Products

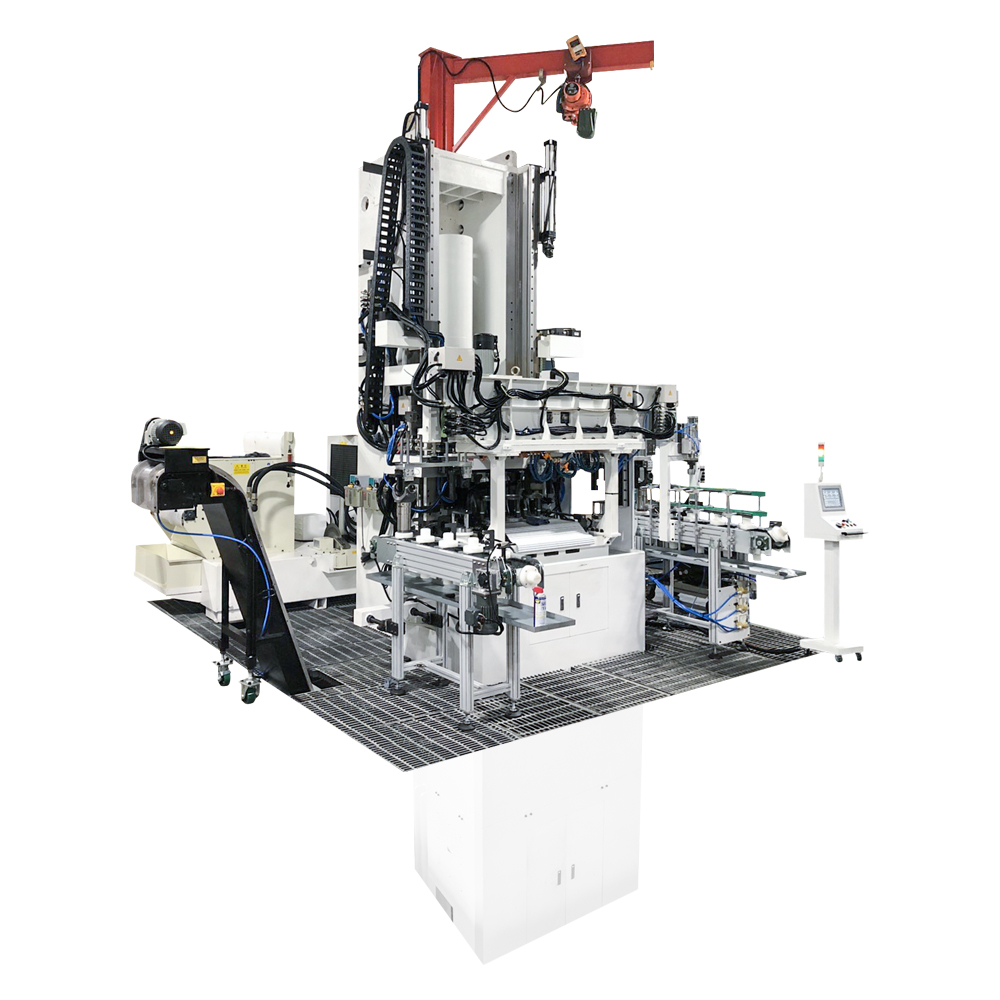

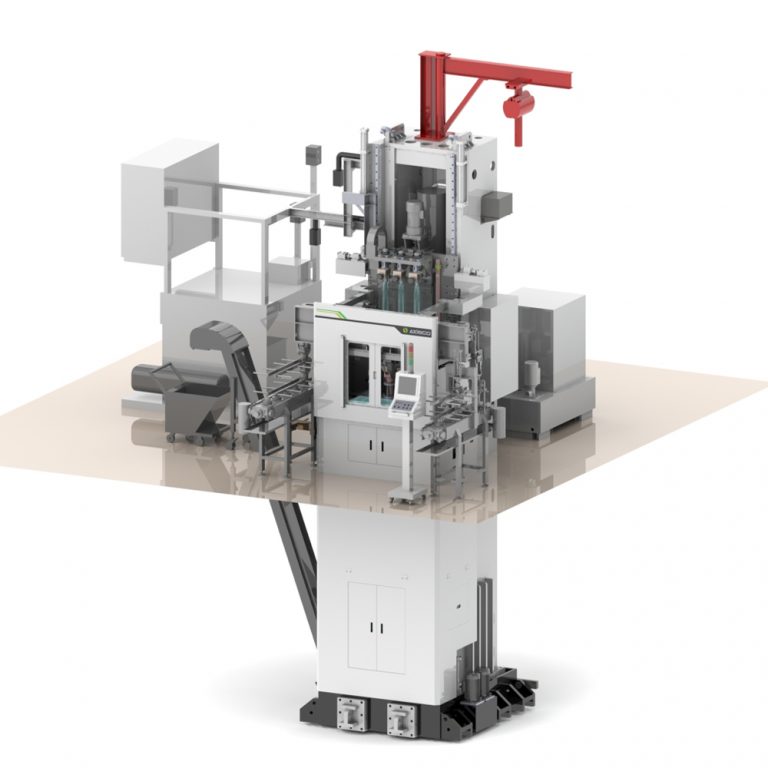

With 80 ton broaching force and 2200 mm stroke, which is suitable for making internal spline or keyway.

A variety of customized devices are available according to customer’s requirements. Such as auto broach lifter, the broach cleaner, fixtures, broach tools, & auto loading/ unloading mechanism.

Broaching is a technology to cut complicated shape in one pass. The coordination of the machine, the tooling, & the fixture is crucial for making high precision products. Based on over 30 years of experience, Axisco commited itself as a turn-key broaching solution provider. Whether you are an expert or new to broaching, it is always simple to broach products in world-class quality on the machines made by Axisco.

When sending an inquiry, please provide before & after broaching drawings, we will suggest the most suitable model to you.

Categories Automobile industry, Hydraulic Internal Spline Broaching Machine - AXISCO

‧ It is used for internal keyway or spline broaching.

‧ Finish complicated shape in one pass to save machining time.

‧ Precise locationing, fast cutting, with high precision.

‧ Rigid machine body design.

‧ Over 30 years of experience in tooling & fixture design.

‧ Stepless adjustment in pressure and speed.

‧ Auto tool cleaning (optional)

‧ Auto loading/unloading device. (optional)

‧ It can be designed into 1 to 3 station according to quantity requirement.

‧ CE (optional)

A Short Story about Installation and Remote Connection

A few months ago, we installed a new broaching machine at a big transmission parts manufacturing group. The group has factories in many cities. The factory we visited has more than ten broaching machines and thousands of broach tools which are allied in hundreds of transmission parts.

While completing the installation, our engineer requests the customer to provide their laptop for installing the necessary software to remotely link to the machine through it. The customer asked, “What are the advantages of doing this?” We replied that if they need us to check the machine or update the software in the future, we can link to it immediately instead of traveling for several days. It is a way to save lots of time and cost for both parties.

After we went back, the customer asked to change some of the terms on the interface according to their operators’ habits. It took only less than 30 minutes for updating and testing the program remotely. In the past, you might not ask your supplier to travel a long way to change two or three words. However, with our remote service, these fine tunes become possible.

| MODEL | CHI-0306/0308/0310 | CHI-0508/0510/0512 | CHI-0810/0813 | CHI-1010/1013/1015 | CHI-1513/1515 | CHI-2015/2018 | |

|---|---|---|---|---|---|---|---|

| Broaching force | ton | 3 | 5 | 8 | 10 | 15 | 20 |

| Max. stroke | mm | 600/800/1000 | 800/1000/1200 | 1000/1300 | 1000/1300/1500 | 1300/1500 | 1500/1800 |

| Broaching speed(60Hz) | m/min | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 |

| Return speed(60Hz) | m/min | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 | 2~12 |

| Max. workpiece size | mm | ø300 | ø300 | ø350 | ø420 | ø460 | ø550 |

| Working table height | mm | 1816 | 2266 | 2313 | 2713 | 2910 | 2685 |

| Working table area | mm | 360*500 | 380*600 | 400*700 | 450*800 | 480*900 | 600*960 |

| Main power | kw | 3.8(5hp) | 5.6(7.5hp) | 7.5(10hp) | 11.3(15hp) | 18.8(25hp) | 30(40hp) |

| Machine height/Lifter | mm | 2500/3166 | 3371/4153 | 3532/4407 | 4097/4530 | 4915/5390 | 4164/4700 |

| Floor dimension | mm | 1150*1350 | 1300*1550 | 1400*1900 | 1600*1800 | 1720*2000 | 1900*2280 |

* The specification is for reference only. All rights are reserved by axisco.