3YRS

AEGIS PRECISION MACHINERY CO., LTD.

Products

HORIZONTAL CNC LATHE

AEGIS FTC-35

FTC-35

Reflect Perfect Turning Ability!

Artistic design with complete extended function!!

45 degree slant bed construction ensures maximum stability and convenient chips disposal.

Powerful spindle motor. High torque output at low speed is excellent for heavy duty machining.

Fast tool change - in only less than one second.

Fully enclosed splash guard provides operational safety.

Bed is made of Meehanite cast iron.

High precision ball screw assures backlash free fransmission.

Specification

| Model | FTC-35/3000 |

| TRAVEL | |

| X-axis Travel | 330mm |

| Z-axis Travel | 3200mm |

| SPINDLE | |

| Spindle Nose | A2-11 |

| Spindle Speed (Belt type) | 1800 RPM |

| Through Bar Capacity | Ø117 mm |

| Max. Turning Dia. | 570 mm |

| SPEED | |

| Rapid Speed (X-axis) | 10 m/min |

| Rapid Speed (Z-axis) | 6 m/min |

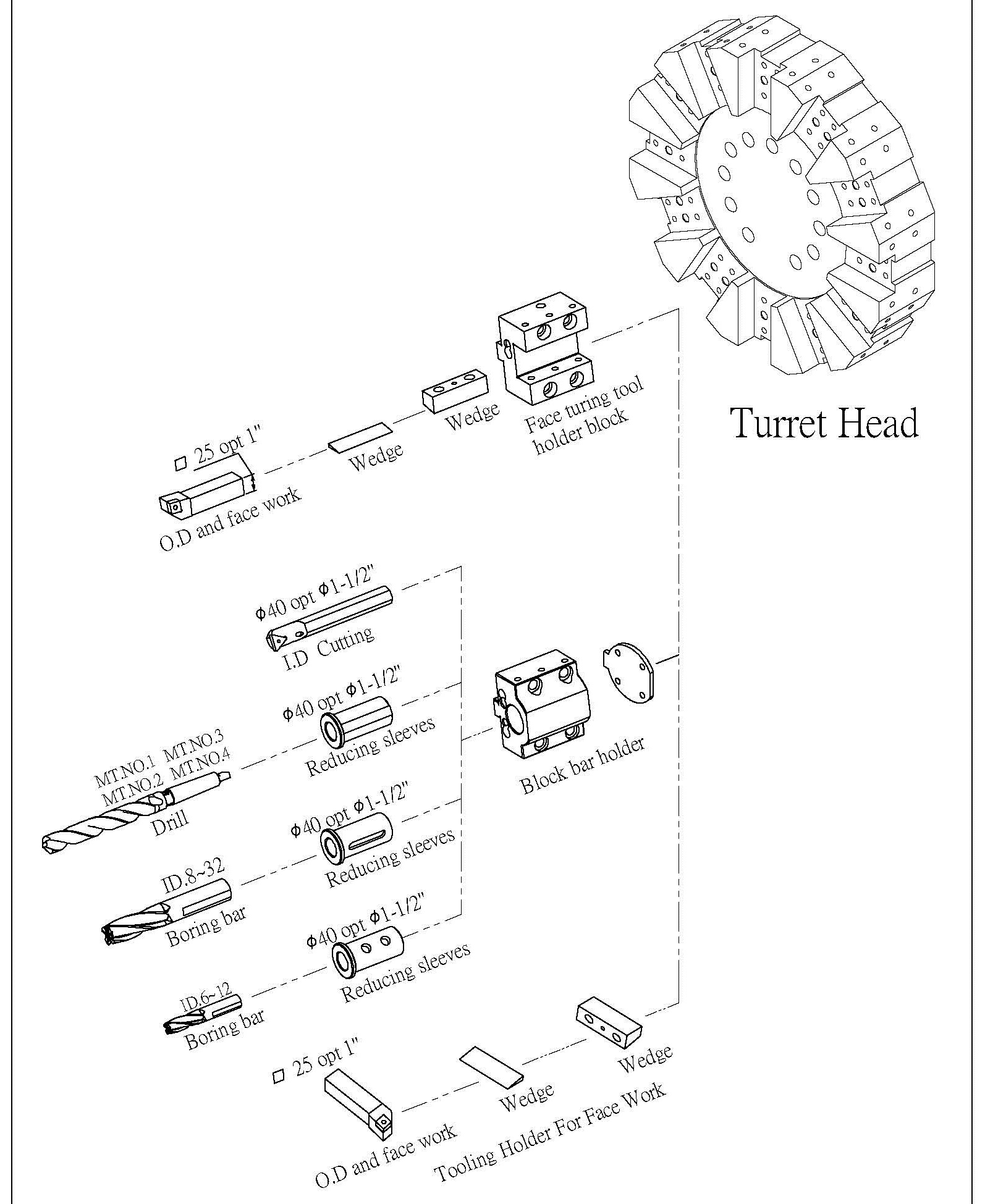

| TOOLING SYSTEM | |

| Tool Positions | 12 |

| Square Shank Tool Size | □25 mm |

| Max. Boring Tool Dia. | 40 mm |

| MOTOR SYSTEM (FANUC) | |

| Spindle Power (30min/norm) | 22kw (α22/7000i) |

| X-axis Power | 4.0 KW (α22/3000i) |

| Z-axis Power | 4.0 KW (α22/3000i) |

| TAILSTOCK | |

| Quill Diameter | 115 mm |

| Quill Travel | 150mm |

| Quill Tapper | MT #6 |

| OTHER | |

| Distance between center | 3200mm |

| Power | 55 KVA (Fanuc) |

| Weight | 11800 KG |

| Packing Dimension (LxWxH) | 7425x2055x2107 mm |

- 12 positions Static Turret (SAUTER440.220/SW384)

- Controller: Main Spindle motor 22kw (α22/7000i) / Manual Guide I and thread repaie

- Coolant system

- Work lamp

- Auto lubrication system

- Tool box with tool kits

- Warning Lamp

- Heat exchanger for the electric cabinet

- Standard Hard Jaw and soft jaw

- Foot switch for hydraulic chuck

- MT #6 Dead Center

- Chip conveyor with remove cart (Front side only)

- Fully enclosed splash guard

- Electron Hand Wheel

- Transformer

- Foundation and levelling kit / Maintenance Tool kit

- Operation and Maintenance Manuals

- Tailstock (Carriage Driven Movement) Hydraulic power quill in and out

- Hydraulic Programmable Tailstock

- Manual Steady Rest Ø30~300mm (Carriage Driven movement)

- Hydraulic Steady rest Ø12~152mm (Carriage Driven movement) Brand:SMW SLU-Z 3

- Hydraulic Steady rest Ø12~152mm (Hydraulic motor Driven movement) Brand:SMW SLU-Z 3

- Hydraulic Steady rest Ø50~200mm (Carriage Driven movement) Brand:SMW SLU-Z 3.2

- Hydraulic Steady rest Ø50~200mm (Hydraulic motor Driven movement) Brand:SMW SLU-Z 3.2

- Hydraulic Steady rest Ø65~235mm (Carriage Driven movement) Brand:SMW K-Z 3

- Hydraulic Steady rest Ø65~235mm (Hydraulic motor Driven movement) Brand:SMW K-Z 3

- Hydraulic Steady rest Ø12~160mm (Carriage Driven movement) Brand: ATLING AX4i

- Hydraulic Steady rest Ø12~160mm (Hydraulic motor Driven movement) Brand: ATLING AX4i

- Hydraulic Steady rest Ø20~200mm (Carriage Driven movement) Brand: ATLING AX5i

- Hydraulic Steady rest Ø20~200mm (Hydraulic motor Driven movement) Brand: ATLING AX5i

- Hydraulic Steady rest Ø30~255mm (Carriage Driven movement) Brand: ATLING AX6i

- Hydraulic Steady rest Ø30~255mm (Hydraulic motor Driven movement) Brand: ATLING AX6i

- Upgrade to 3-jaw hydraulic chuck 18" (wedge type non through-hole)

- Upgrade to 3-jaw hydraulic chuck 15" (wedge type through-hole)

- Upgrade to 3-jaw hydraulic chuck 18" (wedge type through-hole)

- Quill pressure digital control system (2000kg)

- Oil Skimmer