Products

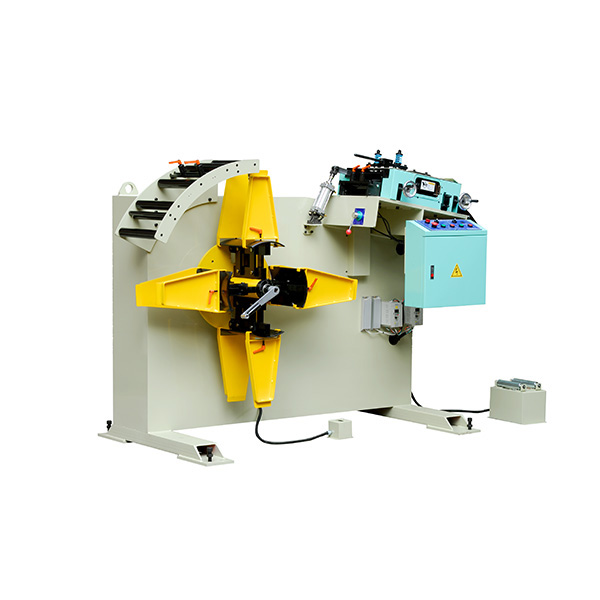

•Used to 0.2-1.2mm thick material as stainless strip, copper strip and aluminum strip which required high surface and accuracy products.

•Pedestal designed upper roller set is convenient raised to clean.

•Combined uncoiler and straightener save space and increase space using flexible.

•Upper straightener used 2 set independent adjustable device to provide individual adjustment for convenient to process high-level required products.

•Individual transmit working roller to increase surface flatness.

•Upper straightener add one auxiliary roller which could adjust material curve direction to suit customer requirement.

•Working roll use bearing steel (SUJ2) with heat treating to HRC60°, hard chromate treatment then grinding again for high hardness, high wear-resisting and long lifetime.

•Also suit long cut-to-length system.

•Suit to all kinds of feeders.

|

二合一料架整平機 (FUL型) |

|||||

|

產品型號 Model |

FUL-200 |

FUL-300 |

FUL-400 |

FUL-500 |

FUL-600 |

|

最大材料寬度 Max. material width (mm) |

200 |

300 |

400 |

500 |

600 |

|

材料厚度 Material thickness (mm) |

A:0.2~1.2 B:0.2~1.0 |

||||

|

料架荷重 Max. coiler weight (kg) |

1200 |

1500 |

|||

|

整平馬達 Straighten motor (HP) |

1 |

2 |

|||

|

捲料內徑 Coil inside diameter (mm) |

450~530 |

||||

|

最大捲料外徑 Max. coil outside diameter (mm) |

1200 |

||||

|

整平速度 Straighten speed (m/min) |

20 |

||||

|

整平滾輪直徑 Straighten roller diameter (mm) |

A:∮30*19 B:∮20*19 (Upper10/Lower11) |

||||

|

料架方式 Uncoiler method |

主動式 Master |

||||

|

擴張方式 Expansion method |

手動式 Manual |

||||

|

* 選配項目: 1.整平機出料感應為光電 2.整平馬達由變頻器驅動 3.料架馬達由變頻驅動 4.料架被動 5.傳動輪 PU 6.油壓擴張

|

|||||