Products

Meehanite Class FC30 casting with slide way provides high stiffness and wear resistance maintaining the accuracy of the machine.

Vertical Y axis uses Class 1 ball screw Ø50 provides high stability during feeding.

Vertical and longitudinal feeding uses high stiffness and rigidity linear roller guides made in Japan (slide block x6) provides smooth feeding but still maintain high stiffness.

Vertical spindle Y axis uses peumatic counterweigh to reduce ball screw and servo motor loading to make movement more smoothly and extend the use of life.

Horizontal Spindle uses six high precision ball bearing for heavy grinding.

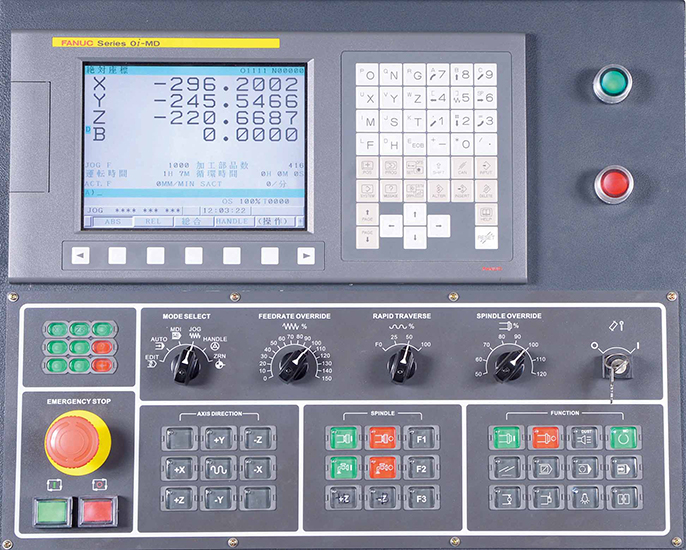

Control system

-

MITSUBISH (STD.)

-

FANUC / (OPT.)

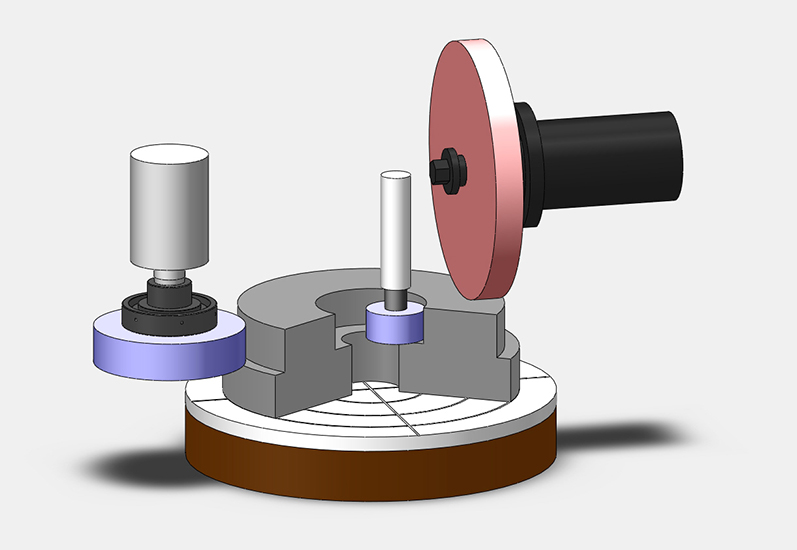

Schematic View

-

-

DESCRIPTION UNIT VHR-600 Table size mm Ø600 Processing travel-vertical spindle Grinding inside diameter - Ø60~Ø550 Grinding outside diameter - Max. Ø600 Table maxi grinding radius (horizontal spindle) mm 325 Distance of table surface to spindle surface top (vertical spindle) mm 380 Distance of table surface to spindle surface center (horizontal spindle) mm 500 Table load kg 280 Table speed r.p.m 25~150 Workpiece grinding height (vertical spindle) mm Max. 300 Workpiece grinding height (horizontal spindle) mm Max. 350 Horizontal spindle horse power KW/HP 7.5/10 Vertical spindle horse power (inside diameter) KW/HP 2.2/3 Vertical spindle horse power (outside diameter) KW/HP 3.7/5 Horizontal spindle speed 50/60Hz r.p.m 1450/1750 Vertical spindle speed (inside diameter) r.p.m Max. 8500 Vertical spindle speed (outside diameter) r.p.m Max. 4200 Wheel size Horizontal axis : dia x width x bore mm Std.Ø355x38x127

Opt. Ø405x50x127Vertical inside diameter : dia x high mm Min.Ø65x30

Max. Ø110x30Vertical outside diameter : dia x high mm Max. Ø205x50 Net weight/gross weight (approx) kg 14000/15500 Packing size (LxWxH) mm 5500x2300x3700 ※ The manufacturer reserves right to modify the design,specification mechanisms etc. without notice.