Products

MULTI CAVITY HOT RUNNER

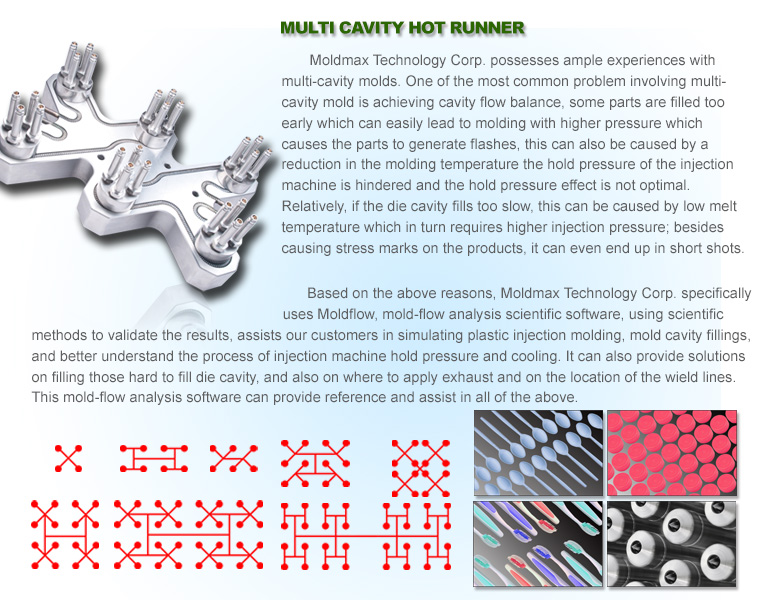

Moldmax Technology Corp. possesses ample experiences with multi-cavity molds. One of the most common problem involving multi-cavity mold is achieving cavity flow balance, some parts are filled too early which can easily lead to molding with higher pressure which causes the parts to generate flashes, this can also be caused by a reduction in the molding temperature the hold pressure of the injection machine is hindered and the hold pressure effect is not optimal. Relatively, if the die cavity fills too slow, this can be caused by low melt temperature which in turn requires higher injection pressure; besides causing stress marks on the products, it can even end up in short shots.

Based on the above reasons, Moldmax Technology Corp. specifically uses Moldflow, mold-flow analysis scientific software, using scientific methods to validate the results, assists our customers in simulating plastic injection molding, mold cavity fillings, and better understand the process of injection machine hold pressure and cooling. It can also provide solutions on filling those hard to fill die cavity, and also on where to apply exhaust and on the location of the wield lines. This mold-flow analysis software can provide reference and assist in all of the above.