Products

● Electro-Permanent Magnetic Chuck structure design, use the natures of different permanent magnetic materials, through electronic control system control and convert the distribution of internal magnetic circuit, magnetize the magnetic disk(i.e. in thght clamping state), and demagnetize (i.e. in loose state).

● Magnetization and demagnetization time is only 3~12 seconds. After completion, it does not need to continuously supply power to produce safe and strong magnetic force. It does not have the problem with temperature rise. It can last for a long time. The maintenance is easy. No repair is needed. It is both economic and environment friendly.

● Shorten workpiece installation time, fast mold change, save work time, increase productivity.

● Strong and stable magnetic force, assure tight fastening of workpiece, high processing precision.

Use and Applicable Areas:

● General cutting and processing for all kinds of iron parts, rapid mold change, suitable for CNC vertical computer milling machine and horizontal computer milling machine, general milling machine precision machining; the Electro-Permanent Magnetic Chuck is highly mobile, suitabke for any machine.

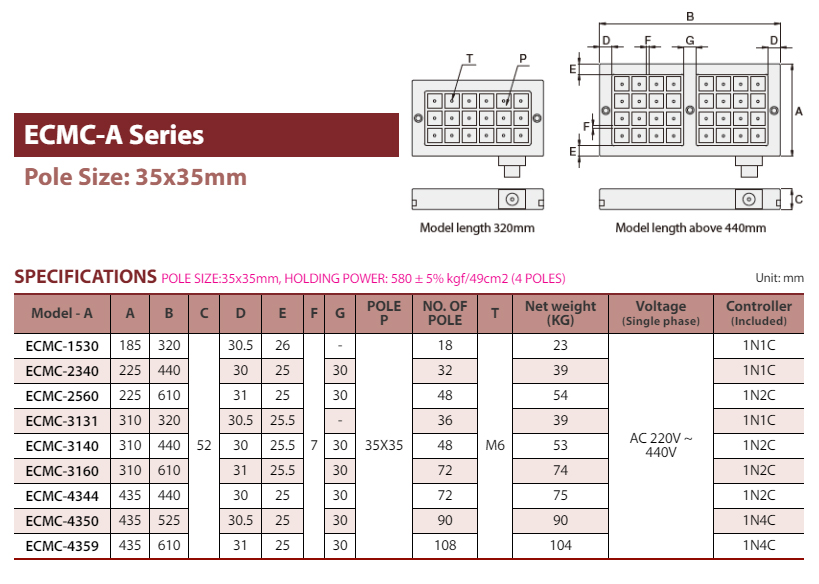

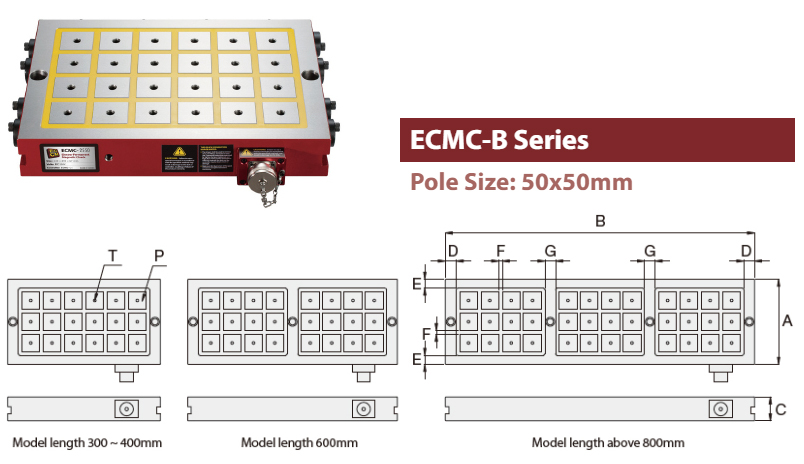

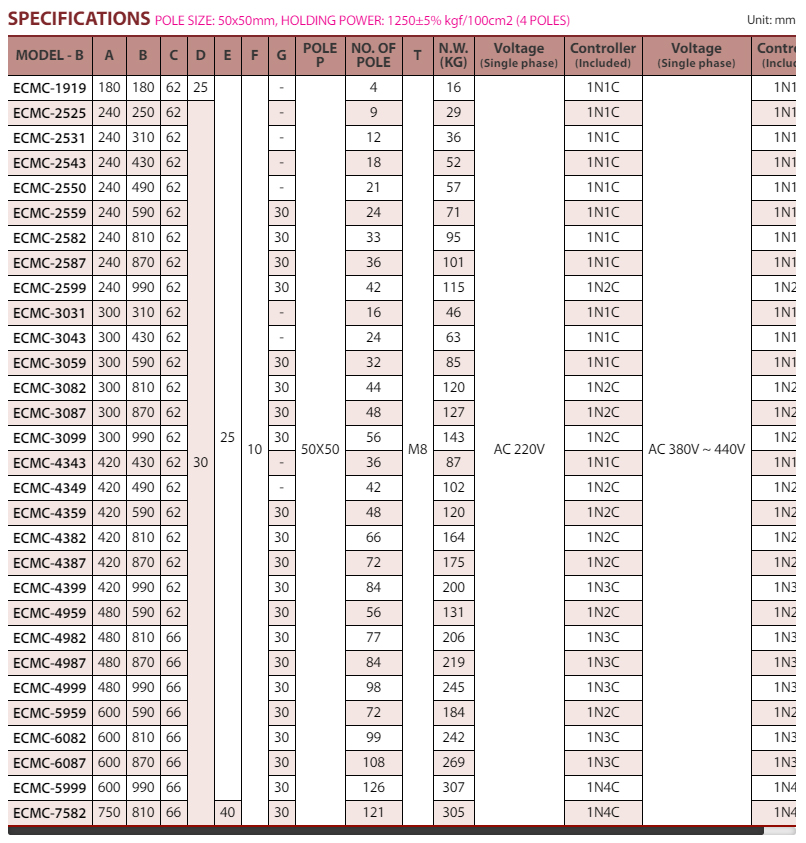

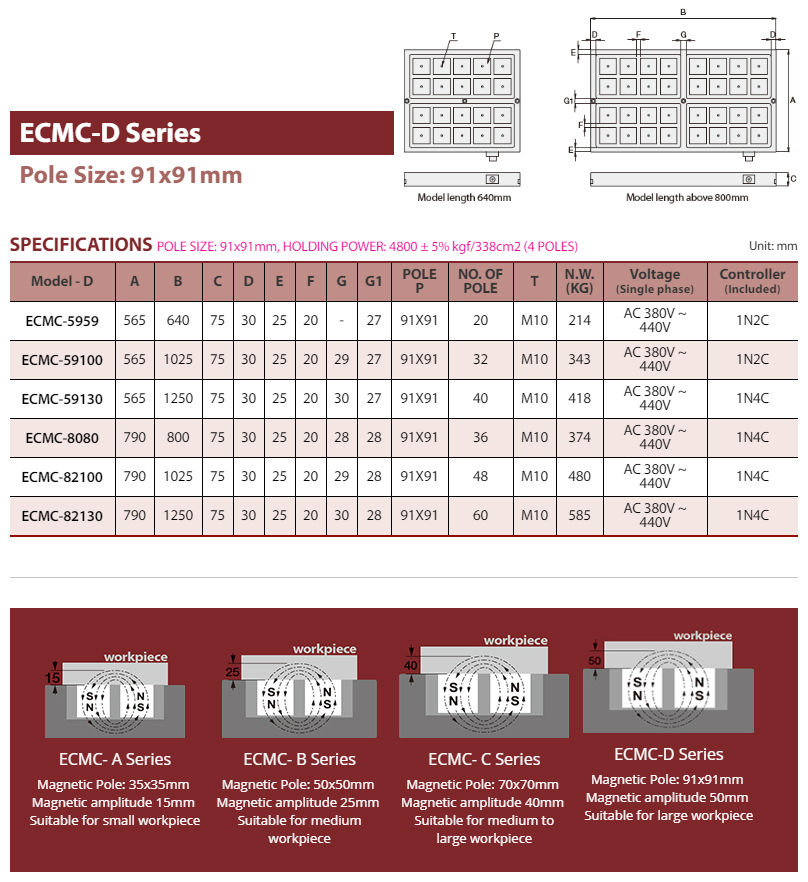

● Workpiece thickness requirement

ECMC-A Series: above 15mm

ECMC-B Series: above 25mm

ECMC-C Series: above 40mm

ECMC-D Series: above 50mm

● As workpiece is clamped, strongest magnetic force is achieved when the contact is from more than 4 magnetic poles.

● Magnetic pole dimensions 50x50mm, suitable for general cutting and processing for small and medium workpiece.

● Magnetic pole dimensions 70x70mm, suitable for general cutting and processing for medium and large workpiece.

● Work with various magnetic soft jaws and moveable spring pads, flexible adjustment and configuration accdording to pricessing needs.