Products

Design

High speed ball bearings, with smaller rolling elements, HS bearings are able to withstand higher rotating speed than the standard design.

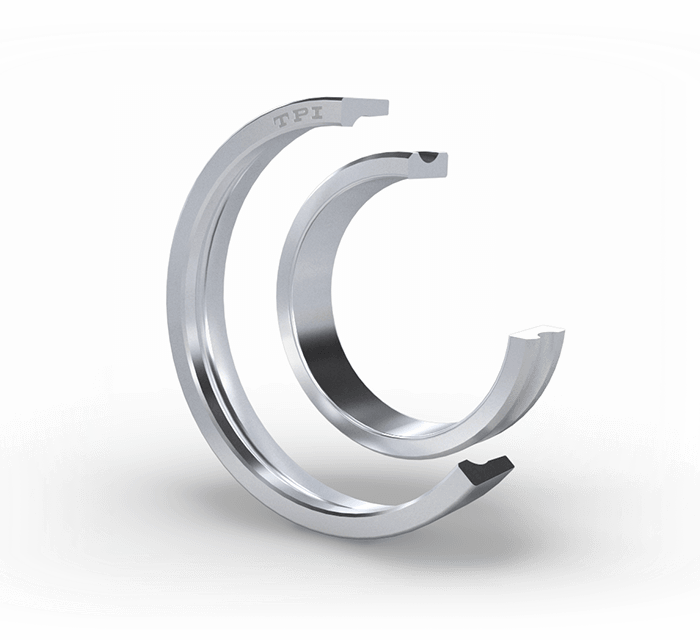

Inner and outer rings

Standard bearing steel with a content of carbon and chromium was selected and hardened to withstand the intense pressure between the rolling elements and bearing rings.

Carbonitriding on both inner and outer rings is a basic hardening process for TPI high speed ball bearings. Through this special heat treatment, hardness on the raceway surface is increased; which reduces wear accordingly.

Ultra-clean steel is available in some of TPI ball bearings manufacturers' product series now, higher wear-resistance is obtained accordingly. Since contact fatigue is often caused by hard non-metallic inclusions, high speed ball bearings nowadays require exceptional levels of cleanliness.

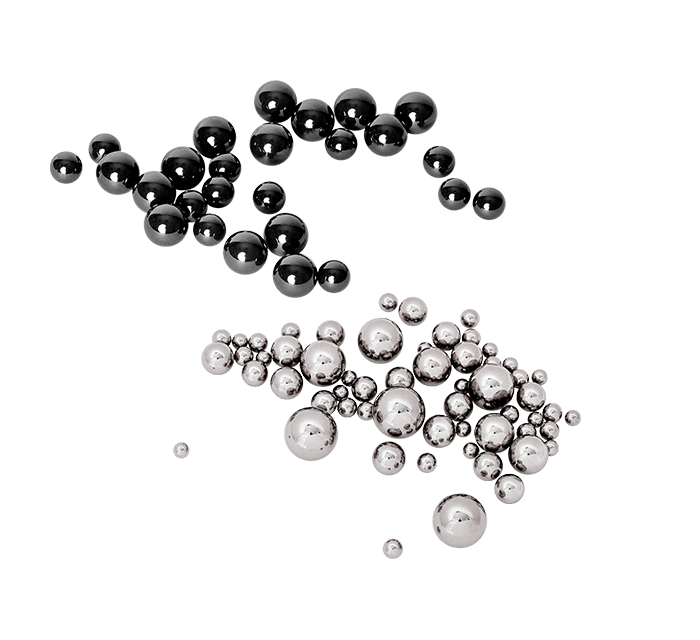

Rolling element

High precision steel balls ensure TPI's high speed ball bearings have the best precision and stability. This also reflects in bearing performance under high speed rotation.

A ceramic ball is an additional option when it comes to severe operating conditions. Extreme high speed rotation, heavy-duty applications, and high heat generation while operating are some situations that ceramic balls that can definitely help.

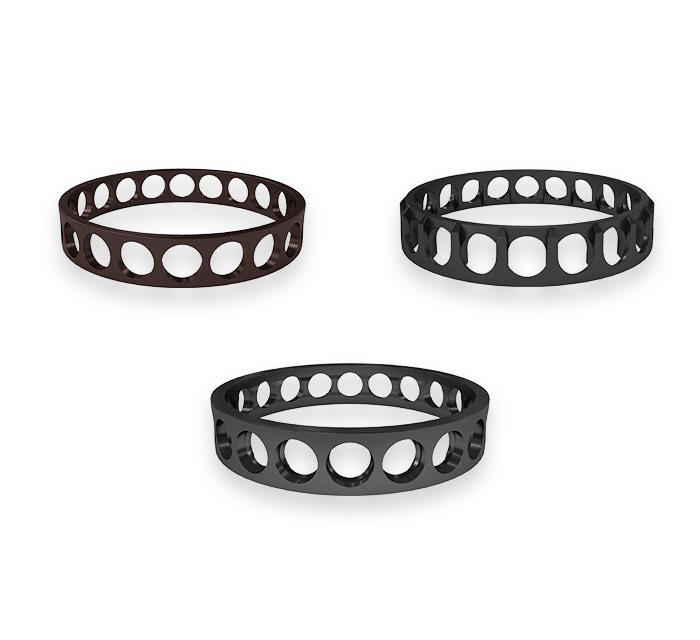

Cage

With the highly engineered arrangement of cages, remarkable characteristics were achieved.

T1 cage, desinged for the requirement of high RPM and stable temperature rise.

T2 cage, desinged for low noise level, however, the temperature rise in high RPM is relatively high.

T3 cage, improvement of T2 cage, it's not only applicable to high RPM operation but also remain low noise level under low RPM.

Seal

The non-contact seal provides general protection for high speed ball bearings. It cannot prevent liquid contamination from getting into the high speed ball bearings. Torque and limiting speeds are the same as the open type.

Grease

For HS series bearings, grease selection must focus on the grease viscosity and penetration. Since the rotating speed of HS series bearing application is normally higher than standard series, bearing lubrication and heat generation shall be carefully considered during grease selection.

Life

Bearing life is usually expressed as the number of hours an individual bearing will operate before material fatigue develops on either the raceways or the rolling element. The usual life rating for industrial applications is called “L10” life. The L10 life is the number of hours which that 90% of bearings will survive; or, conversely, 10% of bearings will have failed in the L10 number of service hours.

Preload / Rigidity

System rigidity, one of the main factors of productivity and accuracy when it comes to machine tools and other precision applications. By preloading the bearings, it becomes extremely rigid and the magnitude of elastic deformation becomes neglectable.

Arrangement

High speed ball bearings in duplex arrangements vary in combinations of two, three, or four, in accordance with the user's required specifications.

Back-to-back duplex (DB) arrangement and face-to-face duplex (DF) arrangement can both sustain radial and axial loads in both directions. The wider distance between the effective load centers of the DB arrangement allows larger moment loads to be handled.

Designation

The designation indicates the form, size, precision, internal structure, etc. of the bearing, and it's shown as below:

| Ball material | 5S1- | Si3N4 (Ceramic ball) |

| Blank | SUJ2 (Steel ball) | |

| Bearing type | 7 | Single-row angular contact ball bearing |

| HS | High speed angular contact ball bearing | |

| BT | High speed angular contact thrust ball bearing | |

| Diameter symbol | 9 | |

| 0 | ||

| 2 | ||

| 3 | ||

| Bore number | 6 - 26 | below number 03 00: 10mm 01: 12mm 02: 15mm 03: 17mm above number 04 bore number x5 mm |

| Contact angle | C | 15° |

| CE1 | 18° | |

| AD | 25° | |

| A | 30° | |

| B | 40° | |

| Blank | 60° | |

| Cage symbol | T1 | Phenolic machined cage |

| T2 | Engineering plastic molded cage | |

| T3 | Engineering plastic molded cage | |

| Bearing arrangement | DB | Back to back arrangement |

| DF | Face to face arrangement | |

| DT | Tandem arrangement | |

| DBT | Tandem and back to back (triple-row) | |

| DTBT | Tandem and back to back (quad-row) | |

| Flush grinding | G | Flush ground type |

| Blank | Without flush ground | |

| Preload | GL | Light preload |

| GN | Normal preload | |

| GM | Medium preload | |

| GH | Heavy preload | |

| GXX | Special preload | |

| Accuracy | P5 | JIS standard class 5 |

| P4 | JIS standard class 4 | |

| P4X | JIS standard class 4, Special bore and outside diameter tolerance | |

| P42 | JIS standard class 4 (dimensional)、 JIS standard class 2 (running accuracy) | |

| P2 | JIS standard class 2 |