Products

Controlled by CNC, while the table moves up, the tool rotates simultaneously to cut helical shape. This machine is made with 10 ton force and 1500 stroke. Mitsubishi human-machine interface is equipped as standard, it can be changed to FANUC as per customer’s requirement.

The operator can stand on the ground to load the workpiece without stairs. Comparing with hydraulic broaching machines, the size of the table-up broaching machine is smaller, there is no power consumption when the machine is idle. Different tools and workpieces can be managed separately in the human-machine interface.

Categories Automobile industry, CNC Helical Broaching Machine - AXISCO

The auto broach lifter, auto tool cleaner, fixture, and chip conveyor are standard accessories. Optional accessories such as broach tools, & amp; auto loading/ unloading mechanism can be customized according to your requirement…

Broaching is a technology to cut complicated shape in one pass. The coordination of the machine, the tooling, & amp; the fixture is crucial for making high precision products. Based on over 30 years of experience, Axisco commited itself as a turn-key broaching solution provider. Whether you are an expert or new to broaching, it is always simple to broach products in world-class quality on the machines made by Axisco.

When sending an inquiry, please provide before & amp; after broaching drawings, we will suggest the most suitable model to you.

Why choose Axisco?

It is recognized by the customers in more than 30 countries worldwide and has more than 35 years of experience. Our customers are all over the aerospace, automobile, gear, bicycle, hand tools, locks, hydraulic valve parts, electronic parts, and various hardware industries. We have a complete broaching solution, including CNC helical broaching machines, servo broaching machines, hydraulic internal broaching machines, and hydraulic external broaching machines. Machines are in different tonnages and different strokes according to customer needs. The professional team can quickly respond to various customized mechanisms, fixtures, tools, and automation integration needs.

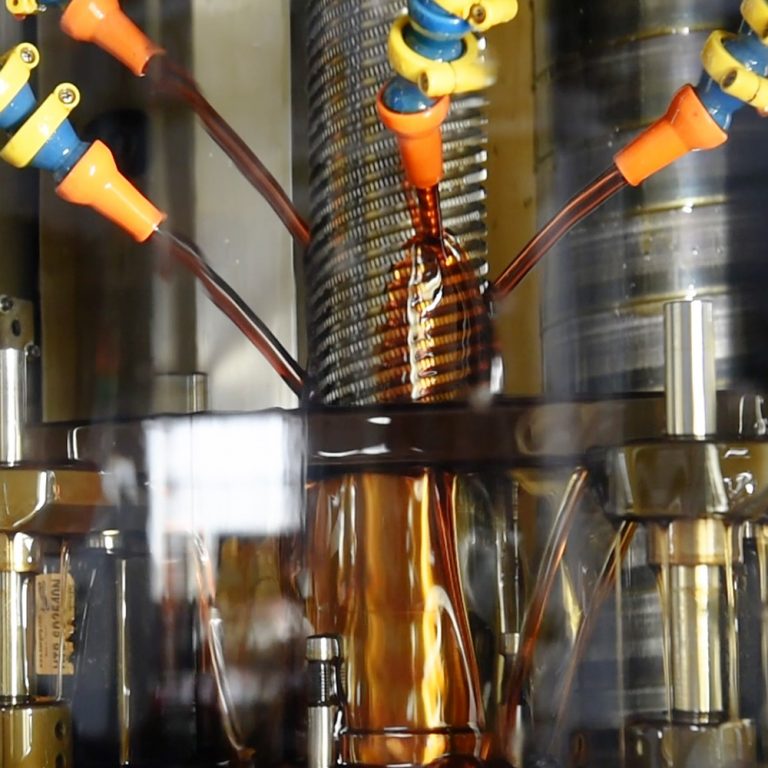

While the table moves up, the tool rotates simultaneously to cut helical shape. All helical teeth are cut at once.

Full electromechanical machine with smart PC-based interface.

Operator can stand on the ground to load the workpiece. No need for stairs or digging a pit.

Broach is holded from top during broaching, the cutting vibration is reduced which result in better precision.

Size and height are smaller than hydraulic broaching machine

The broach tool lifting and cleaning are done automatically.

Autoloading/unloading device is available.

| MODEL | CHX-1015 | CHX-1516 | CHX-2016 | |

|---|---|---|---|---|

| No. of station | 1 | 1 | 1 | |

| Broaching force | tom | 10 | 15 | 20 |

| Max. stroke | mm | 1500 | 1600 | 1600 |

| Helix angle | ° | 0~30 | 0~30 | 0~30 |

| Broaching speed(60Hz) | m/min | 10 | 10 | 10 |

| Return speed(60Hz) | m/min | 24 | 24 | 24 |

| Max. workpiece size | mm | ø225 | ø225 | ø300 |

| Working table height | mm | 1072 | 1225 | 1300 |

| Main power | kw | 11 | 15 | 30 |

| CNC controller | Mitsubishi | Mitsubishi | Mitsubishi | |

| Machine height | mm | 3853 | 4446 | 4700 |

| Floor dimemsion | mm | 1600*2680 | 2030*2654 | 2100*2500 |

* The specification is for reference only. All rights are reserved by axisco.