TAN STAR INDUSTRIES INC.

Products

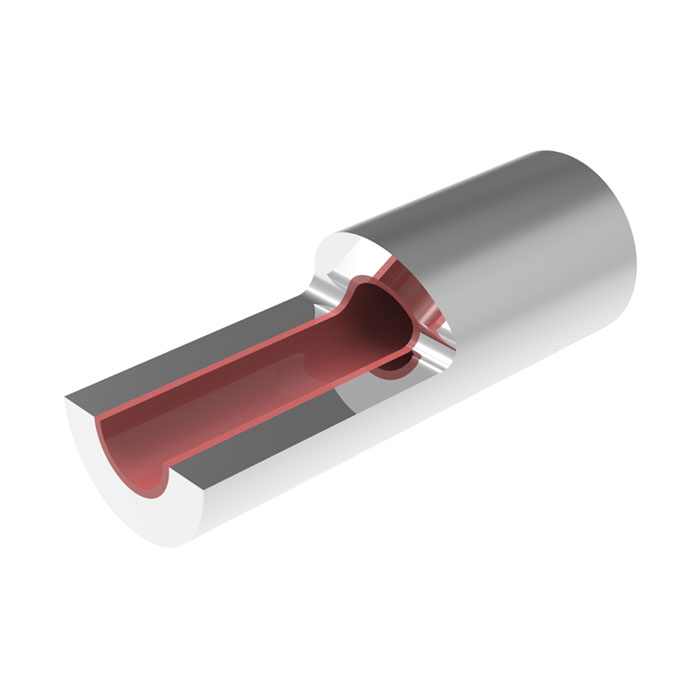

Bimetallic Cylinder

Bimetallic Cylinder

Processing Dimension:

Internal Diameter: Ø14mm to Ø200mm

Maximum Length: 4000mm

Application:

Injection molding. Extrusion molding. Bake-lite molding. Rubber molding

Specification

| T-60 (For Halogen Free) | T-40(TS-A) |

|---|---|

| BEST Cylinder Tan Star T-60 bimetallic cylinder is the best grade nickel basis alloy of Tan Star, the maximum hardness can achieve and over HRC 65. It is special for processing halogen free materials. |

EXCELLENT Cylinder Tan Star T-40 bimetallic cylinder is a kind of nickel basis alloy of Tan Star, and it is include high percentage of tungsten carbide and the hardness can achieve to HRC 65, and it is suitable for processing almost any materials. |

| T-25 (TS-B) | T-10 (TS-C) |

|---|---|

| FUNCTIONALITY Cylinder Tan Star T-25 alloy cylinder is a kind of nickel basis alloy, average hardness is from HRC 56 to HRC 60. It is kind of functionality product for multi-solution. |

FINE Cylinder The hardness of Tan Star T-10 alloy cylinder is around HRC 52-56, and it is suitable for normal corrosive material, and also recycle material of extruder. |

| Model | Base | Process | Average Hardness | Thickness | Glass Fiber |

|---|---|---|---|---|---|

| T-60 (Halogen Free) |

Nickel | Centrifugal Casting | HRc>65 | 1.5-2.0mm | For Halogen-Free |

| T-40 | HRc 60-65 | Under 50% | |||

| T-25 | HRc 56-60 | Under 30% | |||

| T-10 | HRc 52-56 | Under 15% |