPG Hand feed per graduation mm/MPG 0.001mm/MPG Auto downfeed rate mm 0.001~0.099 Jog mm 0.001 Pre-set spark out times 0.9(passes) Manual pulse generator x1, x5, x10 Grinding Wheel Wheel size (diax width xbore) mm Ø510x50x203 Spindle speed (50/60HZ) r.p.m 1450/1750 Motor Spindle drive motor HP 15 Hydraulic motor HP 7.5 Cross feed motor W 500W (AC SERVO) Rapid hand elevatipn servo motor KW 1 Weight Net weight / gross weight (approx.) kg 9500/10500 Packing Size Length × width × height mm 4950x2500x2990 ※ The manufacturer reserves right to modify the design,specification mechanisms etc. without notice.

STANDARD ACCESSORIES

- Grinding wheel

- Wheel flange with extractor

- Balancing arbor

- Diamond dresser and base

- Working lamp

- Leveling plate

- Leveling screw & nut

- Tool box with tools

- Operation manual & Inspection report

- Touch-up paint