Products

Features for GT-Series:

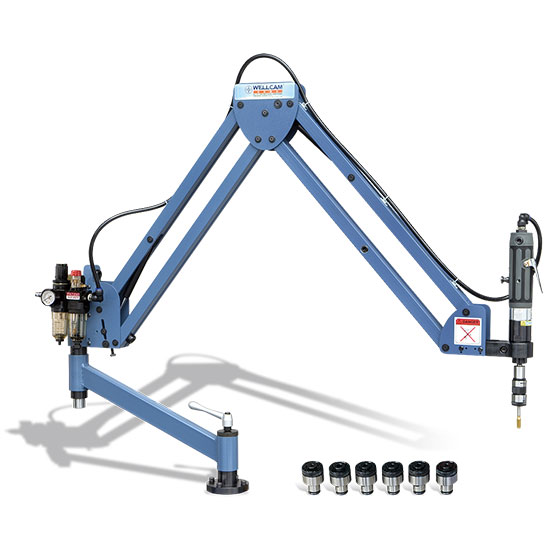

GT-Series Easier operation, quick positioning, larger working area good for both vertical and horizontal tapping

GT-10 Series Suitable for using in the industries of metal sheeting, laser cutting, stamping, aluminum casting, electrical control panel, metal parts...,etc. Increase the production efficiency and production capacity.

GT-12 Series Suitable for tapping work pieces made of FC, FCD casting, mild steel, medium-carbon steel, bigger size pieces, linear guide, this series is the most popular tapping machines used in different application.

GT-16 Series Using TC-312 #1 tap collets, the tapping machine with the largest torque in our products. It can successfully proceed M16 tapping which can be done by other machines found in the market only by changing up to TC-820 #2 TAP Collets M20.

GT-20 & GT-24 Used the tapping specification of M16, M20, M24, PT 3/8, PT 1/2 and suitable for larger work piece, smaller production lot. Good for both vertical & horizontal tapping.

| Model | GT-10VL | GT-12VL | GT-16VL |

|---|---|---|---|

| Tapping Capacity | M3 - M10 | M3 - M14 | M3 - M16 |

| Speed RPM | 700 rpm | 400 rpm | 300 rpm |

| Work Range | 300 m/m - 2000 m/m | ||

| Tapping Fixtures | TC312 - #1 | ||

| Air Pressure | 6 kg - 8 kg | ||

| Package Size | 900 m/m x 500 m/m x 200 m/m | ||

| Net Weight | 26 kg | ||

Standard Accessories

- Pneumatic Tapping spindle

- Air unit

- Parallel arm

- Choose any six safety clutch tapping adapters

- Table mounting column

- Radial jib

- Thread taps not included