Products

Surface Grinding Machine

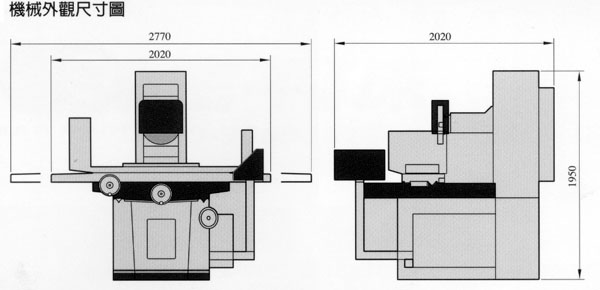

CB-3060 ASD Three Axes Fully Automatic Surface Grinding Machine

Automatic vertical feed is driven by a stepping motor. Once the set value for automatic grinding finished, grinding wheel stops feeding, then performs polishing, when polishing finished, table stops automatically and the grinding wheel returns to the home point.

CB-3060 3A Hydralilic Precision Surface Grinding Machine

Automatic longitudinal and cross feed with rapid vertical traverse.

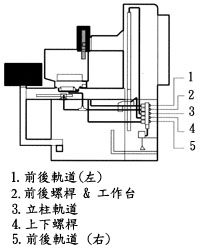

Construction and Features

The major structural parts are manufactured form high quality cast iron, featuring high rigidity, deformation-free and maximum stability.

All slideways are precision scraped and coated with wear-resistant media for extremely smooth motion and lifetime accuracy.

The spindle has a labyrinth circulation design, and is water-resistant and dust-resistant. The wheel flange and spindle is properly assembled to prevent coolant from entering into the spindle service life.

The vertical feed is powered by a motor, permitting rapid traverse to imcrease efficiency.

The cross feed is transmitted through precision ball screw, and driven by a special motor to assure maximum smoothness of movement.

The double-unit type automatic lubrication system provides for minimized parts wear while ensuring the machining accuracy.

All switches are centralized on a control panel, which is mounted on a pendant arm for convenient operation and avoiding coolant entering.

Setting Automatic Grinding on ASD Models

- Feed times 1~99 times

- Feed each time (0.001~0.099mm)

- polish grinding ( 1~10 times )

Automatic Lubrication System

- Employs double pumps to perform continuous lubrication, during operation, all slideways are lubricated automatically for extending the machine service life.

- Extra large lubrication oil tank provides effective cooling for heat generated by movement friction, and oil is recirculated.

Cross Movement Adjustment

- The double knobs combined with ergonmical principle design provides added adjustment convenience and operation smoothness.

- The built-in switch box not only protects the electronic components, but also prevents coolant from entering.

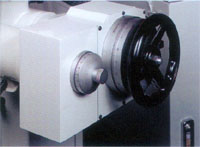

Elevation Transmission

- The large graduated collar is easy to read. The micrometric adjustment device is easy to operate with graduation in 0.001 (0.005").

Cross Feed Transmission and Fluid Return

- The cross feed is transmitted through a high precision ball screw, assuring high accuracy of feeding and smooth movement.

- The centralzed return flow design for grinding fluid on base facilitate cleaning and maintenance.

Column and Saddle

- The column is an oversized structure with increased high, The honeycomb type high rigidity structure may reduce resonance to a minimum while upgrading stability in heavy duty machining.

- Powerful 7.5HP spindle motor provides added grinding capability and high efficienty.

- The fluid return tank for the saddle is increased in depth and width, allowing for smooth fluid return without dust deposit problem.

- The slideways on table and saddle are designed with a labyrinth shape. It prevents cutting fluid from entering into the machine and ensures the machine life and and machining quality.

| MODEL | CB-3A3060 | CB-3060ASD |

| Capacity | ||

| Table sizes | 300x650mm | 300x650mm |

| Longitudinal travel | 680mm | 680mm |

| Cross travel | 320mm | 320mm |

| Spindle center to table surface | 600mm | 600mm |

| Magnetic chuck sizes | 300x600mm | 300x600mm |

| Longitudinal Feed | ||

| Manual travel | 750mm | 750mm |

| Automatic travel | 700mm | 700mm |

| Table traverse rate | 5~25M/min | 5~25M/min |

| Cross Feed | ||

| Manual travel | 350mm | 350mm |

| Automatic travel | 310mm | 310mm |

| Automatic feed (variable) | 0.5~10mm | 0.5~10mm |

| Hand wheel per revolution | 5mm | 5mm |

| Hand wheel per graduation | 0.02mm | 0.02mm |

| Micrometric adjustment par revolution | 0.2mm | 0.2mm |

| Micrometric adjustment par graduation | 0.001mm | 0.001mm |

| Vertical Feed | ||

| Hand wheel per revolution | 1 mm | 1 mm |

| Hand wheel per graduation | 0.005 mm | 0.005 mm |

| Micrometric adjustment par revolution | 0.2mm | 0.2mm |

| Micrometric adjustment par graduation | 0.001mm | 0.001mm |

| Automatic feed (ASD) | -- | 0.001~0.099mm |

| Grinding Wheel | ||

| Grinding wheel sizes | 355x50x127 mm | 355x50x127 mm |

| Spindle speed (rpm) | 1720(60hz)/1425(50hz) | 1720(60hz)/1425(50hz) |

| Motor | ||

| Spindle motor | 7.5 HP | 7.5 HP |

| Hydraulic motor | 3 HP | 3 HP |

| Gross feed drive | 1/5 HP | 1/5 HP |

| Vertical feed drive | 1/5 HP | 1/5 HP |

| Weight | ||

| Net wet (Approx) | 2400 kgs | 2400 kgs |

| Gross weight (Approx) | 2650 kgs | 2650 kgs |

| Packing Dimensions ( LxWxH ) | 2240x2160x2240mm | 2240x2160x2240mm |

| Total Rated Horsepower | 11 HP | 11 HP |

| Above information are for reference only, The machine design, specifications and construction are subject to change without prior notice. | ||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||