Products

The series of machines is specially designed with an integrated injection circuit. The special manifold minimizes hysteresis of hydraulic response, increases injection response and is easy to maintain. With this outstanding design, you get higher qualification percentages of die casting parts and stability.

The injection circuit employs two sets of independent accumulators, providing the first and second stage injection and intensifying injection functions. With the independent intensifying accumulators, more stable intensified pressure can be achieved.

The injection unit allows for various parameter adjustments, such as pressure buildup time at the first and second stage, intensified pressure value and injection pressure value. Each part is equipped with a sensor for feeding back the injection speed and pressure to the controller. The controller will compare the difference between the actual injection value and the setting value, then the operator makes fine tuning according to the comparison result. In addition, the operator may understand the current injection condition through the displayed curve. This greatly upgrades injection accuracy.

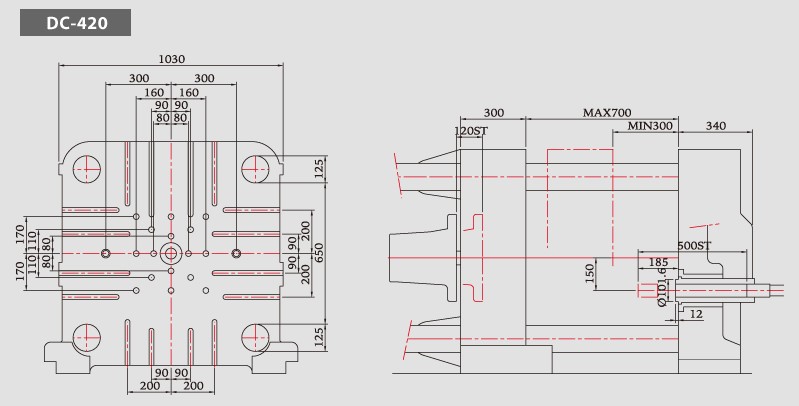

| Clamping force | 420 Ton |

| Die height | 300-700 mm |

| Tie bar distance | 650 x 650 mm |

| Max. weight of shot | 4.18 kg |

| Max. casting area | 1036 cm² |

| Electricity | 22.5 kw |