20YRS

CHIAN CHANG MACHINE CO., LTD.

Products

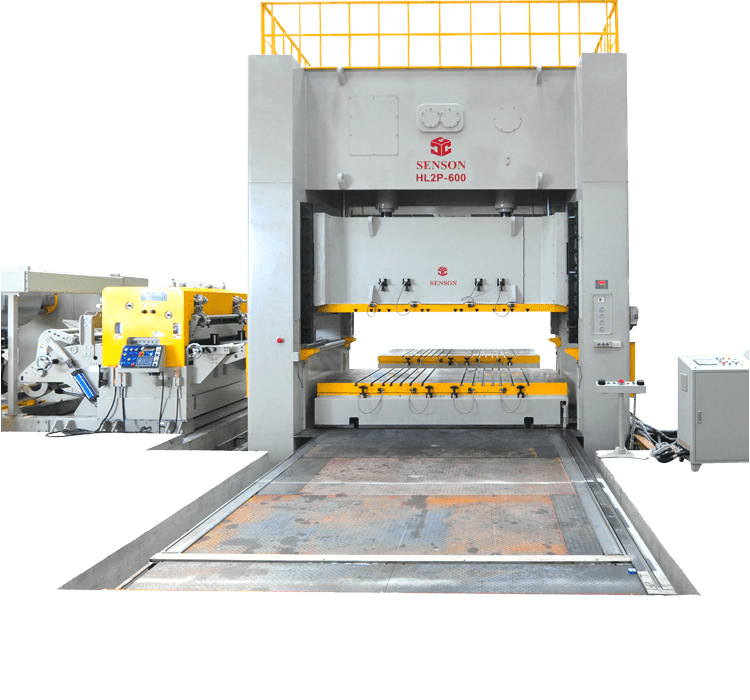

H-Frame Double Crank Link Motion Precision Power Presses

H-Frame Double Crank Link Motion Precision Power Presses

HL2P Series

200 ~ 600 tons

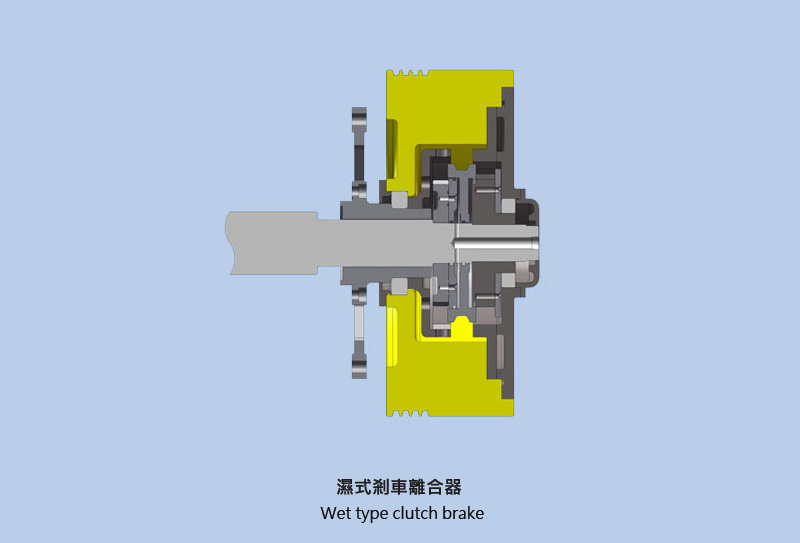

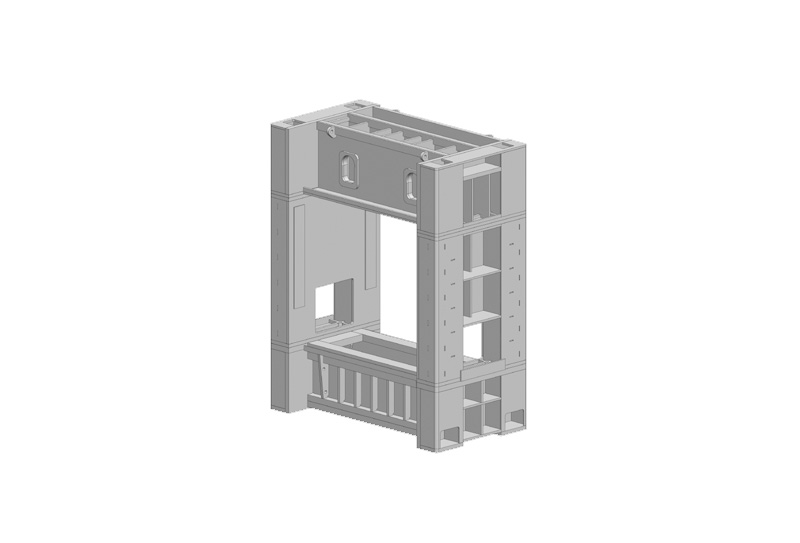

High rigidity frame, link motion and processing characteristics, advanced multifunctional controller, wet type clutch brake, and eight-face wide-and-long guide rail.

Specification

- Eight-face wide-and-long Guide Rail

- High Rigidity Frame

- Advanced Multifunctional Controller

- Link motion and processing characteristics

- Wet Type Clutch Brake

- Stamping Time Curve Comparison Chart

- Touch Screen Control Panel

- Single/Two-hand Push Button Operation Stand

Standard Accessories

| Operation mode ("off", "inching"/"single"/ "safe single"/"continuous") | Wet type clutch brake | Counter balancer(Equilibrating cylinders) |

| Motorized slide adjuster | Die height indicator | Pre-date/month/year production performance recorder |

| Encoder | 360°Crank angle LED display | S.P.M. display |

| Product lot counter (Preset,6-digit) | Total counter(Preset,6-digit) | Brake angle monitor device |

| Cutting outlet:2-set | Spare electronic rotary cams:5-set | Mileage maintenance reminder |

| Forced-circulation oil-lubrication systems | Inverter | "FOR." & "REV." modes for main motor |

| Power take-off feed shaft (feed direction:left→right ) | Air source socket | Power socket 220V,5A(for overseas market) |

| Portable push button operation stand | Air ejector | Rubber mount (Shock absorber) |

| Maintenance tools with box | Operation Manual |

| Safety devices for protecting workers or tools | |||

|---|---|---|---|

| Hydraculic overload protector | Mis-feed detective circuit: 4-set (2A, 2B) | Anti-repeat device (Overrun detector) | Safety light curtain |

Optional Accessories

| Safety light curtain | Pneumatic die cushion | Hydraulic die cushion |

| Air feeder | Roll feeder | Auto material straighter |

| Quick die change system: die lifter, die arm, etc. | Foot switch |

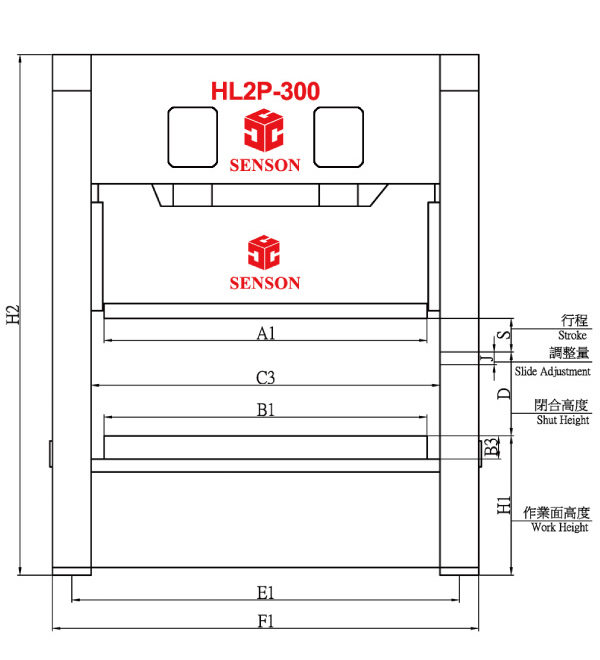

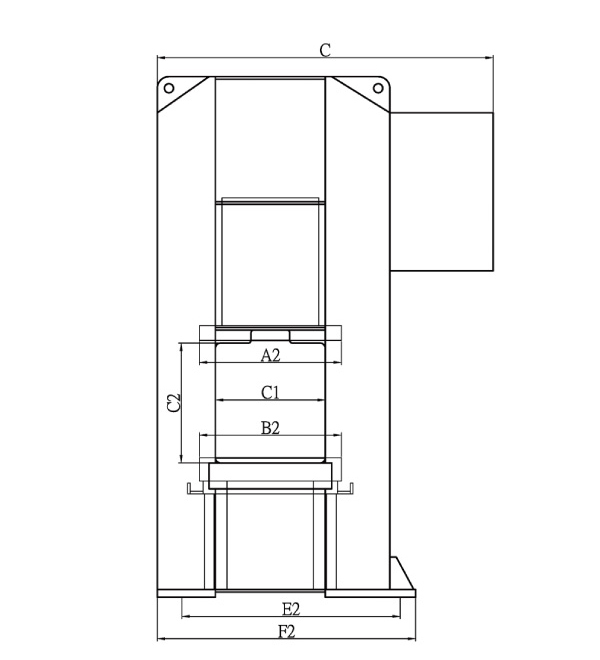

Major Dimension

| Model | A1 | A2 | B1 | B2 | C | C1 | C2 | C3 | D | E1 | E2 | F1 | F2 | H1 | H2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HL2P-200 | 1920 | 900 | 2100 | 900 | 1600 | 660 | 780 | 2200 | 500 | 2500 | 1570 | 2800 | 1880 | 1000 | 3850 |

| HL2P-300 | 2500 | 1100 | 2600 | 1200 | 2810 | 820 | 1030 | 2700 | 650 | 3000 | 1800 | 3300 | 2110 | 1080 | 4310 |

| HL2P-400 | 2600 | 1200 | 2600 | 1200 | 2985 | 1060 | 1140 | 2840 | 700 | 3260 | 2200 | 3680 | 2610 | 1200 | 5070 |

| HL2P-600 | 3200 | 1800 | 3200 | 1800 | 3565 | 1430 | 1160 | 3460 | 800 | 4100 | 2500 | 4580 | 2900 | 1860 | 6000 |

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HL2P-200 | 1920 | 900 | 300 | - | - | 2100 | 900 | 150 | 300 | - | 48 | 28 | 20 | 29 | ||

| HL2P-300 | 2500 | 1100 | 300 | - | - | 2600 | 1200 | 150 | 300 | 900 | 320 | - | 48 | 28 | 20 | 29 |

| HL2P-400 | 2600 | 1200 | 300 | - | - | 2600 | 1200 | 150 | 125 | 1012 | 400 | - | 37 | 22 | 16 | 19 |

| HL2P-600 | 3200 | 1800 | 350 | - | - | 3200 | 1800 | 250 | 125 | 825 | 600 | - | 46 | 28 | 20 | 23 |

| Model | HL2P-200 | HL2P-300 | HL2P-400 | HL2P-600 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity tonf |

200 | 300 | 400 | 600 | |||||

| Slide Stroke Length mm |

160 | 250 | 250 | 250 | |||||

| Strokes Per Minute (Variable Speed) S.P.M. |

30 - 70 | 20 - 50 | 20 - 60 | 20 - 60 | |||||

| Tonnage Rating Point mm |

6 | 7 | 8 | 10 | |||||

| Shut Height (S.D.A.U) mm |

500 | 650 | 700 | 800 | |||||

| Slide Adjustment mm |

120 | 150 | 200 | 250 | |||||

| Slide Bottom Area mm |

1900 x 900 | 2500 x 1100 | 2600 x 1200 | 3200 x 1800 | |||||

| Bolster Area mm |

2100 x 900 | 2600 x 1200 | 2600 x 1200 | 3200 x 1800 | |||||

| Bolster Thickness mm |

170 | 180 | 200 | 580 | |||||

| Work Heigh mm |

1000 | 1080 | 1200 | 1860 | |||||

| Frame Inside Width mm |

2200 | 2700 | 2840 | 3460 | |||||

| Overall Size mm |

2800 x 1880 | 3300 x 2110 | 3680 x 2630 | 4580 x 2900 | |||||

| Overall Height mm |

3850 | 4310 | 5070 | 6000 | |||||

| Main Motor(Variable Speed) HP(KW)xP |

25(19KW) x 4 | 40(30KW) x 4 | 60(45KW) x 4 | 75(56KW) x 4 | |||||

| Slide Adjust Motor HP(KW)xP |

2(1.5KW) x 4 | 5(3.75KW) x 4 | 5(3.75KW) x 4 | 7.5(5.6KW) x 4 | |||||

| Air Pressure kgf/cm2 |

5 | 5 | 5 | 5 |

PS. Based on the main factory production, rights of modification reserved. (Based on consumer requirement, make a specification.)