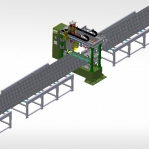

Products

1. This machine adopts Three Phase Inverter DC (MFDC) welding system that is drawings very minimal primary current and requires Dynamic Electricity of only 100kVa total.

2. German imported Bosch Rexroth Inverter DC Power Supply ensures constant welding current, hence constant current output

3. The machine uses pneumatic system. No hydraulic unit, less hassle in service in the future.

4. The machine is water cooled to the electrode which ensures longer electrode life and weld quality

5. The machine is controlled by PLC for accurate welding distance and movement

6. Dahching’s experience in Electrode-Forged Grating Welding machine applied here. Grating quality produced by this machine is ensured.

7. Machine equipped with user-friendly interface, easy to troubleshoot and stable machine quality.

Thickness of Bearing Bar (A)3mm ~ 6mmHeight of Bearing Bar (B)30mm ~ 50mmCross Bar (C)5.0 ~ 6.0 mm (Square Rod) Ø6.0 ~ Ø8.0mm after TwistingPitch between Bearing Bars (D)30mm ~ 50mmPitch of Cross Bars (C)50mm or 100mmPanel Length6000mm max.Panel Width1000mm max.Cycle Time45Min / Grating

- Excluding Loading and Unloading by Operator

- Panel Size 1000mm*6000mm

- Cross bar pitch 100mm

WeldabilityWeld electrode: 90~120mm max

- Cross Bar: 6mm Square Bar (Dia. 8mm after Twisting)

- Max 6 Points (3 bearing bars) for 3mm Bearing Bar

- Max 4 Points (2 bearing bars) for 5mm Bearing Bar

- Cross Bar: 5mm Square Bar (Dia. 6mm after Twisting)

- Max 10 Points (5 bearing bars) for 3mm Bearing Bars

- Max 8 points (4 bearing bars) for 5mm bearing bars

No. of Cross Bar WeldingWelding 2 in 1 stroke