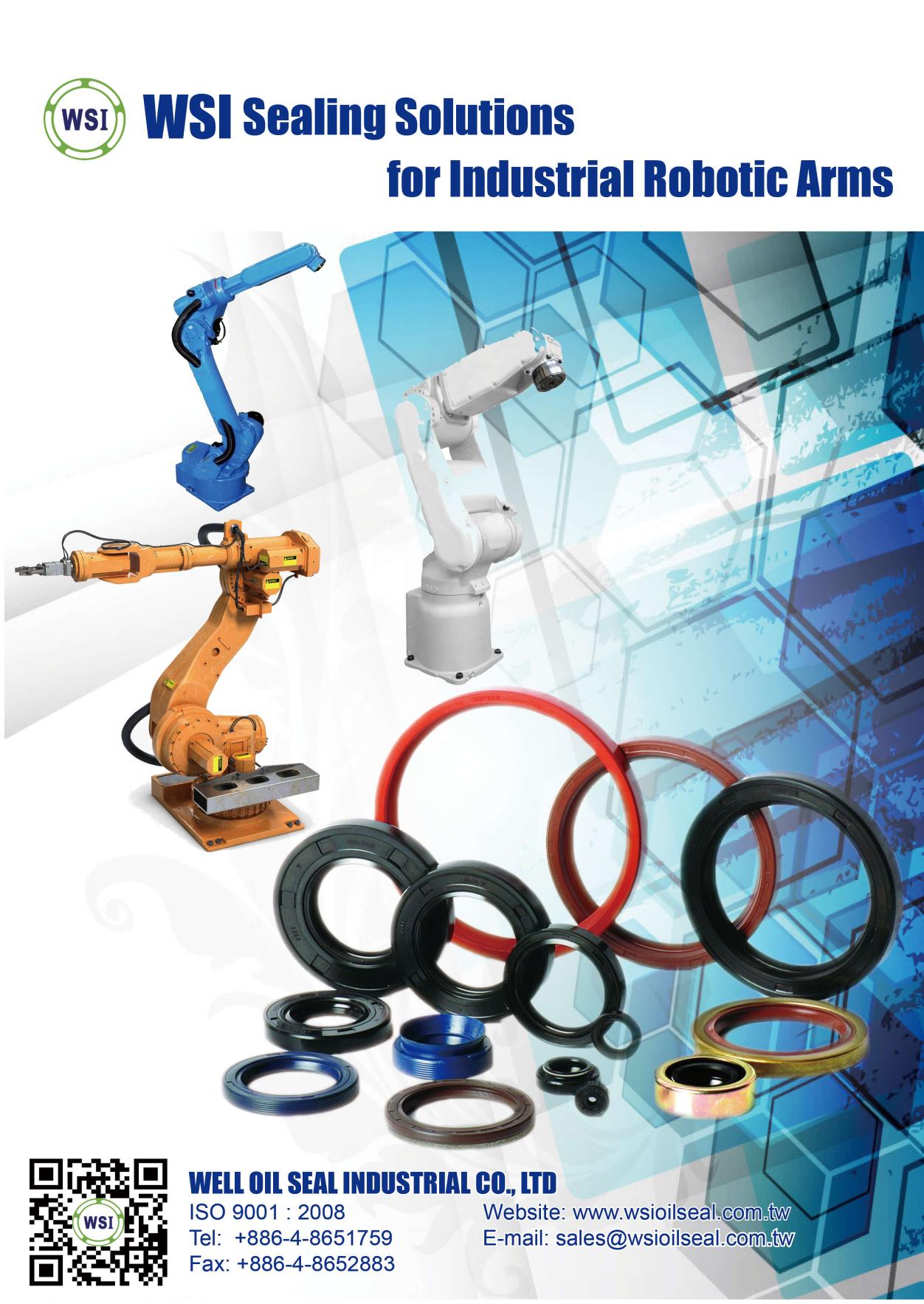

Products

Under rapid technological development, human operation has gradually been

replaced by the robotic arm, and become indispensable in modern industrial

machines. The robot arms can be autonomous or controlled manually and can be

used to perform a variety of tasks with great accuracy, due to it is programmable to

perform as a human arm.

The robotic arm in the industrial automation applications has been quite extensive.

The robotic arms are being widely applied in automation industrial however the

demand is varied in each region due to various industry distributions. It is mainly

applied in activities that human are unable to accomplish or time costing tasks. The

robotic arm can reduce unpredictable artificial problems of accuracy and durability.

WSI sealing solutions for industrial Robotic Arms include rotary seals, V-seals,

O-rings, and end caps.

Rotary seals are used for lubricant retention and contaminant exclusion while V-seal

is generally for dust exclusion. The chosen seals lip materials are determined by

the operating environment such as temperature, sealing media, pressure and rotary

speed. The most common materials used for rotary seal application include NBR,

HNBR and FKM.

O-ring is used primarily for sealing. It is a circular cross-section ring molded from

rubber.

O-ring is fit into the groove and sealing surface have been applied significant

pressure that have compressed and deformed the O-ring for sealing function.

End cap is designed for static sealing as a plug or barrier which is compatible with

both grease and oil lubricants.

Additional elastomeric compounds to fit different applications are available upon

request. Please contact us for more information.

Overview

DescriptionAdvantages of rotary seals for industrial robotic arms I

• Good O.D. static sealing

• Excellent lubricant resistance

• Low friction

• Capable of sealing larger surface roughness

• Customized sealing solutions

Advantages