Products

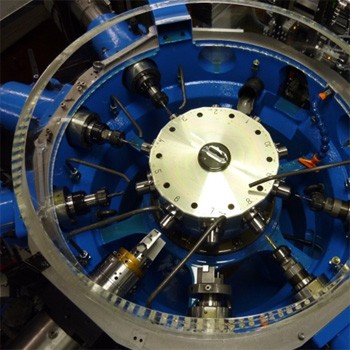

Rotary Transfer Machine has been recognized as the most powerful machining equipment for small components in huge quantity. 2 to 6 seconds cycle time has given mass production a cutting edge in making complicated machining process. Following special features you may find from rotary transfer machine.

- Material can be fed into the machine from bar or from coil.

- Index time is in fractious second.

- Inverting unit will bring and rotate the part 180˚, so both sides can be machined in the machine.

- 12 stations can divide all machining works into multi stations. And they work simultaneously, so cycle time has been divided into 12 stations, and production gets very high.

- Swiss craft makes machine durable and precision.

- Various machining can be done on Rotary Transfer Machine such as:

a. drilling

b. turning

c. tapping

d. milling

e. thread rolling

f. recess

g. cross drilling

h. polygon turning

Example

Part: fitting

Machine specification and layout:

|

Station |

Operation |

Unit |

Tool Head |

|

1 |

Cut off |

A.E. |

Guide Bush |

|

2 |

Form drilling Ø4.5 mm |

VE 20/80 |

Drilling head |

|

3 |

Turning, chamfer, facing |

VE 30/60 |

Turning head |

|

4 |

Threading NPT 1/8-27 |

GWE 30/60 |

Threading head |

|

5 |

Drilling Ø3.8 mm |

VE 20/80 |

Drilling head. |

|

6 |

Inverting |

WDE 20/50 |

Inverting bush |

|

7 |

Form drilling Ø4.8/5.9 mm |

VE 20/80 |

Drilling head |

|

8 |

Turning Ø9.0, chamfer, facing |

VE 30/60 |

Turning head |

|

9 |

Turning threading |

VE 30/60 |

Turning head |

|

10 |

Threading 7/16-20 UNF 2A |

GWE 30/60 |

Threading head |

|

11 |

Tapping 5V1 |

GWE 30/60 |

Drilling head |

|

12 |

Drilling cone 17˚ |

VE 20/80 |

Drilling head |

Table index time:0.5 second

Longest machining time:2.5 second

Total cycle time:3.0 second

Production:1200 pcs/hour

Refurbished Machine

Since the brand new machine is quite expensive, there are hundreds of used machines in the market. So we take used machines to rework these machines to customer requirement.

▲ Before Refurbished ▲ After Refurbished

Every application is different. We change spindle units, rework spindle unit by changing all bearings, seals, o-rings, cable, tube. We make all new electrical control system….etc. After rework, the machine is like new. We have put down photos showing the machine before refurbished and after refurbished. If you have inquiry or requirement, let our engineer do an analysis.