Products

CHI-2516 internal broaching machine. With a 25 ton broaching force, 1600mm stroke, it is suitable for internal broaching or keyway broaching in large workpieces. It can produce 1 to 3 workpieces within 40 seconds of processing.

Categories Automobile industry, Hydraulic Internal Spline Broaching Machine - AXISCO

It is used for internal keyway or spline broaching.

Finish complicated shape in one pass to save machining time.

Precise location, fast cutting, with high precision.

Rigid machine body design.

Over 30 years of experience in tooling & fixture design.

Stepless adjustment in pressure and speed.

Auto tool cleaning (optional)

Autoloading/unloading device. (optional)

It can be designed into 1 to 3 stations according to quantity requirement.

CE (optional)

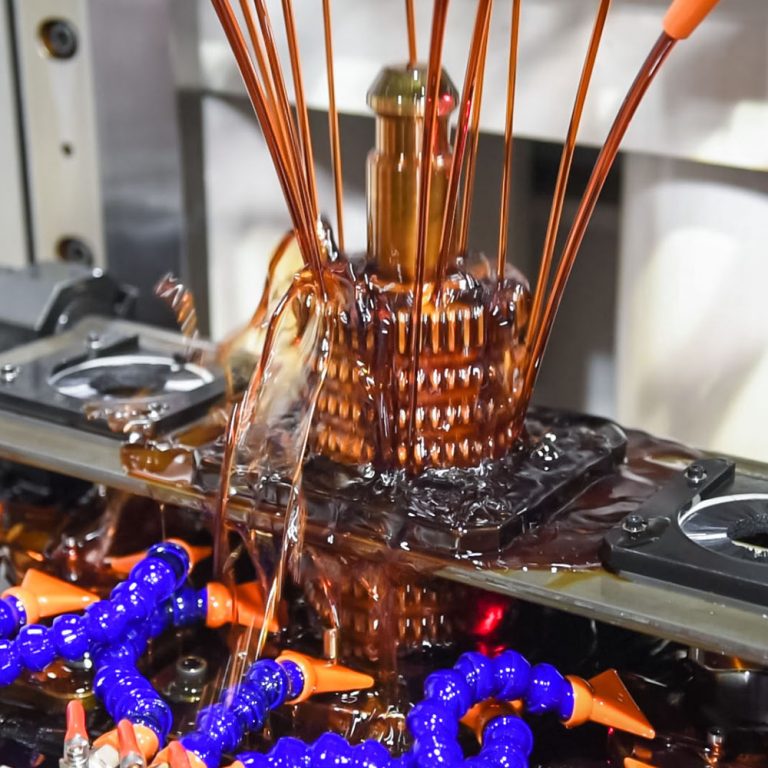

The picture below is from a customer in the gear industry. The product is for automobile transmissions. The accuracy level of the processed gear is DIN7. Two years after the delivery of the machine, when we revisited the customer’s factory. The customer was delighted with the equipment and proceeded with a second order.

The optional devices ordered by this customer:

-

Three station

-

Auto broach lifter

-

Auto tool cleaning device

-

Extended magnetic chip conveyor

-

Hydraulic oil chiller

-

Coolant chiller

The internal broaching machine is suitable for large-scale processing. A broach is used with the device to complete the workpiece’s internal profile or keyway at one time. It is commonly used in hand tools, hardware parts, or parts with complex shapes in the automotive and aerospace industry for its short processing time with high precision. Axisco can customize fixtures, tools, tool holders, etc., to fulfill different needs.

The machines’ main structure has been elaborately processed, and the key parts are hand-scraped. The mechanical design, hardware assembly, control system assembly, and software writing are all completed in our hands, and strict quality control is carried out throughout the process.

| MODEL | CHI-0306/0308/0310 | CHI-0508/0510/0512 | CHI-0810/0813 | CHI-1010/1013/1015 | CHI-1513/1515 | CHI-2015/2018 | |

|---|---|---|---|---|---|---|---|

| Broaching force | ton | 3 | 5 | 8 | 10 | 15 | 20 |

| Max. stroke | mm | 600/800/1000 | 800/1000/1200 | 1000/1300 | 1000/1300/1500 | 1300/1500 | 1500/1800 |

| Broaching speed(60Hz) | m/min | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 |

| Return speed(60Hz) | m/min | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Max. workpiece size | mm | ø300 | ø300 | ø350 | ø420 | ø460 | ø550 |

| Working table height | mm | 1816 | 2266 | 2313 | 2713 | 2910 | 2685 |

| Working table area | mm | 360*500 | 380*600 | 400*700 | 450*800 | 480*900 | 600*960 |

| Main power | kw | 3.8(5hp) | 5.6(7.5hp) | 7.5(10hp) | 11.3(15hp) | 18.8(25hp) | 30(40hp) |

| Machine height/Lifter | mm | 2500/3166 | 3371/4153 | 3532/4407 | 4097/4530 | 4915/5390 | 4164/4700 |

| Floor dimension | mm | 1150*1350 | 1300*1550 | 1400*1900 | 1600*1800 | 1720*2000 | 1900*2280 |

* The specification is for reference only. All rights are reserved by axisco.