Products

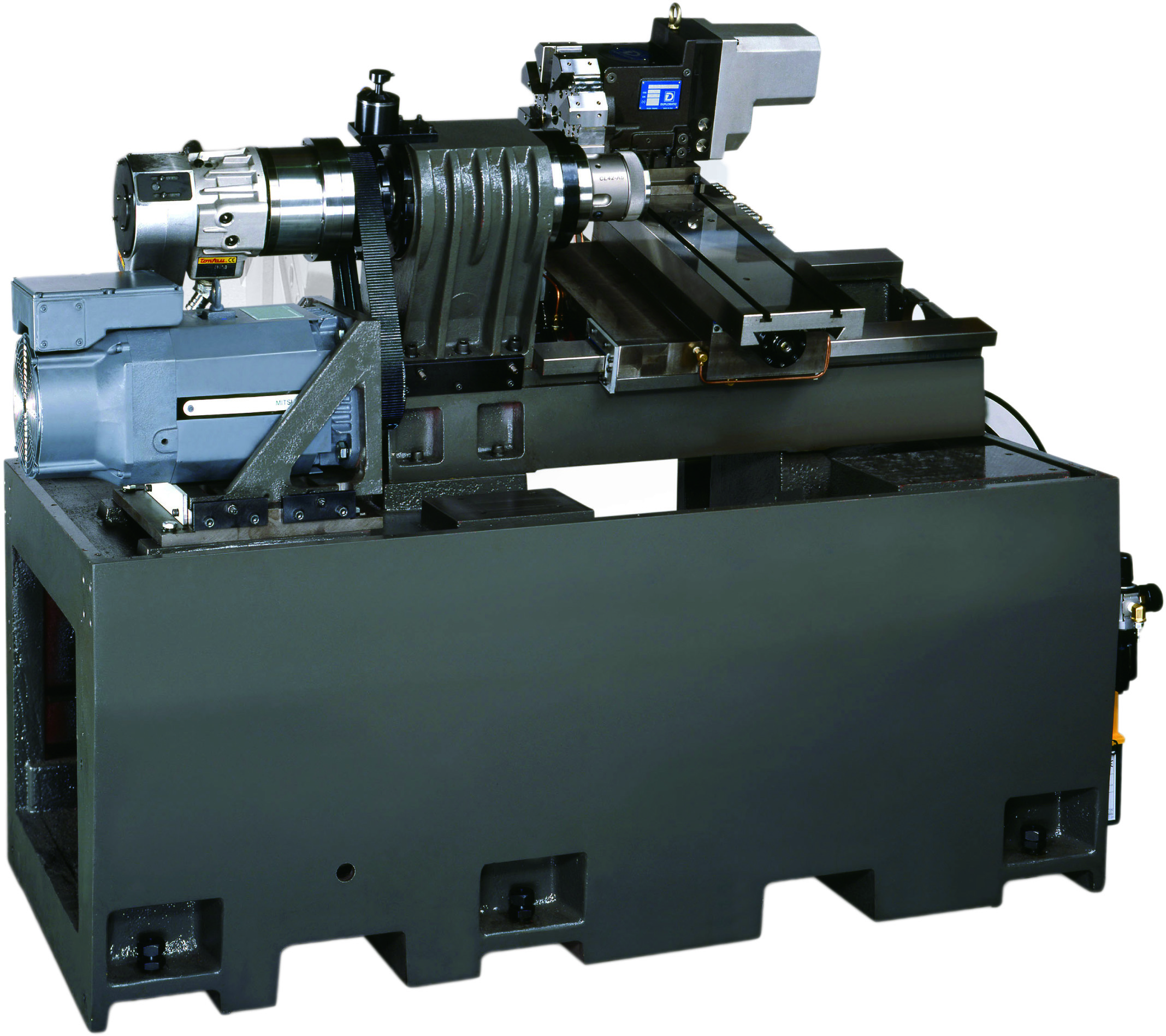

Optimized Structure Design!

Maximum Stability!! Maximum Rigidity!

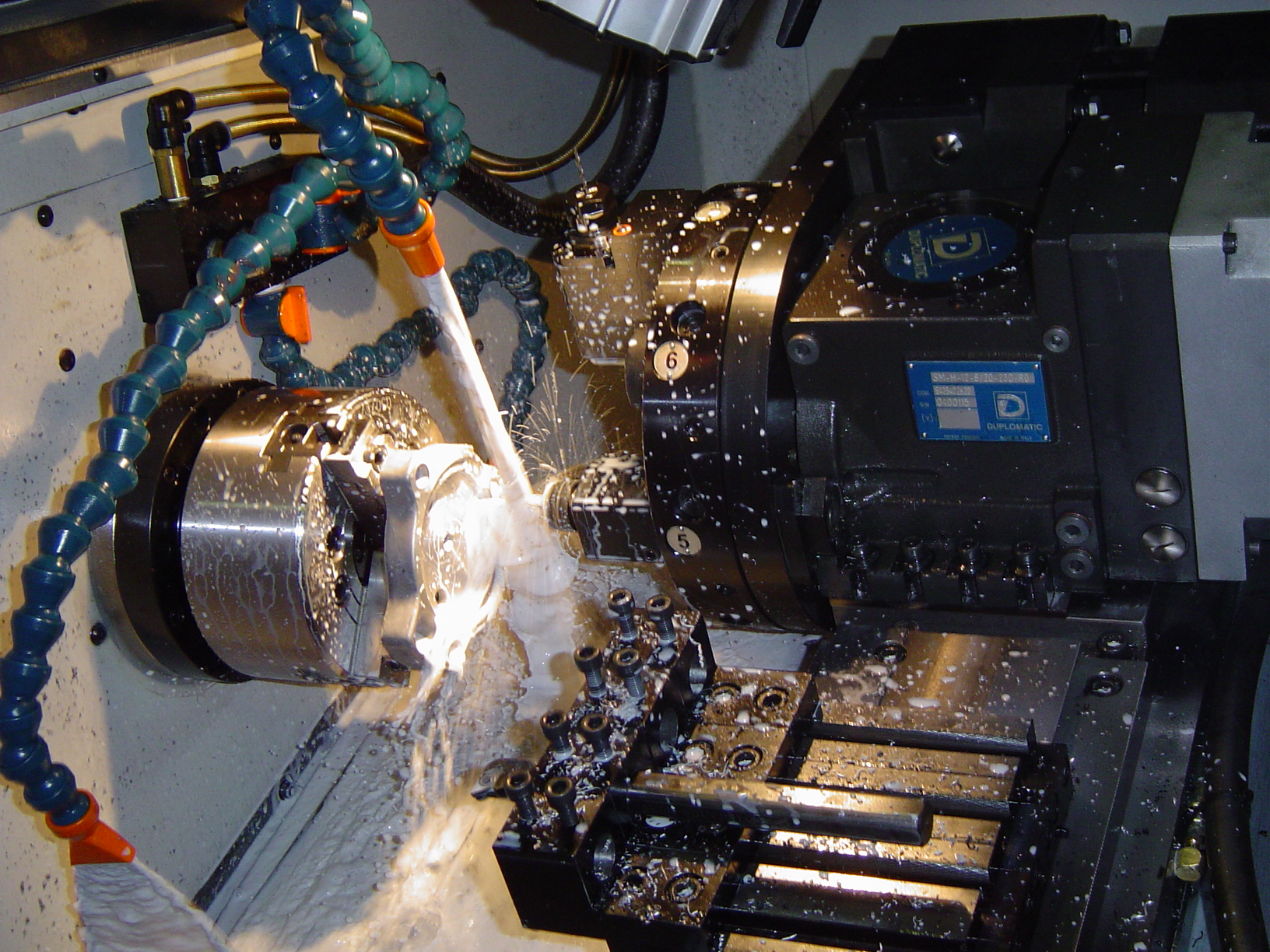

The machne structure is precision and ruggedly that is constructed from high quality casting iron. Slideways are hardened and precision ground. Slide is precision machined from alloy steel to ensure service life and high accuracy.

High Precision C1 class and C3 class ball screws on X,Z-axes combined with extra solid support assure outstanding repeatability and positioning accuracy. The ball screws are forcibly lubricated to minimize thermal deformation while ensuring long service life.

15 Degree slant bed construction effectively reduces dividing force and backlash of ball screw on X-axis movement, while ensuring machining accuracy at all times.

| MODEL | UNIT | FTC-10 |

| Swing Over Bed | mm | 250 |

| Swing Over Top Slide | mm | 120 |

| Distance Between Center | mm | N/A |

| MAX. Turnable O.D. | mm | 90 |

| MAX.Turnable Length | mm | 120 |

| Angle of the Machine bed | Degree | 15 |

| AC Spindle Motor | AC 7.5KW/10 HP | |

| Max. Spindle Speed | RPM | 100~5000 |

| Spindle nose | ISO | A2-5 |

| Spindle Hole | mm | 52 |

| Through Bar Capacity | mm | 42 |

| Spindle Front Bearing I.D. | mm | 70 |

| Chuck Size | inch | 6"(F-48C) |

| Tailstock Taper | MT | N/A |

| Tailstock Quill Diameter | mm | N/A |

| Tailstock Quill Travel | mm | N/A |

| Tailstock Seat Travel | mm | N/A |

| X-Axis Travel | mm | 250 |

| Z-Axis Travel | mm | 250 |

| X-Axis Rapid Speed | m/min | 15 |

| Z-Axis Rapid Speed | m/min | 15 |

| Min. Input Increment | mm | 0.001 |

| Square Shank Tools Size | mm | 20 |

| Max. Boring Tool Diameter | mm | 20 |

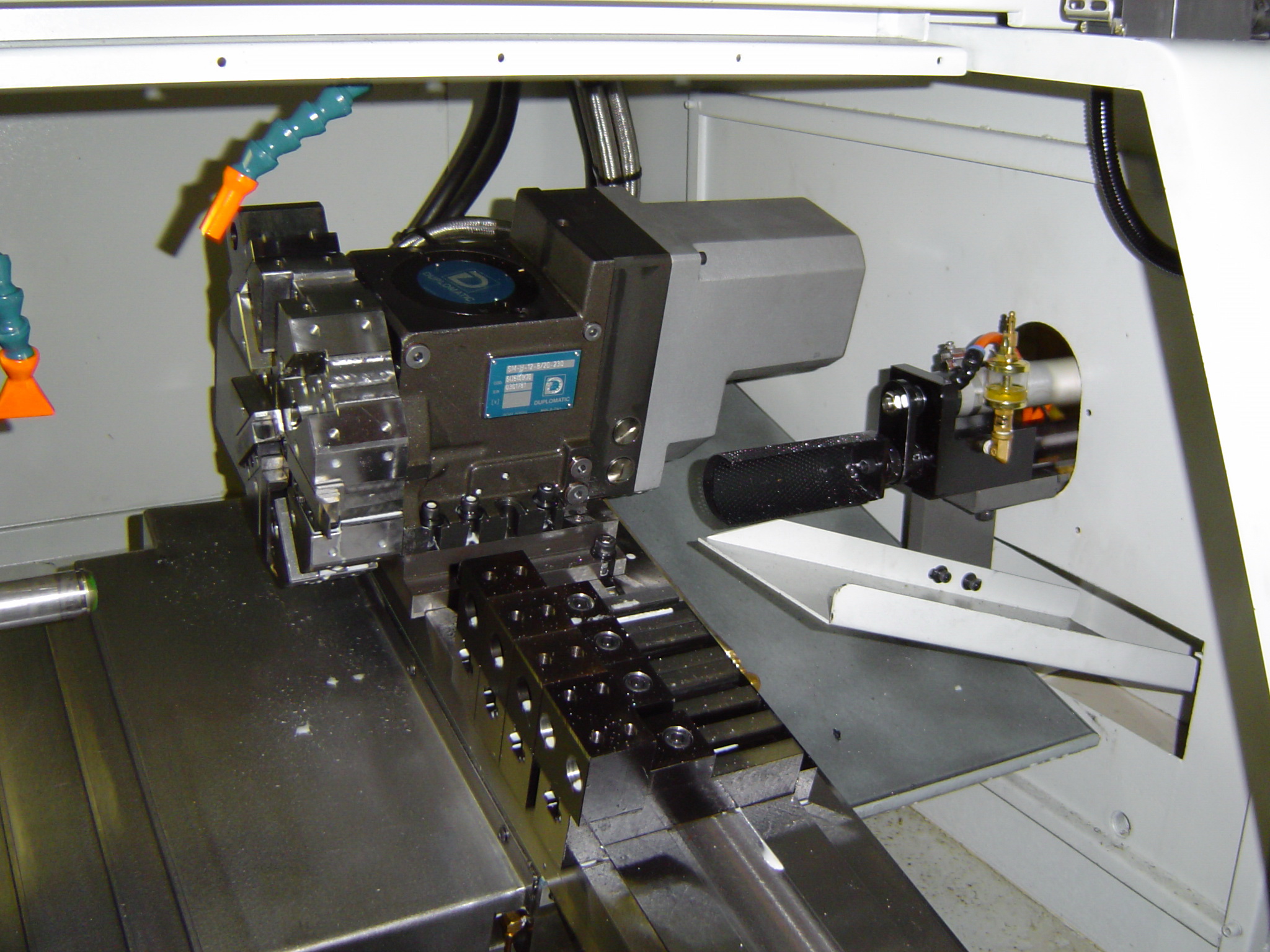

| Numbers of Tool Position | 8+Gang | |

| Change Tool Times | sec | 1.1 |

| Coolant Pump Motor | HP | 1/2 |

| Machine Dimension | mm³ | 2000*1350*1650 |

| Floor Space | mm² | 2500*3000 |

| Packing Dimension | mm³ | 2640*1600*2250 |

| Machine Net Weight | kg | 2150 |

| Machine Gross Weight | kg | 2400 |

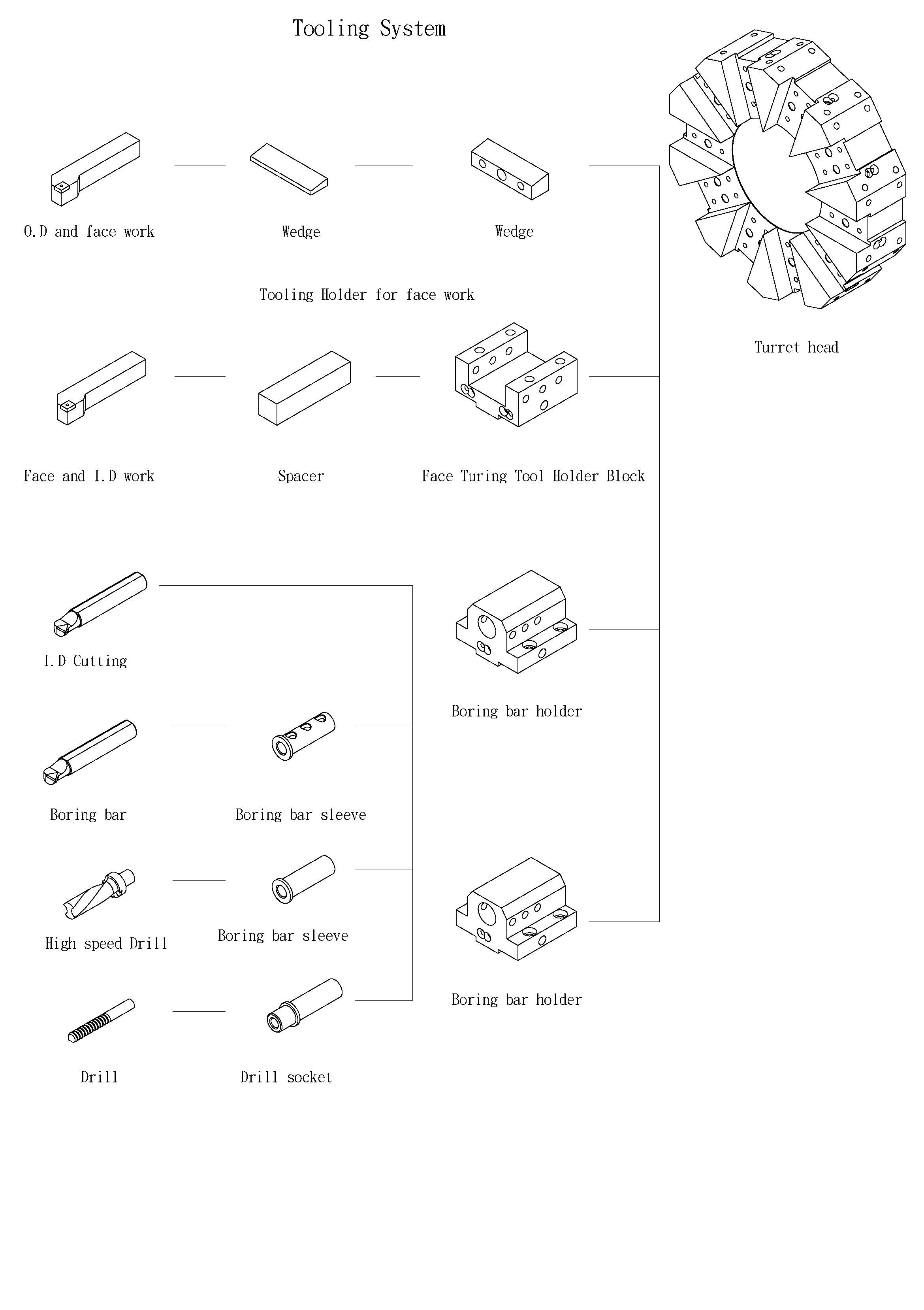

- 6" 3-Jaws hydraulic Chuck

- 8 tools hydraulic servo turret

- Facing Tool Holder 1 pc

- Boring bar tool holder 3 sets

- I.D. Sleeve 8, 10, 12,16mm / each 1 pc

- Soft Jaw 1 set

- Removable coolant Tank

- Coolant system

- Heat Exchanger for electrical cabinet

- Foot Switch

- RS-232 Interface

- Work Lamp

- Levelign bolts and pads

- Tool box with Tool kits

- Machine and electrical operation manual

- Bar feeder interface

- Gang Tool System front the turret

- Parts Catcher

- Workpiece conveyor

- Tool presetter

- Chip Conveyor and moving Cart

- Spindle Air Blow

- Auto power off

- Collet Chuck system (Dia.42mm or Dia. 52mm)

- Transformer

.jpg)