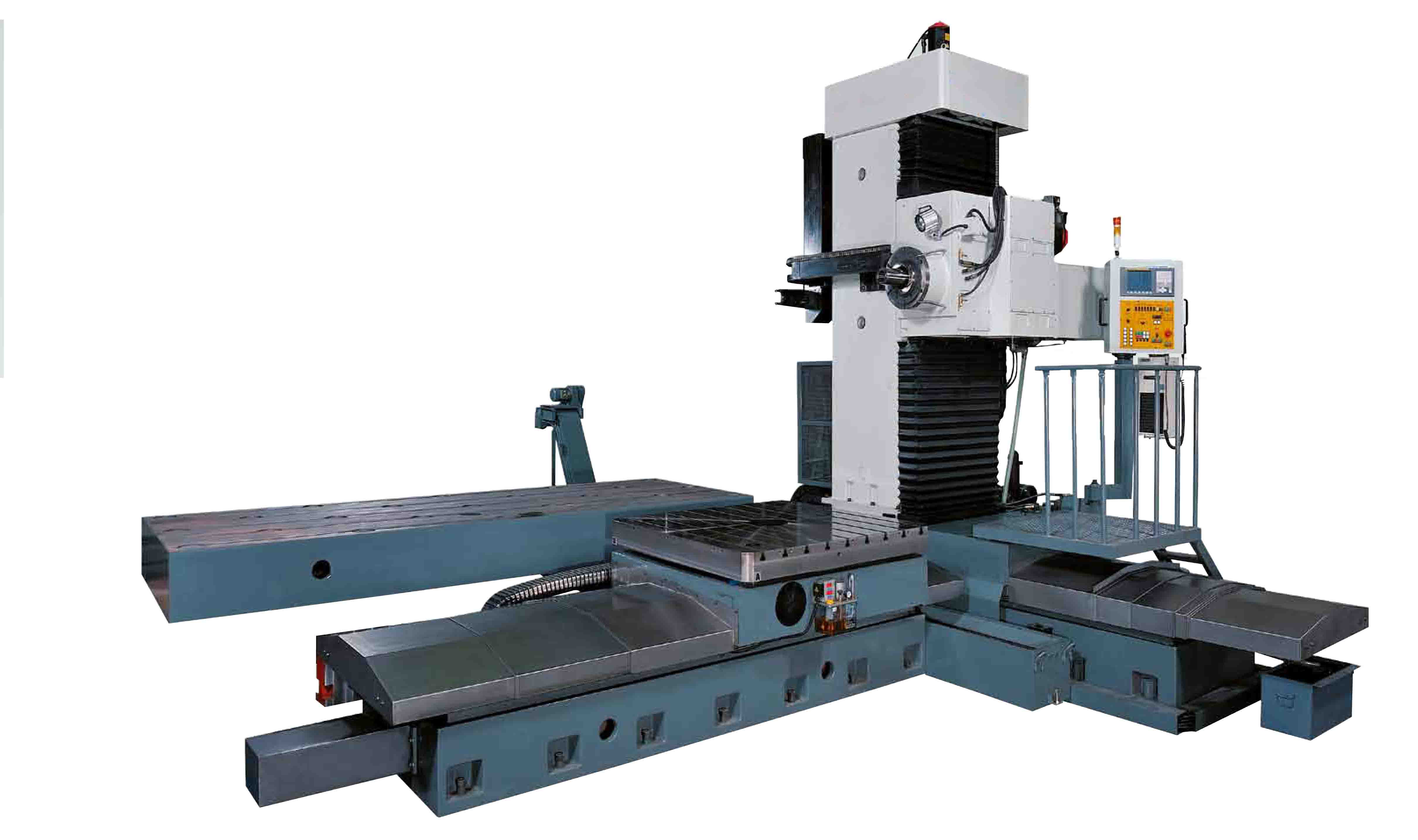

Products

Features

● High Power Spindle

- Variable speed and high torque are a function of the 22kw AC motor (30 min. rating).

- For the spindle bearings, super precision, highly rigid tapered roller bearings are employed. These bearings ensure high precision and high rigidity of the spindle with minimal heat generation. The machine is equipped with a cooling device for the lubricant inside the headstock.

- The spindle nose is a 7/24 taper No. 50.

● High Positioning Accuracy through CAD designed rib casting.

- For the vertical travel of headstock, the spindle travel and the quill feed, high quality ball screws are used. All sliding surfaces are automatically lubricated at key points.

-The clamps for headstock vertical travel, column cross traverse, and quill travel are heavy-duty hydraulic type.

-The major structural members are box-shaped with best possible arrangements of ribs with a large cross-sectional area, providing highest rigidity long-term accuracy and precision.

● High Precision Slideways

- The mating surfaces of the moving units are coated with a special fluorine resin, and forced-lubricated so that the system for slide ways offers minimum friction resulting in high precision which will be maintained over a long period of time, this ensures a very smooth feed stroke even at low speeds without stick/slip.

● Rotary Table -CRT Series

- The bed slide way is hardened and ground, and equipped with an automatic lubricating system.

- NC-controlled, the saddle feed (V-axis) is driven by high-precision ball screw.

- With the rotation of the rotary-table indexed to every 90 degrees controlled by the M-command.The digital read-out counter is standard equipment calibrated to 1 minute.

Specifications

| Description | BRM-110F | ||

| Spindle | Main Motor (30min/cont.) | kw (HP) | AC 18/22 (24/29) |

| Spindle Speed | rpm / min | 5-2500 | |

| Spindle Tapper | ISO 50/BT-50 | ||

| Spindle Diameter | mm(in) | 110(4.33) | |

| Max. Spindle Torque | Nm(kgm) (ft, lbs) | 1245(127) | |

| Max. Spindle Thrust | N(kgf), (ft,lbf) | 19600(2000) | |

| Travel | Column Travel X axis (Horizontal) | mm(in) | 2000-6000: Ball Screw |

| Above 6000: Rack | |||

| Spindle Vertical Travel Y axis | mm(in) | 2000(79) | |

| 2500(98) | |||

| 3000(118) | |||

| Spindle Travel W axis | mm(in) | 600(23.62) | |

| Feed Rate | X / Y axis | mm/min(in/min) | 6000(236) |

| V / W axis | mm/min(in/min) | 4000(157) | |

Rotary Table (CRT-Series)

| Description | CRT-18/20B | CRT-20/25B | |

| Table Size | mm(in) | 1,800×2,000 (70×78) | 2,000×2,500 (78×98) |

| Table Rotating Maximum Dia | ψ mm(in) | 2,565 (101) | 2,970 (117) |

| Saddle Traverse (V Axis) | mm(in) | 1,000 (39) | 1,500 (59) |

| Work Table Max. Loading Weight | Kg (lb) | 12,000 (26,400) | 20,000 (44,000) |

| Work Table Rotation Speed | min-1(rpm) | 0.8 | 0.8 |

| Saddle Cutting Feed | mm/min (in/min) | 1~3,000 (0.04~118) | 1~3,000 (0.04~118) |

| Saddle Rapid Traverse | mm/min (in/min) | 6,000 (236) | 6,000 (236) |

| Max. Thrust | N (kgf/lbf) | 19,600 (2,000/4,410) | 29,400 (3,000/6,615) |

| Electric Power Source Capacity | KVA | 14 | 14 |

| Machine Size | mm(in) | 3,650×2,560×750(143×101×30) | 4,920×3,110×925(194×122×36) |

| Work Table Weight (est.) | kg (lb) | 8,500 (18,700) | 15,000 (33,000) |

| T-slot | Pitch × number | 185×9 | 200×9 |

ATC

| Automatic Tool Changer (Optional Accessory) | |

| ATC Capacity | 40/60/90 |

| Tool Shank | MAS 403 BT-50 |

| Pull Stud | MAS 403 P50T-1 |

| Tool Weight | 25kg |

| Max. Tool Length | 300mm |

| Max. Tool Diameter | Ф125mm(Ф250mm) |