Products

Properties

Cold work tool steel with excellent air hardening properties, good dimensional stability, good toughness, high compression strength and wear resistance.

Very good retention of hardness, excellent electrical discharge machining properties.

Excellent bath, gas, plasma nitriding and PVD-coating properties.

Good vacuum hardening properties. Through the chemical composition uniform distribution and smaller carbide size than high chromium steels.

Better toughness and electric discharge mach inability.

Application

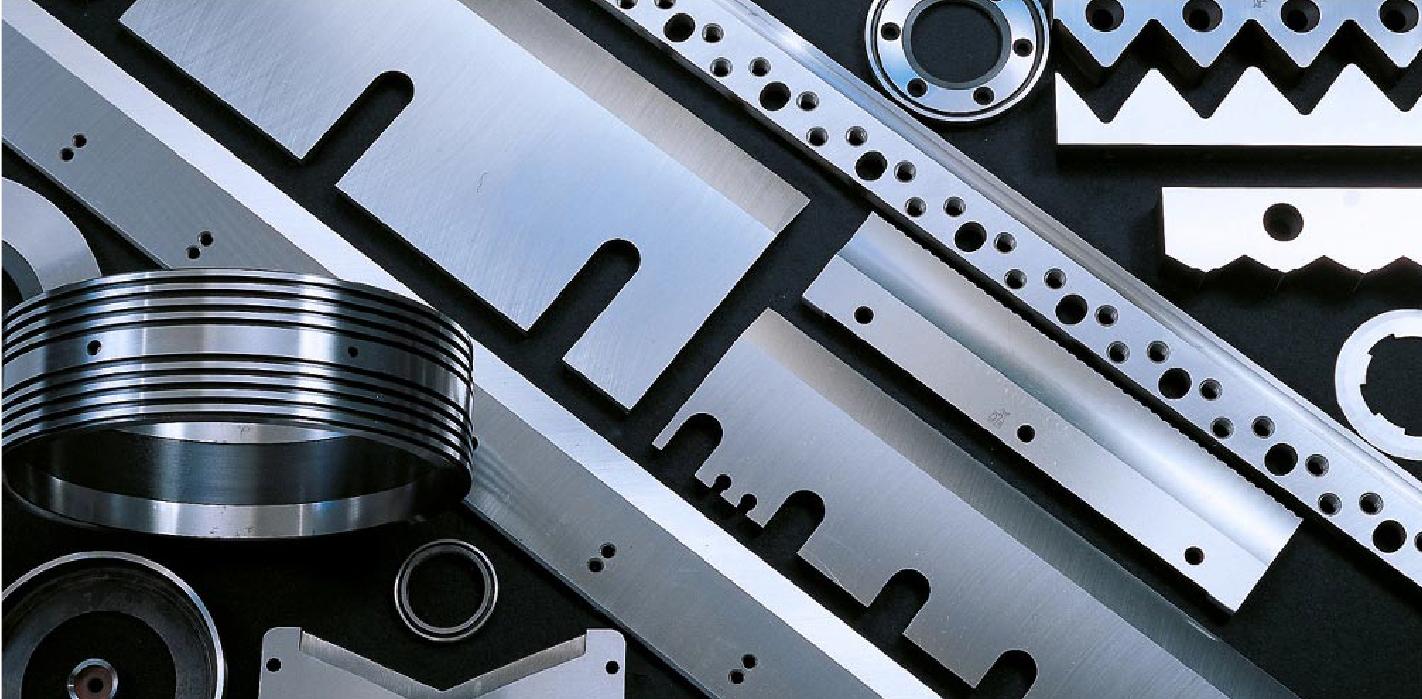

Cutting tools (dies and punches), blanking and punching tools

Cold forming tools

e.g. drawing, deep drawing and extrusion tools, coining tools, thread rolling dies

Shear blades

Measuring tools

Woodworking tools

Advantages

High retention of hardness (higher than 1.2379) also at long times, very good suitable for surface treatment, e.g. bath, gas nitriding and PVD-coating

High toughness up to 45J, approx. 3x higher than 1.2379 (dependent upop hardening and tempering temperatures)

High compression strength(0.2%-compressive strength) over up to 3000N/mm 2 (corresponding 1.2379)

High dimensional stability -0.15/+0.15%

Good wear resistance, especially when subjected to combined adhesive and abrasive friction

Very good electrical discharge machining properties

Arithmetical average roughness 20 to 30% lower than high carbon, high chromium(12%) steel.

HRC: 56-62

Heat treatment information

|

Heat treatment |

|

|

Hot forming |

1050 to 850°C |

|

Annealing |

800 to 850°C |

|

Stress relieving |

approx. 650°C |

|

Hardening |

1040 to 1080°C |

|

Tempering |

Slow heating to tempering temperature immediately after hardening/ time in furnace 1 hour for each 20mm of workpiece thickness but at least 2 hours/ cooling in air. |