1YRS

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Products

Specification

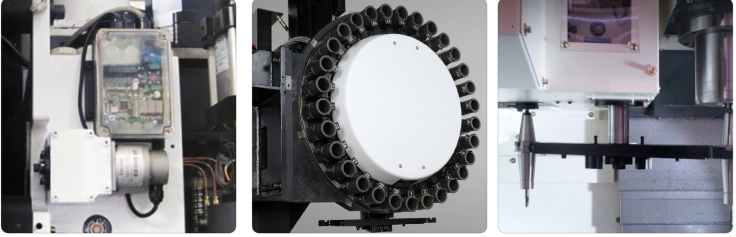

YCM In-house IDD Spindle

- Tool unclamping cushion extends spindle bearing life by protecting spindle bearing from tool unclamping force.

- Spindle cooling system (opt.) removes heat efficiently and minimizes thermal deformation.

- Ceramic bearings features low inertia mass, low centrifugal force, high rigidity and low coefficient of thermal deformation.

- High precision helical springs features high dynamic balance and low vibration.

- Grease lubrication for 12,000 rpm spindle ; Oil-air lubrication for 15,000 rpm spindle (opt.) .

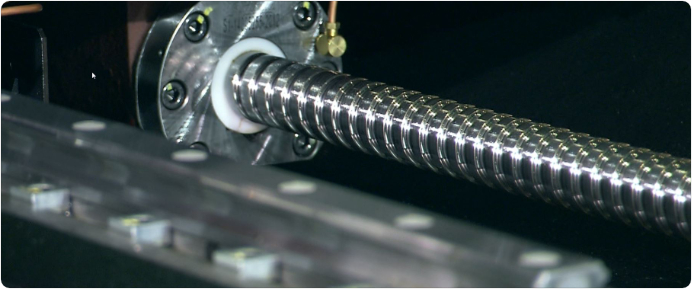

High Rigidity Design

- FEM analysis is adopted to ensure the best mass arrangement and rib construction of the machine for constant stability under the intensive load of heavy-duty cutting.

- Direct drive provides backlash free, best accuracy, reliability and stability.

- All axial AC servo motors equipped with Absolute Positioning Encoders, no zero return needed

- The rigid body construction makes for uncompromising precision and rigidity.

High Stability Tool Magazine

- Absolute encoder ATC system provides high stability and speed.

- Inverter controlled, prevents tool change speed from changing under different power supply frequency.

- Tool change speed can be adjustable for heavy tools.

- Auto Tool Change (T-T) 1.8 sec.

- Tool Magazine Capacity: 24T

Automatic Tool Magazine Door Design

- Driven by pneumatic cylinder.

- Prevent coolant and chips from entering tool magazine.

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Coolant shower for efficient chip removal

Automatic Pallet Change

- Pallet Size: 560 x 410 mm 22.04" x 16.14"

- Table Load Capacity: 120 kg 265 lb

- Distance Between Spindle Nose and Table Top: 25 ~ 475 mm 0.98"~18.7"

- Hole Pattern: M12 x 80 mm x 80 mm M12 x 3.15" x 3.15"