Products

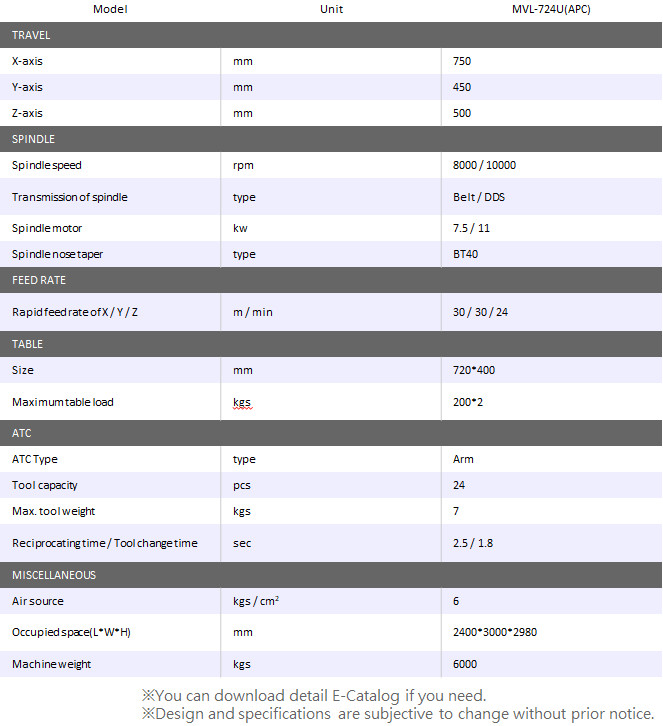

The MVL-750U from Providence is designed to meet high accuracy, high speed and high efficiency machining requirements. This machine allows the operator to set up work pieces while the machine is performing cutting, providing a reduction for non-cutting time and an increase in efficiency.

.BUILT-IN HYDRAULIC POWER UNIT AND OIL COOLER

The hydraulic power unit and oil cooler are installed in the machine to save installation space and time.

.AUTOMATIC PALLET CHANGER (APC)

Upon request, a pallet change drive by servo motor is available.

A air blast device is applied for cleaning the positioning cones before pallet positioning; hence hih positioning accuracy is ensured.

.COUNTER BALANCE WEIGHT PROPERLY GUIDED FOR INCREASED STABILITY

The counter balance system on the Z-axis has a guide that allows the spindle head to move stably, resulting in higher machining accuracy.

.UNIFORM LUBRICATION ASSURED

A volumetric oil distributer is equipped in the lubrication system to ensure uniform oil supply to each lubrication point.

The use of the oil distributer also helps improve motion smoothness of all axes.

.RUGGEDLY CONSTRUCTED SADDLE AND TABLE

The box shaped saddle and table are specially designed to provide heavy load resistance capability, resulting in better machining accuracy.