Products

VALVE GATE SYSTEM

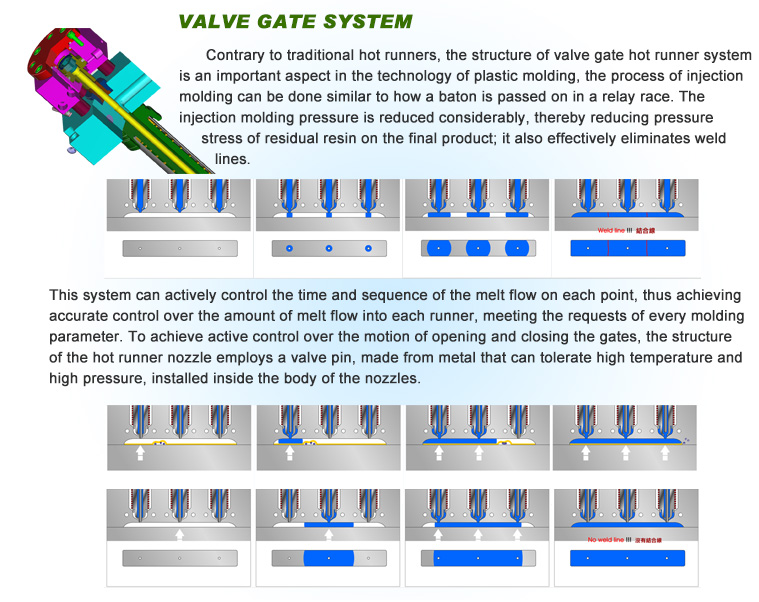

Contrary to traditional hot runners, the structure of valve gate hot runner system is an important aspect in the technology of plastic molding, the process of injection molding can be done similar to how a baton is passed on in a relay race. The injection molding pressure is reduced considerably, thereby reducing pressure stress of residual resin on the final product; it also effectively eliminates weld lines.

This system can actively control the time and sequence of the melt flow on each point, thus achieving accurate control over the amount of melt flow into each runner, meeting the requests of every molding parameter. To achieve active control over the motion of opening and closing the gates, the structure of the hot runner nozzle employs a valve pin, made from metal that can tolerate high temperature and high pressure, installed inside the body of the nozzles.