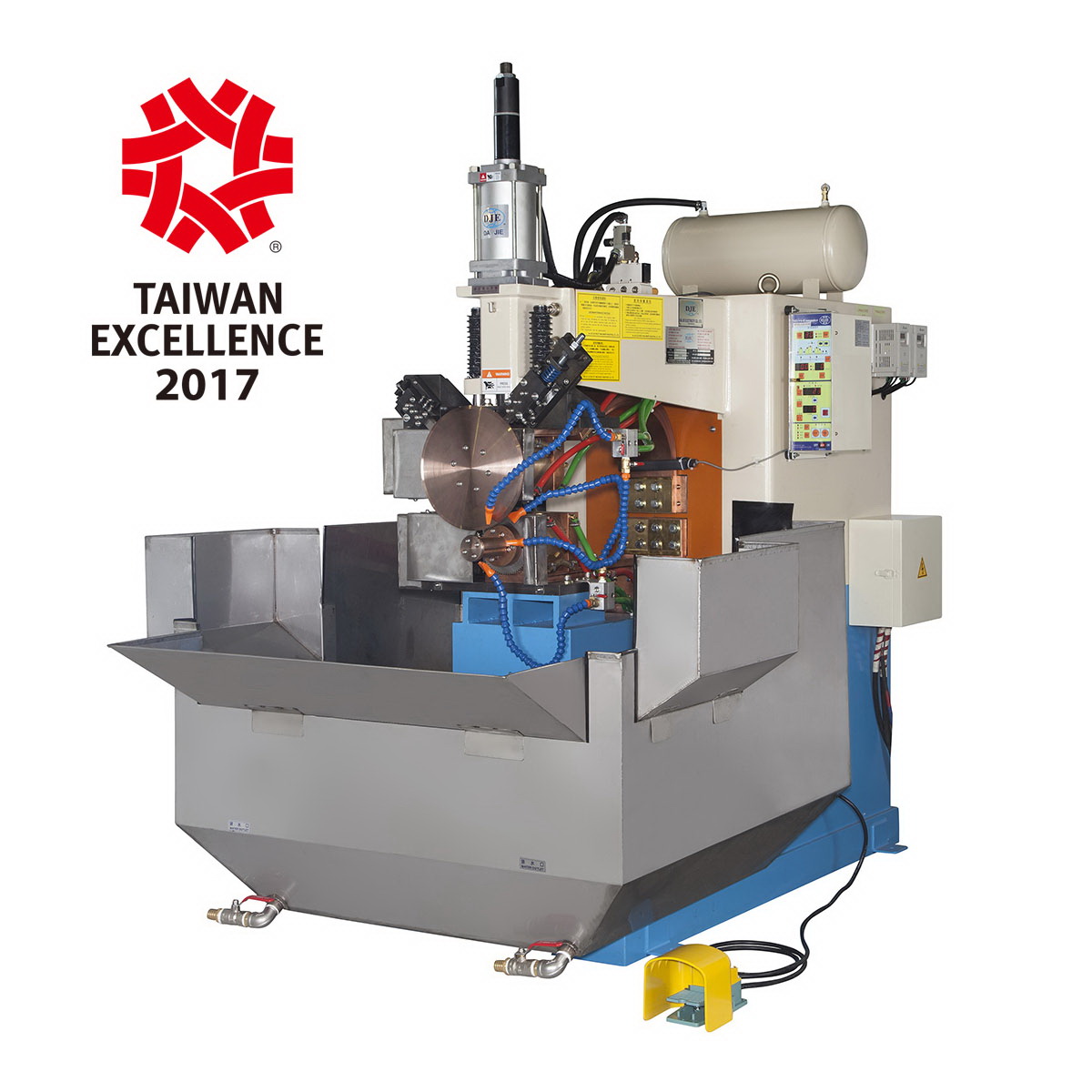

Products

1. Create Value with Innovative Technologies

The welding current meets the certification of main vehicle manufacturers and ISO standard; Enable clients to elevate the welding quality and reduce power consumption. These welding machines own highly reliable reputation by local and oversea’s customers.

2. Elevate the CP Ratio over Efficient Modularized Design and Cost Control

Apply the efficient modularized design, in the prospective of fitting the various machine models and it can fast respond client’s tailor-made and quick-repair requirements.

2.1 Modularized parts and built-in special alarm function:

30 built-in memory conditions for the varied welding currents corresponding to different products, and easy to collect data for database. Low current at current compensation, low-temperature, SCR-trigger fault or control chip error will trig the alarm system. In case the fault causes machine shutdown, client can follow the error code to replace the fault parts quickly.

2.2 Easy for repair and production; with cost-deduction favor:Reduce 20% parts amount than the former generation’s products. The intelligent control system is designed into two control module boards, which can save repair cost.

3. Humanized op. Interface

3.1 Use LED display brand and button functions are fully compatible to the machine’s operating sequence; the buttons and colors are easy to understand.

3.2 Reduce welding hazard:

The full-cover acrylic door can avoid the error-touch and sustain the reliability of op. panel.

4. Green Product’s Design

4.1 Meet CE safety standard : anti-electric-shock for entire machine.

4.2 Over 95% parts can be recycled.

4.3 Varied-frequency-control transmission system: apply the VFC transmission system to replace the traditional oil pump; no oil pollution, low noise and power-saving.

4.4 The seam welding electrode is made of Cr-Mo alloy steel, which has thermo-resisting and low-wear character, and will extend lifetime for three times.