● drylin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides.

Technical data

| Gliding elements: | Maintenance-free |

| Material: | iglidur® J* |

| Max. surface speed: | 15 m/s |

| Operating temperature: | -40°C to +90°C |

| *Other materials on request |

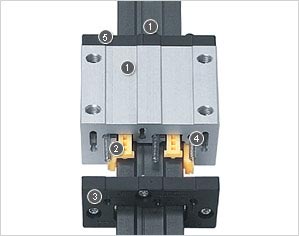

- Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized.

- Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings.

- Alternatively, bearing clearance is continuously adjustable

- All steel parts are stainless steel

- The lid is made of solid plastic or stainless steel

Advantages:

● 100 % lubricant-free

● Adjustable bearing clearance

● Automatic clearance adjustment

● High static load capacity

● Service life up to 50,000 km without lubrication

● High dirt resistance

● Low vibration and low noise

When not to use ?

● When you want to save installation space

drylin® N

drylin® W

● When you need a pure stainless steel solution

drylin® W

drylin® R

● When you want to construct as economical as possible

drylin® N

drylin® W