Products

V207 is new model 7 axes Swiss type CNC lathe with double Y axes tooling system smaller than W series. V series machine can process milling, tapping, drilling, and turning complexity parts for medial parts (especially for bone screw), electrical parts, automobile, clock/ watch, and aerospace..., etc..

We use FANUC control system. We always think about needs and conveniences from users, and then, we make more suitable and efficient machines, V series. The human-based and innovation are our important core design. The new experience by V series presented.

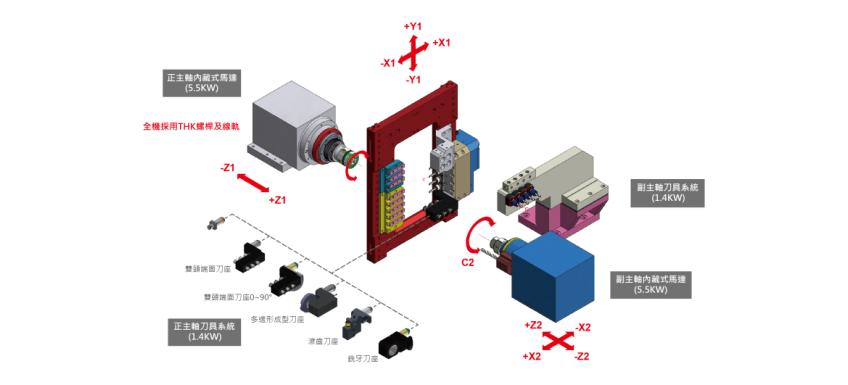

Strengths are as follows:

1.Rigidity structure design and powerful spindles bring more producing ability and machining performance.

2.Fast and heavy turning by powerful live tools. (see main structure list)

3.Special tooling holders for complicated jobs. (see optional accessories list)

4.Spindle chiller system makes stable temperature and good precision jobs. (see standard accessories list)

5.Hydraulic clamping spindles are easy adjustment. (see standard accessories list)

By high-rigidity and stable machine components, V Series is in a state of high-speed machining, high-precision quality, and low failure rate of Swiss turn machine.

The smart NC control technologies of Wivia that makes high productivity possible.

The rich variety tooling and power system that help operators to overcome each jobs.

Specification

|

Item |

Unit |

V127 |

V207 |

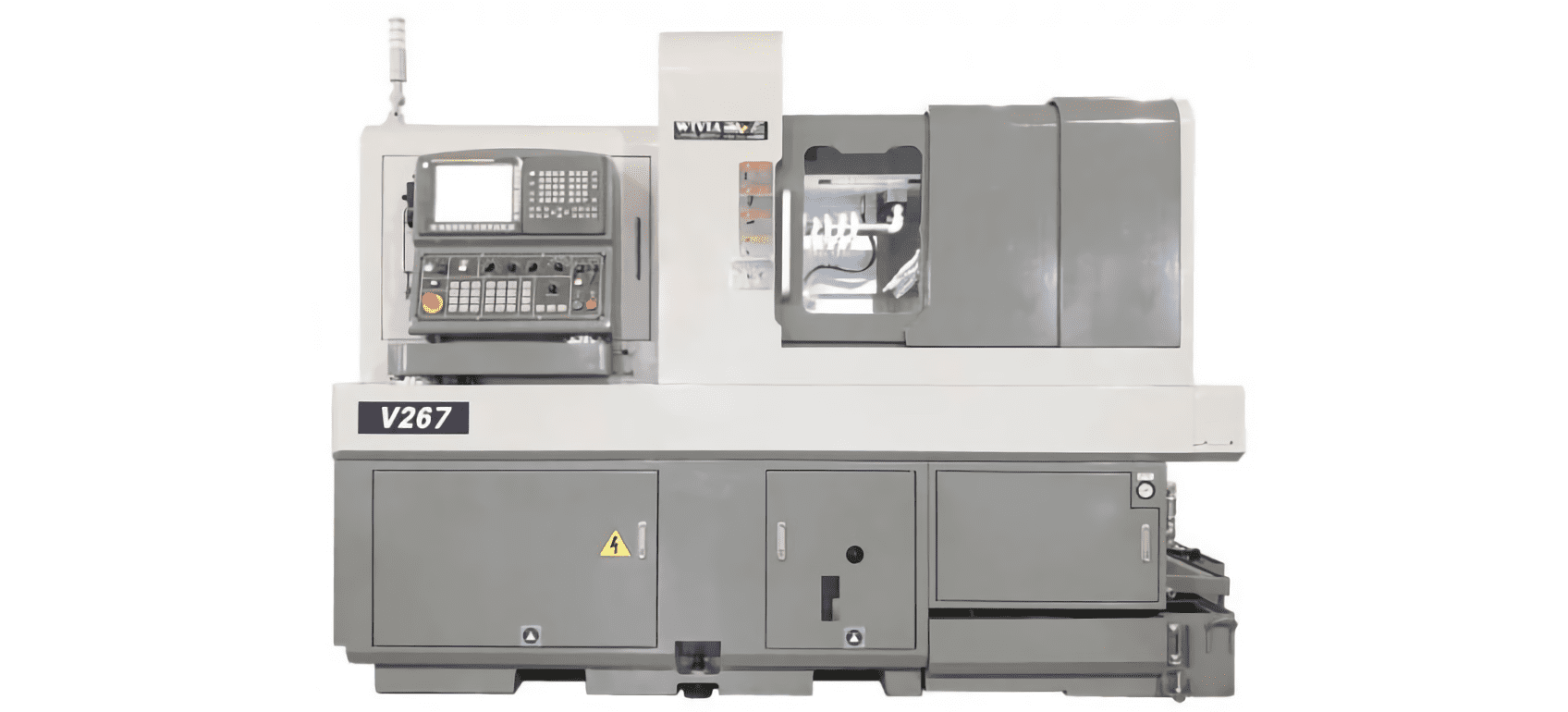

V267 |

Remark |

|

Max. turning dia. |

mm |

Ø12 |

Ø20 |

Ø26 |

|

|

Max. turning length (Rotary) |

mm |

220 |

220 |

220 |

one stroke |

|

Max. turning length (Fixed) |

mm |

240 |

240 |

240 |

|

|

Max. turning length |

mm |

30 |

50 |

65 |

|

|

OD tooling holder |

pcs |

6:□10 |

5: □12 |

5: □12 |

|

|

ID tooling holder |

pcs |

4/Ø25 |

4/Ø25 |

4/Ø25 |

|

|

Cross live tooling holder |

pcs |

5/ER16 |

5/ER16 |

5/ER16 |

|

|

Face live tooling holder |

pcs |

4/ER16 |

4/ER16 |

4/ER16 |

|

|

Sub spindle aside drilling tooling holder |

pcs |

1/Ø25 |

1/Ø25 |

1/Ø25 |

|

|

No. of axis controls (with C axis) |

pcs |

7 |

7 |

7 |

|

|

C axis control minimum |

degree |

0.001° |

0.001° |

0.001° |

|

|

Max. main spindle speed |

rpm |

10000 |

10000 |

8000 |

|

|

Max. sub spindle speed |

rpm |

10000 |

8000 |

8000 |

|

|

Main spindle motor |

KW |

2.2/3.7 |

3.7/5.5 |

3.7/5.5 |

built-in |

|

Sub spindle motor |

KW |

2.2/3.7 |

3.7/5.5 |

3.7/5.5 |

built-in |

|

Main spindle cooling |

|

Air cooling |

Air cooling |

Air cooling |

|

|

Sub spindle cooling |

|

Air cooling |

Air cooling |

Air cooling |

|

|

Main spindle clamping system |

|

Mechanical |

Mechanical |

Mechanical |

OP. Hydraulic |

|

Sub spindle clamping system |

|

Mechanical |

Mechanical |

Mechanical |

OP. Hydraulic |

|

Rapid traverse of X1/Z1/Y1/X2/Z2 |

M/min |

30 |

30 |

30 |

|

|

X1 axis motor |

KW/rpm |

0.75 / 4000 |

0.75 / 4000 |

0.75 / 4000 |

|

|

Z1 axis motor |

KW/rpm |

0.75 / 4000 |

0.75 / 4000 |

0.75 / 4000 |

|

|

Y1 axis motor |

KW/rpm |

1.4 / 5000 |

1.4 / 5000 |

1.4 / 5000 |

|

|

X2 axis motor |

KW/rpm |

0.75 / 4000 |

0.75 / 4000 |

0.75 / 4000 |

|

|

Z2 axis motor |

KW/rpm |

0.75 / 4000 |

0.75 / 4000 |

0.75 / 4000 |

|

|

Cross live tooling motor |

KW/rpm |

1.0 / 8000 |

1.4 / 8000 |

1.4 / 8000 |

|

|

Face live tooling motor of sub spindle |

KW/rpm |

1.0 / 8000 |

1.4 / 8000 |

1.4 / 8000 |

|

|

Lubrication tank |

L |

2 |

2 |

2 |

|

|

Air compressed pressure |

Mpa |

0.6 |

0.6 |

0.6 |

1 |

|

Air compressed flow |

L/min. |

20 ~ 160 |

20 ~ 160 |

20 ~ 160 |

5 |

|

Coolant tank |

L |

290L (100%) |

290L (100%) |

290L (100%) |

2 |

|

Machine dimension L x W x H |

mm |

2880x1387x1900 |

2880x1387x1900 |

2880x1387x1900 |

3 |

|

Weight |

KG |

3000 |

3150 |

3150 |

4 |

1. 0.6Mpa = 6kg/cm²

2. At least 90% full for machining.

3. Without chip conveyor.

4. Without coolant tank and pumps.

5. Air flow will be different by different options.