Products

Full automatic processing:

Rough grinding

Dressing

Precise grinding

High accuracy, easy operation

X, Y, Z axis feeding system

The main structure is X, Y, Z axis feeding system which are work head, internal grinding head and exteral grinding head.

The feature is X, Y, Z axis servo transmission or 2axis (XY, XZ) move simultaneously in order to reach high precision grinding process requirement.

This machine adopts oil-water separation and high-rigid box structure designed,non assembling tolerance,high rigidity. The lubrication oil and coolant is separated to collect from outside the machine,in order to eliminate vibratory and hea,t increase the efficiency of oil collection,to enhance the cooling effect and increase stability.

- Plunge type Internal External grinding

- Plunge type External grinding

Forming wheellnternal grinding

Work Head Spindle

- The cartridge spindle in work head is supported by P4-class precision double roller and angular contact ball bearing.

- The work head can be adjusted angle +15° and -15° ,it is suitable for internal and external taper grinding. Or can choose

a. Manual rotating angle type,for grinding internal and external of cylindrical and taper

b. Automatic rotating type (B axis) (X,Y,Z,B) (optional),for grinding internal and externa

c. Angle positioning control type (C axis) (X,Y,C、X,Z,C) (optional),for grinding cam or eccentric hole - It is to shorten grinding time,improve grinding accuracy and expansion grinding field.

- Y,Z axis adopts UP class roller linear guide-way,automatic forced lubrication system and oil cooler system.

- External,internal wheel use high speed,high precision and low vibration motor.

- Y,Z axis wheel spindle can be chose optional build-in type spindle,high speed and small vibration can be reached high accuracy workpiece after grinding.

External grinding horizontal feeding system,Yaxis

Internal grinding horizontal feeding system,Z axis

B axis for JHD-3205 series only

- This is high accuracy rotary table with the design of double leads and bearings, it is suitable for heavy grinding procedure and continuous process.

- Occlusion area reaches 35%~45%.

- Good abrasion resistance, no need to adjust backlash within 2 years.

- Keep accuracy within 0.003.

- Repeated positioning accuracy can be reached 0.001. It satisfies fast positioning grinding requirement.

External grinding horizontal feeding system Y axis.

External internal grinding horizontal feeding system, Y/ Z axis.

- Y, Z axis adopts UP class roller linear guide-way, automatic forced lubrication system and oil cooler system.

- Direct drive servo motor transmission, C1 class double pre-tensioned ball screws and P4 class angel contact ball bearing and 0.05μ/m high-resolution linear scale.

- External, internal wheel use high speed, high precision and low vibration motor.

- Y,Z axis wheel spindle can be chose optional build-in type spindle, high speed and small vibration can be reach high accuracy workpiece after grinding.

Applicable industries

This machine is designed for motor vehicles and other transportation, energy, precision machine tool components, air / hydraulic components , precision measuring instruments, electronic/ optical instruments.

This machine adopts oil-water separation and high-rigid box structure designed, high rigidity. The lubrication oil and coolant is separated to collect from outside the machine, in order to eliminate vibratory and heat increase the efficiency of oil collection, to enhance the cooling effect and increase stability.

The main structure is X, Y, Z axis feeding system, they are work head, internal grinding head and external grinding head, the feature is X, Y, Z 3axes servo transmission or 2 axes (X, Y) (X, Z) move simultaneously, in order to reach high precision and complicated workpiece grinding process requirement.

X, Y, Z axis feeding system uses high precision roller linear guide-way and double pre –tension ball screws. The repeated positioning accuracy is through servo motor, high precision ball screw, roller linear guide-way, angular contact ball bearing , coupling and automatic forced lubrication system. All axes slider adopt high precision roller linear guide-way, high precision and long service life features. All sliding and rotating parts uses automatic forced lubrication, to ensure optimal machine life and accuracy.

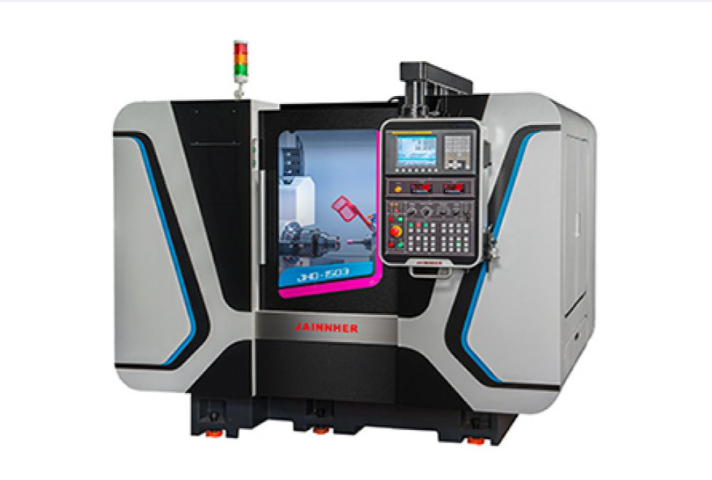

| MODELS | ITEMS | JHD-1503IO External& Internal |

|

| Capacity | ID (Hole, Depth) | Ø 6~Ø 120 x 80mm Ø 2~Ø 6 (opt) |

|

|---|---|---|---|

| Max. grinding dia. | Ø150 mm(5.9") | ||

| Max. ID depth / OD length | ID:100/OD:120mm | ||

| Max. swing over | Ø 300 mm | ||

| Max. job weight | 70kgs(154lbs)100kgs(220lbs)OPT | ||

| Type of wheel head | OD, ID | ||

| Work Head X Axis |

Chuck | 6” | |

| Spindle rpm | 20-1000 rpm/min(variable speed) | ||

| Max. stroke | 350 mm(13.7") | ||

| Swing angle | - | ||

| Rapid speed | 10 m/min (32.8ft/min) | ||

| Min. Setting unit | 0.001mm (0.00004”) | ||

| Y Axis | OD wheel size | Ø 150 x 25 mm | |

| Wheel rpm | 4200 rpm | ||

| Max. stroke | 350 mm(13.7") | ||

| Rapid speed | 10m/min (32.8ft/min) | ||

| Min. setting unit | 0.001 mm(0.00004”) | ||

| Z Axis | ID wheel size | Depends | |

| Wheel rpm | Depends | ||

| Max. stroke | 350 mm(13.7") | ||

| Rapid speed | 10 m/min(32.8ft/min) | ||

| Min. setting unit | 0.001 mm(0.00004”) | ||

| Motor | X axis | FANUC β8 1.2 kw | |

| Work head spindle | FANUC β12 1.4 kw | ||

| Y axis | FANUC β8 1.2 kw | ||

| Y axis spindle | 2.2 kw (3HP) 2P V3 | ||

| Z axis | FANUC β8 1.2 kw | ||

| Z axis spindle | 2.2 kw (3HP) 2P V3 | ||

| Lubrication pump | 0.18 kw ( 0.25HP ) 4P | ||

| Hydraulic pump | 0.75 kw (1HP) 4P | ||

| Coolant pump | 0.18 kw ( 0.25HP ) 4P | ||

| Machine | Net weight | 3800kgs | |

| Gross weight | 4200kgs | ||

| Floor space | 2800 x 1950 x 2100 mm | ||

| * All specifications are subject to change without notice. | |||