Products

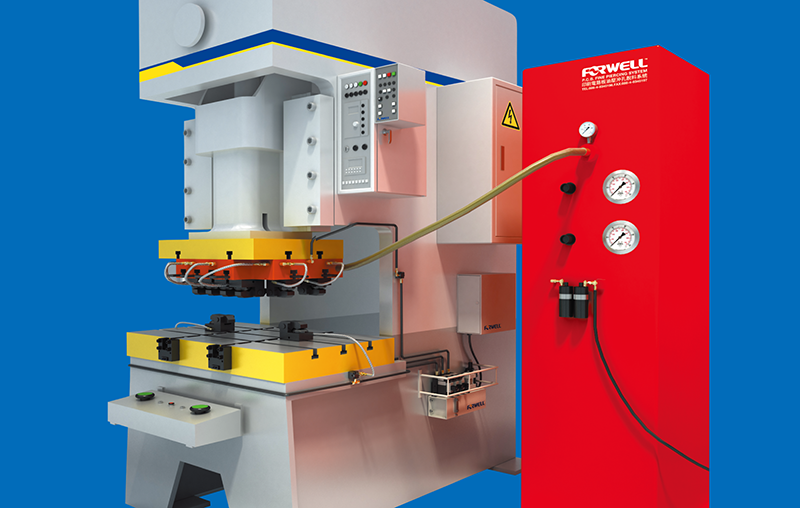

PCB Fine Piercing System

Features

High precision, quality and durability

Easy operation and maintenance

Suitable for fine piercing of high-density printed circuit boards

Decreased die change time

Automatic system, reducing labor costs

Introduction

Forwell’s PCB Fine Piercing Systems combine a hydraulic power unit charged with air pressure, a piercing plate and a quick die change system. This system uses hydraulic pumps to activate the pressing operation, either using automatic or manual control. Also due to the hydraulic power unit, this system is very energy efficient and highly reliable, and with its simple structure easy maintenance is ensured.

Moreover with this system easy adjustments can be made to the operating pressure according to the PCB material and specifications, generating efficient pressing and excellent results. Additionally these systems are perfect for high quality, high accuracy piercing and stripping of PCB’s, and with a quick die change system, increased productivity is guaranteed.

Products

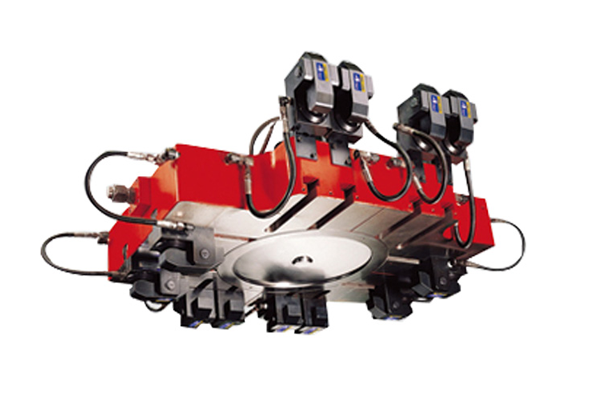

Piercing Plate Unit

TY Die Clamp

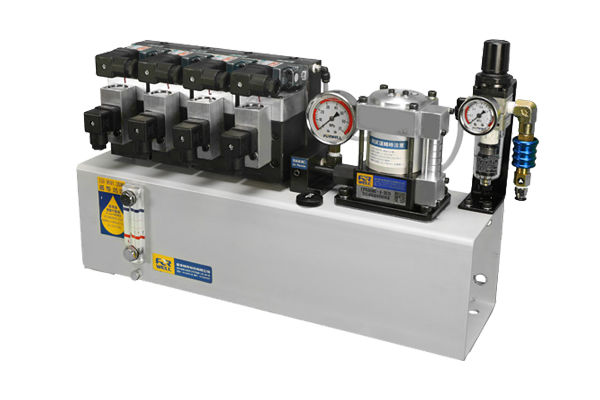

Power Unit

Pump Unit

System Selection

Forwell’s PCB Fine Piercing System is available in a range of different models to suit your PCB Piercing and Stripping operations. Please view the table below to select a suitable model depending on the required press tonnage and stripping force.

| Press Tonnage | Model | Stripping Farce | Hold-down Farce |

|---|---|---|---|

| 60 ~ 80TON | FP-2 | 35.0tf Max. | 16.0tf Max. |

| FP-2L | |||

| 80 ~ 110TON | FP-3 | 43.0tf Max. | 21.0tf Max. |

| FP-3L | |||

| 110 ~ 150TON | FP-5 | 45.0tf Max. | 24.0tf Max. |

| FP-5L | |||

| 150 ~ 200TON | FP-7 | 63.0tf Max. | 36.0tf Max. |

| FP-7L | |||

| 200 ~ 350TON | FP-8 | 100.0tf Max. | 50.0tf Max. |