Products

Surface Grinding Machine

Construction and Features

All structural parts are manufactured from high quality meehanite cast iron, tempered for stress relief and high rigidity.

The column is rib reinforced combined with increased wall thickness on base, ensuring extra high rigidity and grinding.

Model Identification

CB-618 -V- Manual Surface Grinder

CB-618M Steel Ball Manual Surface Grinder

CB-1A618 Single Axis Automatic Surface Grinder

CB-2A618 Two Axis Automatic Surface Grinder

CB-3A618 Two Axis Automatic Surface Grinder (with Rapid Vertical Traverse)

CB-618ASD Three Axis Automatic Surface Grinder (Home Point Reset)

Table hand

Table hand wheel on manual model for controling table direction.

CB-618 Saddle and Table slideways

The slideways on this model are "v" and flat structure, scraped for extremely smooth movement and outstanding accuracy.

CB-618M Saddle and Table slideways

The slideways on this model are equipped with high precision slide guides with steel balls, featuring maximum smoothness for table feed and long service life.

Cross and vertical Feed Micrometric Adjustment

The worm is manufactured from medium carbon steel, hardened and precision ground combimed with phosphor bonze worm gear for smooth transmission, minimun wear and high accuracy (0.001mm)

Superior Rigidity and construction

Double "v" shaped slide ways between the saddle and base. Slideway surfaces are coated with Teflon and precision scraped, assuring extremely smooth movement and outstanding accuracy.

機身與主軸座滑動面採硬化處理及精密研磨之滑軌。

| MODEL | CB-618 | CB-1A618 | CB-2A618 | CB-3A618 |

| CB-618M | CB-618ASD | |||

| Capacity | ||||

| Table sizes | 150x460mm | 150x460mm | 150x460mm | 150x460mm |

| Longitudinal travel | 480mm | 480mm | 480mm | 480mm |

| Cross travel | 170mm | 170mm | 170mm | 170mm |

| Spindle center to table surface | 460mm | 460mm | 460mm | 460mm |

| Magnetic chuck sizes | 150x450mm | 150x450mm | 150x450mm | 150x450mm |

| Longitudinal Feed | ||||

| Manual travel | 530mm | 530mm | 530mm | 530mm |

| Automatic travel | -- | 510mm | 510mm | 510mm |

| Table traverse rate | -- | 5~25M/min | 5~25M/min | 5~25M/min |

| Cross Feed | ||||

| Manual travel | 180mm | 180mm | 180mm | 180mm |

| Automatic travel | -- | -- | 170mm | 170mm |

| Automatic feed (variable) | -- | -- | 0.5~10mm | 0.5~10mm |

| Hand wheel per revolution | 5mm | 5mm | 5mm | 5mm |

| Hand wheel per graduation | 0.02mm | 0.02mm | 0.02mm | 0.02mm |

| Micrometric adjustment par revolution | 0.2mm | 0.2mm | 0.2mm | 0.2mm |

| Micrometric adjustment par graduation | 0.001mm | 0.001mm | 0.001mm | 0.001mm |

| Vertical Feed | ||||

| Hand wheel per revolution | 1mm | 1mm | 1mm | 1mm |

| Hand wheel per graduation | 0.005mm | 0.005mm | 0.005mm | 0.005mm |

| Micrometric adjustment par revolution | 0.2mm | 0.2mm | 0.2mm | 0.2mm |

| Micrometric adjustment par graduation | 0.001mm | 0.001mm | 0.001mm | 0.001mm |

| Automatic feed (ASD) |

-- |

-- | 0.001~0.099mm | |

| Grinding Wheel | ||||

| Grinding wheel sizes | 203x12~ 19x31.75mm |

203x12~ 19x31.75mm |

203x12~ 19x31.75mm |

203x12~ 19x31.75mm |

| Spindle speed (rpm) | 3450(60hz)/ 2850(50hz) |

3450(60hz)/ 2850(50hz) |

3450(60hz)/ 2850(50hz) |

3450(60hz)/ 2850(50hz) |

| Motor | ||||

| Spindle motor | 2HP | 2HP | 2HP | 2 HP |

| Hydraulic motor | -- | 1HP | 1 HP | 1 HP |

| Gross feed drive | -- | -- | 10W | 40W |

| Vertical feed drive | -- | -- | -- | 1/5 HP |

| Weight | ||||

| Net wet (Approx) | 740kgs | 825hgs | 830 kgs | 840 kgs |

| Gross weight (Approx) | 840kgs | 925kgs | 930 kgs | 940 kgs |

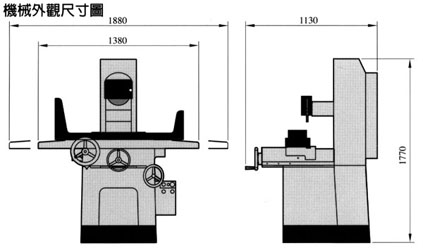

| Packing Dimensions ( LxWxH ) |

1480x1120x1950 mm |

1480x1120x1950 mm |

1480x1120x1950 mm |

1480x1120x1950 mm |

| Total Rated Horsepower | 3.0HP | 4.0HP | 4.5 HP | 5.0 HP |

| Above information are for reference only, The machine design, specifications and construction are subject to change without prior notice. | ||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||