1YRS

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Products

Horizontal Machining Center

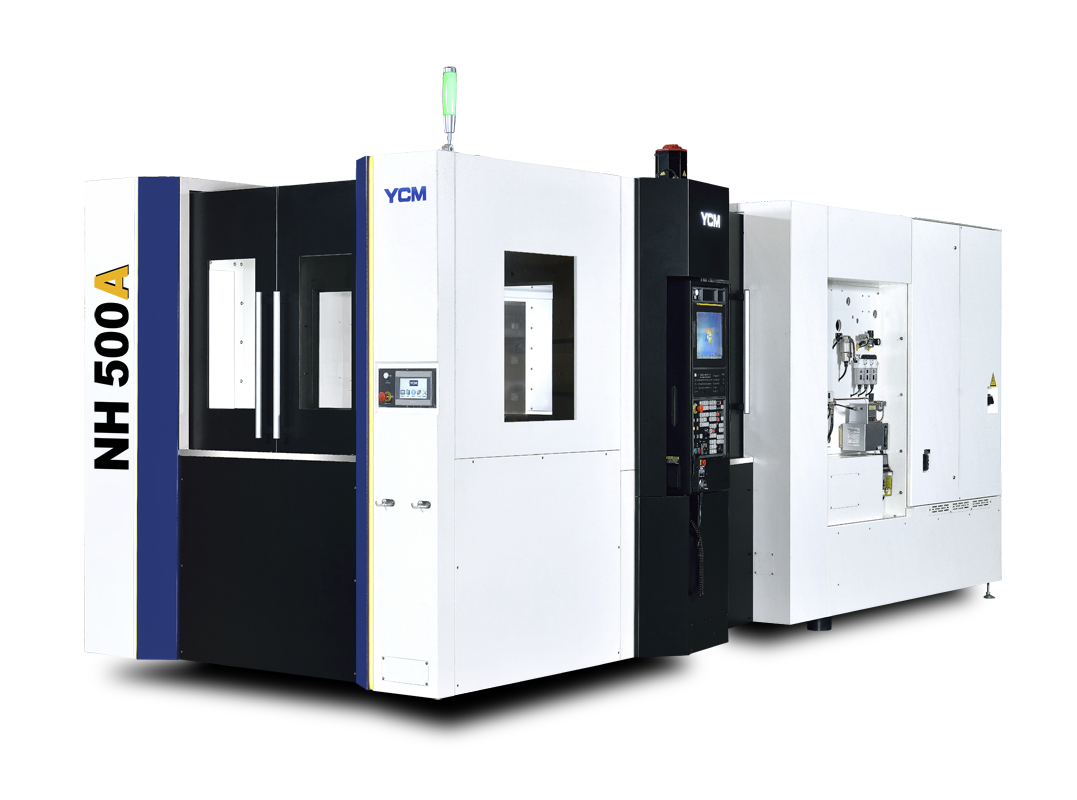

NH500A Horizontal Machining Center

NH系列

NH series - High Production 2-Pallet HMC's with Fast Spindle and Rapid Speeds for Increased Productivity.

Specification

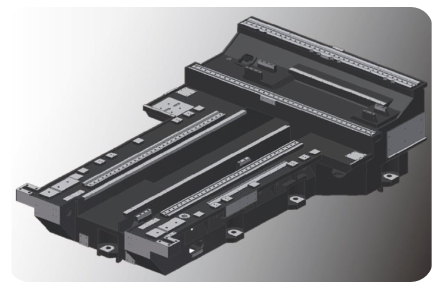

High Rigidity Structural Design

- One piece T-type base structure with rib construction for unprecedented rigidity.

- Dual-wall column design for enhancing rigidity and durability.

- Adopted FEM analysis for lightweight design to improve G value that can prolong ballscrew life and reduce energy consumption.

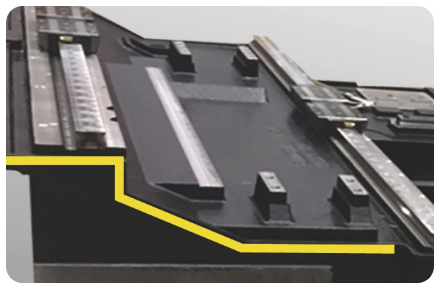

Stepped Design on X-axis

- Two X-axis guideways are positioned at different height to increase stable and reliable rapid axial movement.

- Compact column design is able to achieve higher acceleration and performance.

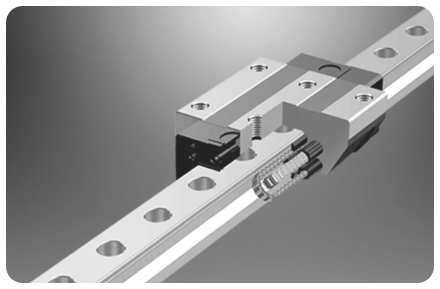

All Roller Type Guideways

- XYZ axes are equipped with roller guideways to increase rigidity and accuracy.

- High dynamic AC servo driven pre-tensioned ball screws, delivering high control qualities.

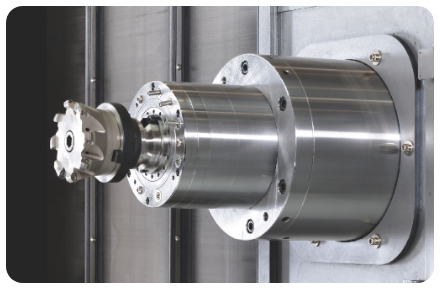

Powerful IDD Spindle

- The standard IDD spindle design, easy for maintenance 15,000 rpm max. spindle speed with 37 kW output delivers 244 Nm torque.

- The powerful spindle utilizes high precision ceramic ball bearings.

- The spindle oil cooling system effectively minimizes thermal deformation.

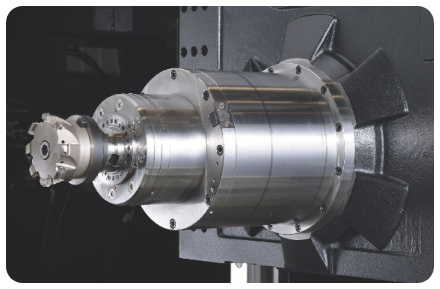

High Performance Built-in Motorized Spindle (opt.)

- The max. spindle speed reaches up to 20,000 rpm with 22.5 kW output delivers 61 Nm torque.

- Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life.

- Circulated oil jacket cooling system minimize thermal deformation, ensuring high accuracy.

- Easy spindle unit replacement reduces maintenance time.

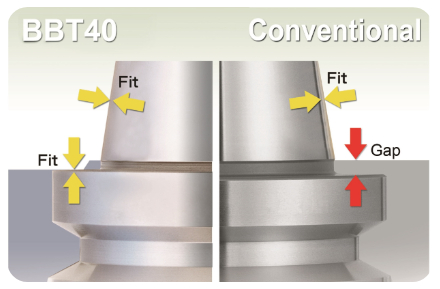

BBT40 Dual-Contact Spindle Taper

- Equipped with BBT dual-contact to improve cutting capacity and accuracy, also enhance spindle and tool life.

Optimized Spindle Design

- Coolant through spindle system: 20 bar (std.) / 70 bar (opt.).

- Spindle air seal protected.

- Labyrinth protection design.

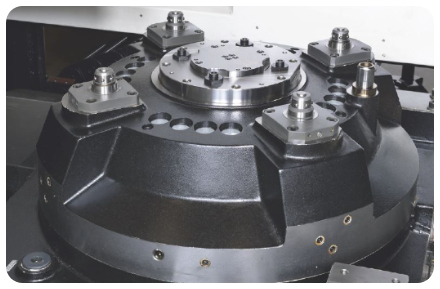

Reliable Automatic Tool Change

- It takes 2 seconds to complete one cycle of tool to tool change.

- ATC speed is programmable in high & low speed.

- Servo motor driven tool magazine.

- 60T for disc type tool magazine (std.).

- 120T for chain type (opt.).

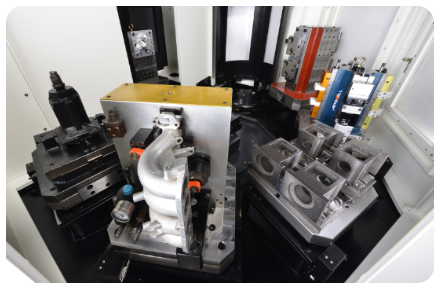

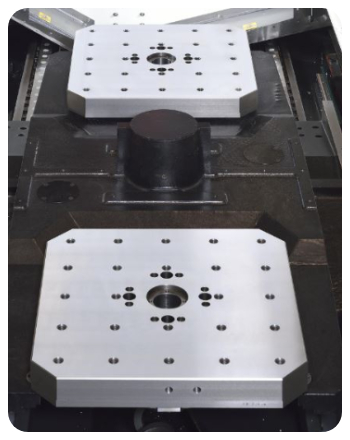

Automatic Pallet Change

- 11-second pallet change servo motor driven.

- Maximum table rotation speed: 22.2 rpm/min

Dependable Pallet Indexing System

- Flange contact taper cone with excellent clamping power and high pallet-positioning precision.

High Efficiency Six Pallets System for Flexible Production Needs (opt.)