Products

Features

Fully automated die or mold changing

High precision die or mold placement

Increased safety and efficiency

Can serve multiple production lines at once

Multiple layout configurations

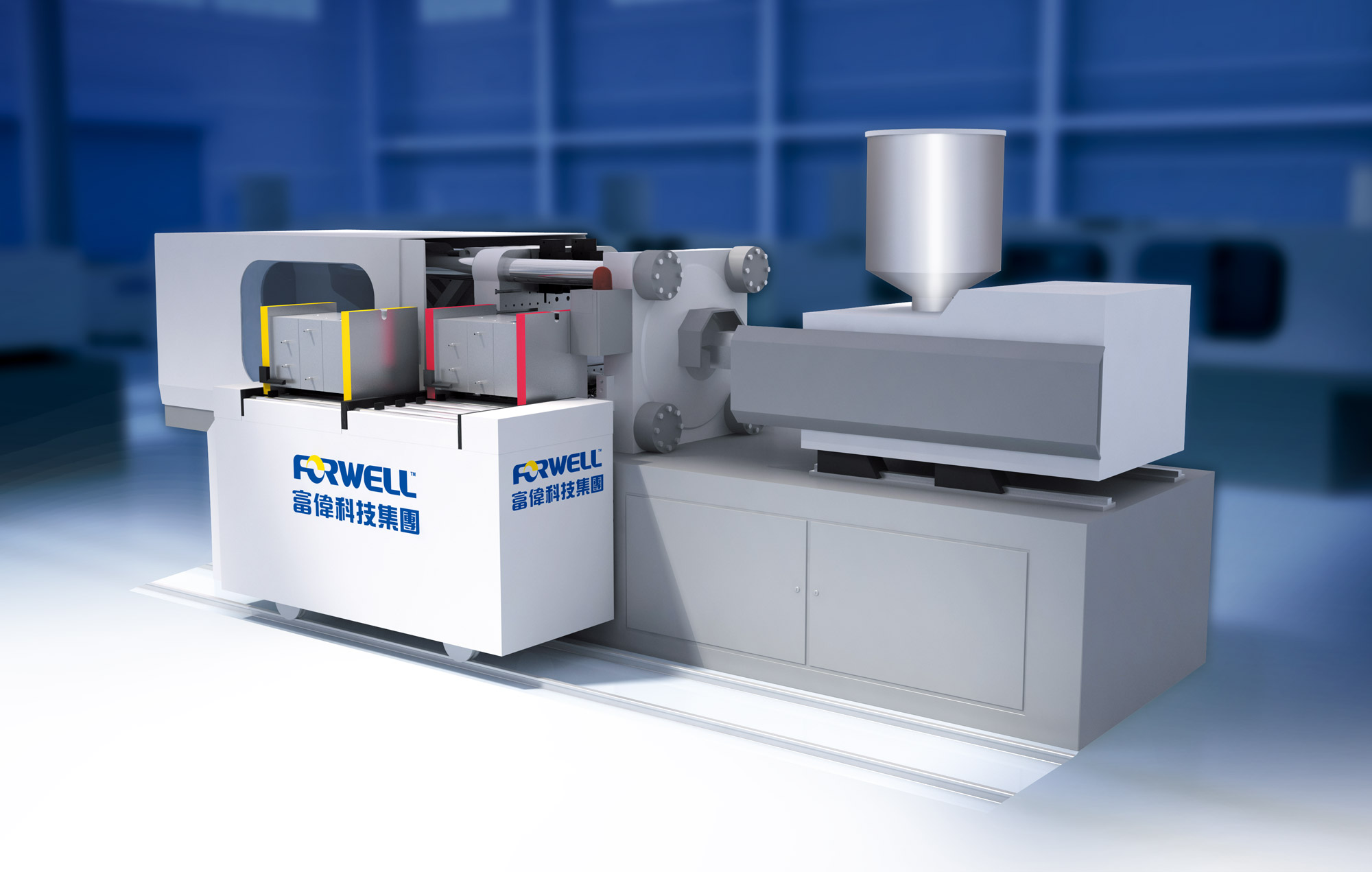

Forwell’s Die Cart / Mold Cart System provides automatic die or mold changes for a range of different machines, such as plastic injection molding machines, plastic extrusion machines and press machines. This Die Cart / Mold Cart system offers very fast, efficient and safe die and mold changes, using an advanced cart on rails system.

Conventional die or mold changes can often take over an hour, but with the Die Cart / Mold Cart System, die or mold changes are automatically completed in just a fraction of the time. Using this system, all procedures from die transfer and changing, to positioning and clamping is carried out by this system, resulting in extremely accurate die or mold changes. As the Die Cart / Mold Cart System offers very precise die or mold changes, many operational issues can be avoided such as locking screws breaking when hand tightened, and incorrect mold alignment resulting in damage to the mold or production equipment.

The Die Cart / Mold Cart System also massively increase safety and efficiency, by allowing for automatic operations and making it feasible to perform many small batch production runs. Another great feature of this system is that it can be configured to specific user needs, different production facilities and serve multiple production lines at once.

Products

Pressure Clamps

Fixed Clamps

Die Cart System Layouts

Depending on whether you require a Die Cart System for a Punch Press or Injection Molding Machine multiple different Cart Layouts are possible. To see which different Cart Layouts are available please first select for which type of machining operation you require a Die Cart System. Remember Forwell can custom build a Die Cart System to fit your machining requirements, whether it be for a single machine or for a whole production line. See below for different examples of Die Cart System Layouts for Mechanical and Hydraulic Type Punch Presses.

Bidirectional Moving Cart Layout

Simultaneous 2-die change operation using two carts either side of the press. This layout allows for the fastest possible die change time.

| Injection Molding Machines | No. of Clamping System | Rollers | Position Hole Size | ||

|---|---|---|---|---|---|

| Weight | Clamping Force | M(mm) | N(mm) | ||

| ~450t | 80t | TFX-10x8 | 60 | 50 | 30 |

| ~550t | 128t | TFX-16x8 | 80 | 50 | 30 |

| ~850t | 128t | TFX-16x8 | 80 | 50 | 30 |

| ~1300t | 200t | TFX-25x8 | 100 | 60 | 38 |

| ~2000t | 320t | TFX-40x8 | 120 | 80 | 40 |

| ~2500t | 320t | TFX-40x8 | 160 | 80 | 40 |

| ~3000t | 320t | TFX-40x8 | 180 | 80 | 40 |