Products

structure

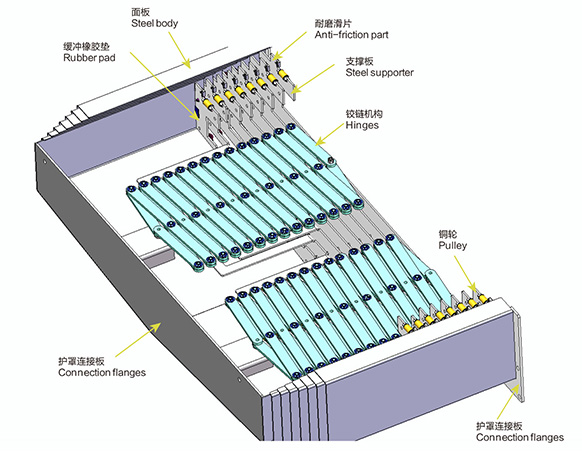

The steel plate protective cover is mainly assembled by the basic structure of the main panel, the supporting plate, the sliding plate or the pulley, the hinge mechanism, the scraping strip, the buffer rubber pad, the protective cover connecting plate, etc.

Material

All use high-quality materials at home and abroad, commonly used are SUS304, 1Cr13, cold-rolled plate, etc., and use high precision laser cutting machine and precision CNC bending machine for processing

Technical Parameters

According to the actual operating range and operating speed of the machine tool, it is possible to calculate a more accurate number of steel shield sections and to choose reasonable accessories (such as: operating speed ≤10m / min, wear-resistant slide or roller can be used; Hinge mechanism, copper wheels and other accessories are required);

generally, the number of sections of the steel plate shield should be as few as possible, so that it can reduce the weight of the shield, reduce costs, and improve its operating characteristics;

design expansion The ratio is generally between 3: 1 ~ 5: 1

Features

The fitting degree of each section of the steel plate protective cover is relatively tight, and does not affect the running speed, it can effectively prevent foreign objects such as dust, iron dust, and coolant; its excellent quality and long life, Beautiful appearance, can be stamped on the machine without deformation

application

The steel plate protective cover is widely used in the mechanical equipment industry due to its high-quality characteristics, including ordinary machine tools, CNC machine tools, CNC machining centers (vertical, horizontal), etc.

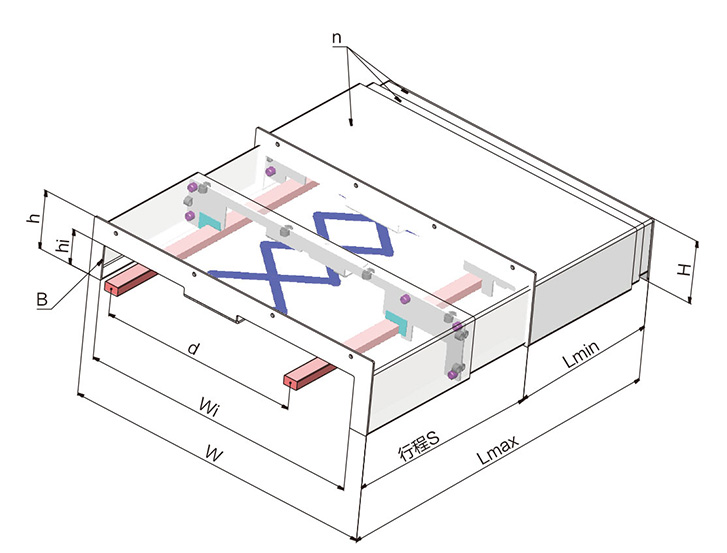

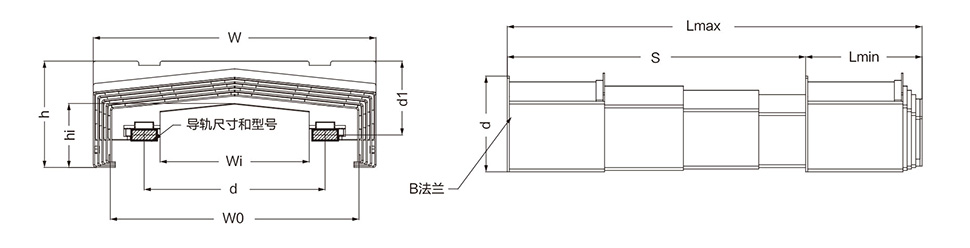

Lmax = Maximum stretch of protective cover

Lmin = minimum compression of the protective cover

S = stroke length

W = outer width of protective cover

Wi = inner width of protective cover

d = center distance of guide rail

h = outer height of protective cover

hi = Inner height of protective cover

H = minimum height

n = number of sections of protective cover

B = Flange at both ends of protective cover

Steel sheet protective cover order parameter table and receipt form

| Parameter code Code |

Parameter name Des |

Parameter Value Figure |

Test result (filled by our company) Test result by Kirus |

Remark Remark |

Description Remark |

|---|---|---|---|---|---|

| Lmax | Stretched out length of protective cover |

Machine travel range ( required) Machine travel range (Not null) |

|||

| Lmin | Protective cover minimum stretched Compressed length |

||||

| S | Shield stroke Travel distance |

Machine maximum distance (optional) Machine max distance (Optional) |

|||

| W | An outer shield width Outer width |

Required Not Not |

|||

| Wi | Width inner shroud Inner width |

Required Not Not |

|||

| WO | Min height |

Optional Optional |

|||

| h | An outer shroud high Outher height |

Required Not Not |

|||

| h1 | Inner shroud high Inner height |

Required Not Not |

|||

| d | Rail center distance Guide rail center distance |

Required Not Not |

|||

| d1 | The distance to the rail end plate The distance from flange to guide rail |

Required Not Not |

|||

| Optional Accessories Accessories need |

Optional Optional |

||||

| Shield material Shield material |

Material / surface treatment (optional ) |

||||

| Type of guide Guide rail item No |

- | Model or size (with photos) (Required Not null / attched) |

|||

Running speed of machine tool |

- | Required Not Not |

|||

| Installation Assemble way |

- | Horizontal / Vertical / Other (Optional) Vertical / horizontal / others (Optional) |

|||

| Installation Machine Model Equipment item No |

- | Optional Optional |

|||

| Use Environment Enviorment |

- | Whether there is a lot of debris (optional) Scrap or not (Optional) |

|||

| Order unit Company name |

Shipping Address Company address |

||||

| Contact Contact way |

Shipping Method Shipping way |

Air Ground Freight Urgent Urgent Other____ |

|||

|

|||||